Are you tired of slow, risky, and labor-intensive mold handling processes? Imagine a solution that not only drastically reduces manual effort but also enhances safety and speeds up your production cycle. A mold upender is not just a piece of machinery; it’s a strategic upgrade that can revolutionize your manufacturing efficiency.

A mold upender significantly improves manufacturing efficiency by automating and streamlining the process of rotating heavy molds. This reduces manual handling, minimizes the risk of accidents and product damage, speeds up mold repositioning for maintenance or processing, and ultimately boosts overall productivity. Mold upenders are essential for modern manufacturing facilities looking to optimize their operations.

Let’s dive deeper into how a mold upender can transform your factory floor and bring about tangible improvements in efficiency, safety, and cost-effectiveness.

Streamlining Mold Handling with a Mold Upender

Picture your factory floor: heavy molds being maneuvered slowly, requiring multiple workers and posing safety risks at every turn. This traditional method is not only time-consuming but also a bottleneck in your production line. A mold upender offers a game-changing solution, turning a cumbersome process into a swift, safe, and efficient operation.

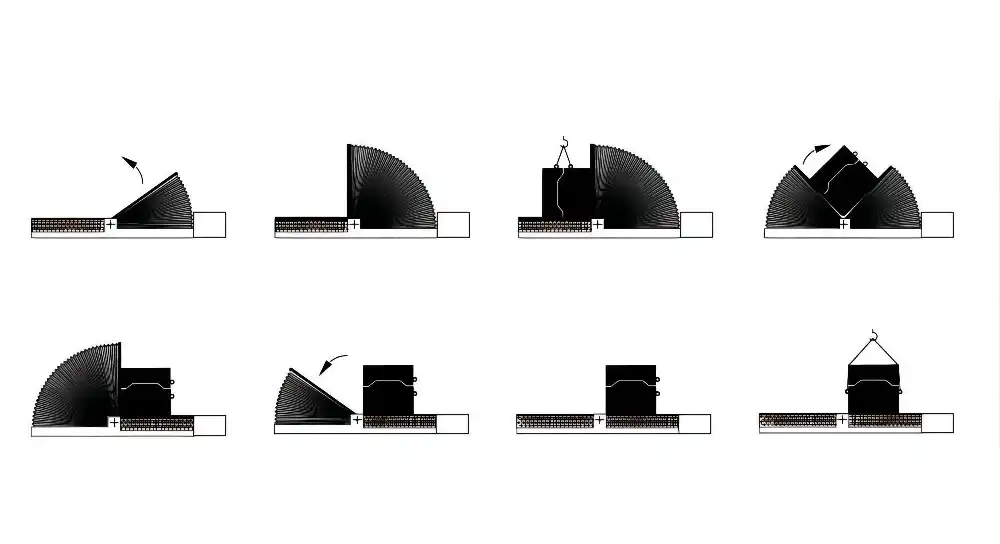

A mold upender streamlines mold handling by providing a controlled and mechanized way to rotate heavy molds 90 degrees. This eliminates the need for manual lifting and turning, significantly reducing the time and labor involved in repositioning molds for maintenance, storage, or integration into production lines. The result is a smoother workflow and increased throughput.

Dive Deeper into Operational Efficiency

To truly appreciate the efficiency gains from a mold upender, we need to dissect the traditional mold handling process and compare it to the streamlined approach offered by upender technology. Let’s break down the key areas where a mold upender makes a significant difference:

Time Reduction

Manual mold turning is notoriously time-consuming. It often involves multiple workers, specialized rigging, and slow, cautious movements to prevent damage and injury. In contrast, a mold upender completes the same rotation in a fraction of the time, often within minutes.

Labor Optimization

Traditional methods require a team of workers to manage heavy molds. This labor-intensive process not only increases operational costs but also ties up valuable personnel who could be deployed to more strategic tasks. A mold upender, operated by a single trained individual, frees up manpower and reduces labor expenses.

Safety Enhancement

The manual handling of heavy molds is inherently dangerous. The risk of dropped molds, worker strain, and accidents is ever-present. Mold upenders mitigate these risks by providing a secure and controlled rotation, significantly enhancing workplace safety and reducing potential liabilities.

To illustrate these points, consider the following comparison:

| Aspect | Traditional Method (Manual Handling) | Mold Upender System | Efficiency Improvement |

|---|---|---|---|

| Turn Time | 30-60 minutes | 5-10 minutes | 6x – 12x Faster |

| Labor Required | 2-4 workers | 1 operator | 50% – 75% Reduction |

| Safety Risk | High | Low | Significant Reduction |

| Damage Potential | Moderate to High | Low | Significant Reduction |

| Process Consistency | Variable | High | Improved Consistency |

As the data indicates, the implementation of a mold upender results in substantial improvements across critical operational metrics. The time savings alone translate to increased throughput and faster production cycles, directly boosting manufacturing efficiency.

Enhancing Product Quality Through Precise Mold Handling

In manufacturing, product quality is paramount. Damage to molds during handling can lead to defects in the final products, resulting in costly rework and scrap. Manual handling, with its inherent variability and risks, increases the likelihood of such damage. A mold upender, however, offers a solution by ensuring precise and controlled movement, safeguarding mold integrity and, consequently, product quality.

Mold tilters enhance product quality by providing precise and controlled movement of molds, minimizing the risk of damage during handling. This leads to fewer defects in manufactured parts, reduces rework, and ensures consistent product quality. The controlled rotation and positioning capabilities of a mold upender contribute directly to maintaining high production standards.

Precision Movement for Superior Output

The benefits of precise mold handling extend beyond just preventing damage. Consistent and accurate mold positioning is crucial for maintaining uniformity in the manufacturing process. Let’s explore how mold upenders contribute to enhanced product quality:

Controlled Rotation

Mold upenders offer a smooth and controlled 90-degree rotation. This eliminates jerky movements and sudden impacts that can occur with manual handling or crane-based methods. The controlled motion minimizes stress on the mold and its components, reducing the chance of misalignment or damage.

Minimized Human Error

Manual handling is susceptible to human error. Even with skilled operators, fatigue, miscommunication, or slight lapses in concentration can lead to mistakes. Automated mold upenders reduce the reliance on manual input, ensuring consistent and error-free operation every time.

Stable Positioning

Once rotated, a mold upender holds the mold securely in its new orientation. This stability is essential for subsequent operations like maintenance, repair, or integration into machinery. Stable positioning prevents accidental shifts or drops that could compromise mold integrity and product quality.

By ensuring precise movement and stable positioning, mold upenders contribute to a more reliable and consistent manufacturing process. This translates directly to higher product quality, reduced defect rates, and improved customer satisfaction.

Cost Savings Realized Through Mold Upender Implementation

Beyond efficiency and quality improvements, the implementation of a mold upender delivers significant cost savings across various operational areas. By reducing labor needs, minimizing damage, and increasing throughput, mold upenders offer a compelling return on investment for manufacturing businesses.

Manufacturers gain substantial cost savings from mold upenders by automating mold turning processes. This automation reduces labor costs, minimizes workplace accidents and associated expenses, increases production throughput, and decreases mold damage and repair costs. The cumulative effect is a significant improvement in the bottom line and a quicker return on investment.

Financial Advantages of Automation

The financial benefits of integrating a mold upender into manufacturing operations are multifaceted. Let’s examine the key areas where cost savings are realized:

Labor Cost Reduction

As previously discussed, mold upenders significantly reduce the need for manual labor in mold handling. This translates directly to lower wage expenses, reduced overtime costs, and decreased expenses related to employee benefits and training.

Reduced Accident-Related Costs

Workplace accidents, especially those involving heavy equipment, can be incredibly costly. These costs include medical expenses, compensation claims, potential legal fees, and production downtime. By enhancing safety, mold upenders minimize the risk of accidents and the associated financial burdens.

Increased Throughput and Production Volume

The efficiency gains provided by mold upenders lead to faster mold turnaround times and increased production throughput. This higher production volume, achieved without a proportional increase in labor or other costs, directly boosts revenue and profitability.

Minimized Mold Damage and Repair Expenses

Damage to molds can be expensive to repair, and in some cases, may necessitate complete mold replacement. The controlled handling offered by mold upenders reduces the likelihood of mold damage, minimizing repair and replacement costs and extending the lifespan of valuable mold assets.

Consider the financial impact summarized below:

| Cost Aspect | Impact of Mold Upender Implementation |

|---|---|

| Labor Costs | Significant Reduction |

| Accident-Related Expenses | Substantial Decrease |

| Mold Repair Costs | Lower |

| Production Throughput | Increase |

| Overall Operational Costs | Reduced |

The cumulative effect of these cost savings makes mold upenders a financially sound investment for manufacturers seeking to improve their bottom line. The initial investment in the equipment is quickly offset by the ongoing operational savings and efficiency gains.

Choosing the Right Mold Upender for Your Manufacturing Needs

Selecting the appropriate mold upender is crucial to maximizing its benefits. The market offers a variety of upender types and configurations, each suited to different applications and mold specifications. Understanding these options is key to making an informed decision.

The right mold upender depends on specific manufacturing needs, including mold size and weight, available floor space, and integration requirements with existing systems. Factors to consider include load capacity, rotation mechanism (hydraulic or mechanical), control system options (manual or automated), and customization possibilities to suit unique operational demands. Choosing the correct upender is essential for optimal efficiency and safety.

When considering a mold upender, evaluate these key factors:

- Load Capacity: Ensure the upender’s capacity meets or exceeds the weight of your heaviest molds. Overloading can lead to equipment damage and safety hazards.

- Rotation Mechanism: Hydraulic systems offer smooth, controlled rotation for heavy loads, while mechanical systems may be suitable for lighter molds.

- Control System: Automated controls enhance efficiency and reduce operator fatigue, while manual controls may be sufficient for simpler applications.

- Customization: Look for manufacturers who offer customization options to tailor the upender to your specific mold types, workflow, and space constraints.

- Safety Features: Prioritize upenders with robust safety features, such as emergency stop buttons, safety interlocks, and overload protection.

- Durability and Reliability: Choose a reputable manufacturer known for producing durable and reliable equipment to ensure long-term performance and minimize downtime.

By carefully assessing your specific needs and considering these factors, you can select a mold upender that will seamlessly integrate into your manufacturing process and deliver optimal efficiency, safety, and cost savings.

Investing in a mold upender is a strategic decision that yields substantial returns. By automating and streamlining mold handling, manufacturers can achieve significant improvements in efficiency, product quality, and cost-effectiveness. Mold upenders are not merely equipment; they are enablers of optimized manufacturing processes and enhanced operational excellence. For businesses striving for peak performance in today’s competitive landscape, a mold upender is an indispensable asset.

Conclusion

Implementing a mold upender offers transformative mold upender benefits to manufacturing operations. From enhanced efficiency and improved safety to significant cost savings and superior product quality, the advantages are undeniable. By streamlining mold handling processes, mold upenders empower manufacturers to optimize their workflows, reduce operational bottlenecks, and achieve new levels of productivity and profitability.