Operating forklifts safely when handling metal coils is paramount to prevent workplace accidents and material damage. This guide outlines essential forklift operation procedures, coil-specific handling risks, and safety measures including proper wrapping techniques to ensure secure coil transport and storage in any facility. Prioritizing these safety protocols protects personnel, equipment, and valuable coil inventory.

The Imperative of Forklift Safety in Coil Handling

Metal coils present unique challenges in material handling due to their weight, shape, and potential for instability. Forklifts, while versatile, require skilled operation and adherence to strict safety protocols to manage these heavy, cylindrical loads effectively. Neglecting safety during coil transport and wrapping can lead to serious consequences, including workplace injuries, equipment damage, and costly material waste. This article will delve into the crucial aspects of forklift safety tailored to coil handling environments, drawing from established safety guidelines and industry best practices.

Safe Forklift Operation: A Step-by-Step Guide for Coil Transport

Operating a forklift safely involves a series of well-defined steps, each critical to preventing accidents, especially when dealing with challenging loads like metal coils. The following sections outline these steps, focusing on the specific considerations for coil transport.

Safe Handling Preparation: Setting the Stage for Secure Coil Movement

Before even approaching a coil, proper preparation is essential. This phase focuses on assessing the load and the forklift itself to ensure a safe lift and transport operation.

Hazard Awareness: Identifying Potential Risks

Several hazards can arise during the preparation stage:

- Off-center loads: Coils, if not precisely centered, can cause forklift tip-overs or dropped loads.

- Overloading: Exceeding the forklift’s rated capacity is a direct path to instability and potential accidents.

- Damaged or loose loads: Compromised coil packaging or damaged coils themselves present significant handling risks.

Requirements and Best Practices for Safe Preparation

To mitigate these hazards, adhere to these recommended practices:

- Load Security is Paramount: Ensure the coil is securely arranged and stable before attempting to lift it. Damaged merchandise must be properly secured with wrapping or banding before transport.

- Centering the Load: Position the coil as centrally as possible on the forks. Exercise extreme caution when handling off-center loads that cannot be centered. Distribute the heaviest part of the coil closest to the forklift’s front wheels for enhanced stability.

- Weight Limits are Non-Negotiable: Absolutely do not overload the forklift. Know the forklift’s capacity and never exceed it. Capacity ratings are based on a specified load center. An off-center, improperly distributed, or oversized coil can easily exceed the forklift’s intended capacity.

- Utilize Load Extension Backrests: Employ load extension backrests to further stabilize loads and prevent them from sliding backward.

Approaching the Load: Precision and Caution

The approach to the coil is a critical maneuver demanding slow, deliberate actions to prevent collisions and ensure correct fork engagement.

Potential Hazards During Approach

- Speed: Approaching the coil too quickly increases the risk of collisions and loss of control.

- Rapid Turns: Sharp turns at speed can destabilize the forklift, particularly when unladen or preparing to lift a heavy coil.

Requirements and Recommended Practices for a Safe Approach

- Slow and Steady Wins the Race: Approach the coil slowly and with utmost care.

- Maintain Safe Distance: Stop approximately 20 to 30 cm (8 to 12 inches) in front of the coil.

- Square Alignment and Fork Height: Ensure the forklift is squarely positioned in front of the coil and that the forks are at the correct height for insertion.

- Neutral Gear and Parking Brake: Set the direction control to neutral once properly positioned.

- Stationary Fork Adjustments: Never raise or lower the forks while the forklift is in motion. Ensure the forklift is completely stopped and the brake is engaged before any fork adjustments.

- Overhead Clearance Awareness: Before raising the forks, always check for adequate overhead clearance. Vision becomes obstructed once the load is elevated, emphasizing pre-lift checks.

- Inching Pedal for Fine Positioning: Use the inching pedal to carefully creep the forklift closer to the stack for precise alignment.

Mast Position: Balancing Stability and Control

The mast’s tilt and position significantly impact load stability and forklift maneuverability, especially with heavy coils.

Potential Mast Position Hazards

- Tip-overs and Dropped Loads: Improper mast tilting, particularly with elevated forks or heavy coils, can lead to tip-overs and dropped loads.

Requirements and Best Practices for Mast Positioning

- Minimize Tilting: Exercise extreme caution when tilting the mast, especially with coils. Avoid forward tilting with elevated forks except when actively picking up or depositing a load. When stacking or tiering, tilt backward only enough to stabilize the coil.

- Maximum Capacity Coil Handling: When handling coils approaching the forklift’s maximum rated capacity:

- Tilt Back and Secure: Tilt the mast back and position the heaviest part of the coil firmly against the carriage.

- Travel with Tilt: Travel with the mast tilted back to maintain load stability throughout transport.

- Cautious Forward Tilt for Placement: Tilt the mast forward cautiously only when precisely positioning the coil onto a stack or designated location.

- No Forward Tilt During Travel: Never travel with the mast tilted forward. This increases the load distance from the forklift’s center of gravity, significantly reducing stability and increasing tip-over risk.

Fork Position: Secure and Balanced Engagement

Proper fork positioning is critical for securely lifting and transporting coils, ensuring balanced weight distribution and preventing slippage.

Potential Fork Position Hazards

- Tip-over: Incorrect fork placement or adjustments can contribute to forklift instability.

- Dropped Load: Inadequate fork engagement can lead to coils slipping off the forks during lifting or transport.

- Collision: Misjudging fork position can result in collisions with the coil itself, racking, or surrounding objects.

Requirements and Recommended Practices for Fork Positioning

- Level Forks for Insertion: Ensure the forks are level before inserting them into or under the coil or its pallet.

- Full Fork Engagement: Position the forks as far under the coil or pallet as possible. Forks should ideally extend at least two-thirds of the coil’s length or pallet depth for stable support.

- Pallet Stack Awareness: Be extremely careful to avoid driving the forks entirely through the pallet, especially in closely stacked pallet arrangements.

- Centering and Weight Distribution: Center the coil’s weight evenly between the forks. Adjust fork spacing as necessary to achieve balanced weight distribution. Fork positioners, whether manual or hydraulic, are valuable tools for precise adjustment.

- Mast Tilt for Stabilization After Engagement: After correctly positioning the forks, carefully tilt the mast back slightly to further stabilize the coil before lifting.

- Extra Caution with Off-Center Loads: Handle off-center coils with heightened caution due to the increased risk of tip-overs.

Lifting the Load: Controlled Ascent and Clearance Checks

Lifting the coil requires careful attention to clearance, controlled lifting speed, and securing the load against the backrest.

Potential Lifting Hazards

- Insufficient Clearance: Collisions with overhead obstructions like pipes, lights, sprinkler systems, or structures due to inadequate vertical clearance.

- Falling Loads: Insecurely positioned or unstable coils may shift or fall during the lifting process.

- Stuck Loads: Coils may become snagged or stuck on racking or other structures when lifted in confined spaces.

Requirements and Recommended Practices for Lifting

- Prior Clearance Check: Always verify adequate overhead clearance before initiating the lift. This is especially critical in confined spaces such as truck trailers or when high tiering coils. Ensure sufficient headroom under any overhead installations.

- Initial Lift and Clearance: Carefully lift the coil just above the lower stack or ground level, approximately 10 cm (4 inches), to ensure the load is free and clear of obstructions.

- Clearance and Back Tilt: Lift the coil to the necessary height and then tilt the mast back slightly to rest the coil securely against the load backrest extension. This provides additional stability during transport.

- Obstruction Monitoring: Continuously monitor the coil during lifting to ensure it does not catch or snag on any obstructions.

- Controlled Descent and Neutral Lever: Once lifted, slowly return the lift control lever to the neutral position to prevent jerky movements.

Lowering the Load: Smooth Descent and Controlled Positioning

Lowering the coil is the final step in transport and demands precision to avoid damage to the coil, the landing area, or forklift instability.

Potential Lowering Hazards

- Falling Loads: Coils can become unstable and fall during lowering if not properly controlled or positioned.

- Striking Objects: Collisions with the stack, racking, or other objects while lowering can damage the coil or surrounding environment.

Requirements and Recommended Practices for Lowering

- Mast Tilt for Stability: As with lifting, ensure the mast is carefully tilted backward to stabilize the coil throughout the lowering process.

- Load Security Re-verification: Re-confirm the coil is securely positioned on the forks before initiating movement for lowering.

- Controlled Backward Tilt: Carefully tilt the mast backward to maintain coil stability throughout the maneuver.

- Safe Distance from Stack: Slowly move the forklift to a position 20 to 30 cm (8 to 12 inches) away from the intended stack location or designated drop-off point.

- Complete Stop Before Lowering: Bring the forklift to a complete stop before initiating the lowering sequence.

- Vertical Mast for Lowering: Return the mast to the vertical position before commencing the actual lowering of the coil.

- Initial Lowering Height: Lower the coil so that its lowest point is approximately 15 to 20 cm (6 to 8 inches) above the floor or stacking surface.

- Safe Travel Height Maintenance: When transporting coils over distance, maintain this safe travel height to ensure stability and visibility.

High Tiering: Stacking Coils Vertically

High tiering, or stacking coils multiple tiers high, amplifies the risks associated with coil handling and requires extra precautions. Reach trucks are often utilized in high tiering operations.

Potential High Tiering Hazards

- Overloading: Exceeding forklift capacity at extended mast heights is a heightened risk in high tiering.

- Tip-over: Instability at height significantly increases the potential for tip-overs.

Requirements and Recommended Practices for Safe High Tiering

- Weight Distribution by Tier: Always place the heaviest coils on the bottom tier of the stack and progressively lighter coils on upper tiers to lower the center of gravity and enhance stability.

- Reduced Capacity at Height: Recognize and adhere to the forklift’s reduced load capacity as the mast is fully extended. Consult the forklift’s load capacity chart which typically accounts for height.

- Slow and Controlled Reach Extension: When depositing coils on upper tiers, extend the reach mechanism slowly and with extreme care, maintaining a smooth and controlled motion.

- Extreme Caution with Tilt: Exercise extreme caution when tilting the mast forward or backward, particularly at high tiering heights. Even minor tilts can drastically affect stability at elevation.

Truck Trailers and Railroad Cars: Unique Loading Dock Considerations

Loading and unloading coils from truck trailers and railroad cars introduce specific hazards related to the interface between the transport vehicle and the loading dock.

Potential Hazards at Loading Docks

- Falling off Loading Dock: Accidental falls from the loading dock edge are a serious risk.

- Moving Vehicles: Unintended movement of trucks or railroad cars during loading/unloading operations can lead to severe accidents.

- Slipping or Inadequate Dockboards: Dockboards that are slippery, damaged, or of insufficient strength can fail under forklift and coil weight.

Requirements and Recommended Practices for Loading Dock Safety

- Vehicle Immobilization: Crucially, ensure the brakes of highway trucks are firmly set, and wheel chocks are placed under the rear wheels to prevent any rolling during forklift operations. For railroad cars utilize wheel stops or other positive securing mechanisms to prevent movement.

- Trailer Support: Fixed jacks may be necessary to support semi-trailers and prevent upending, particularly if the trailer is not coupled to a tractor unit during loading/unloading.

- Dockboard Security: Ensure dockboards (bridge plates) are appropriately rated for the forklift and coil weight and are securely positioned to prevent slipping or movement. Portable dockboards must be anchored or equipped with anti-slip devices.

- Dockboard Strength: Portable and powered dockboards must be strong enough to bear the imposed load. Powered dockboards should adhere to Commercial Standard CS202-56 guidelines.

- Handholds on Portable Dockboards: Provide handholds or other effective means on portable dockboards for safe manual handling and positioning.

- Railcar Movement Prevention: Implement positive protection measures to prevent railroad cars from being moved while dockboards are in position.

- Trailer Floor Inspection: Always inspect the trailer floor to ensure it can adequately support the forklift and the coil’s weight before entering. Factor in floor thickness and cross-member spacing as thicker floors and closer spacing will increase load capacity.

- Door Height Clearance: Confirm the entry door height of the trailer provides sufficient clearance for the forklift, considering the height of the loading platform.

- Straight Approach on Dockboards: Drive straight across dockboards when entering or exiting truck trailers or railcars to minimize stress on the dockboard and maintain forklift stability. Avoid turning on dockboards.

- Lighting and Visibility: Use dock lights and forklift headlights when working in dark trailers to enhance visibility.

- Audible Warnings: Sound the forklift horn when entering or exiting trailers to alert personnel.

- Railroad Car Door Operation: Never use a forklift to open railroad car doors unless the forklift is specifically equipped with a device designed for this purpose, the operator is trained in its use, and all other personnel are clear of the area.

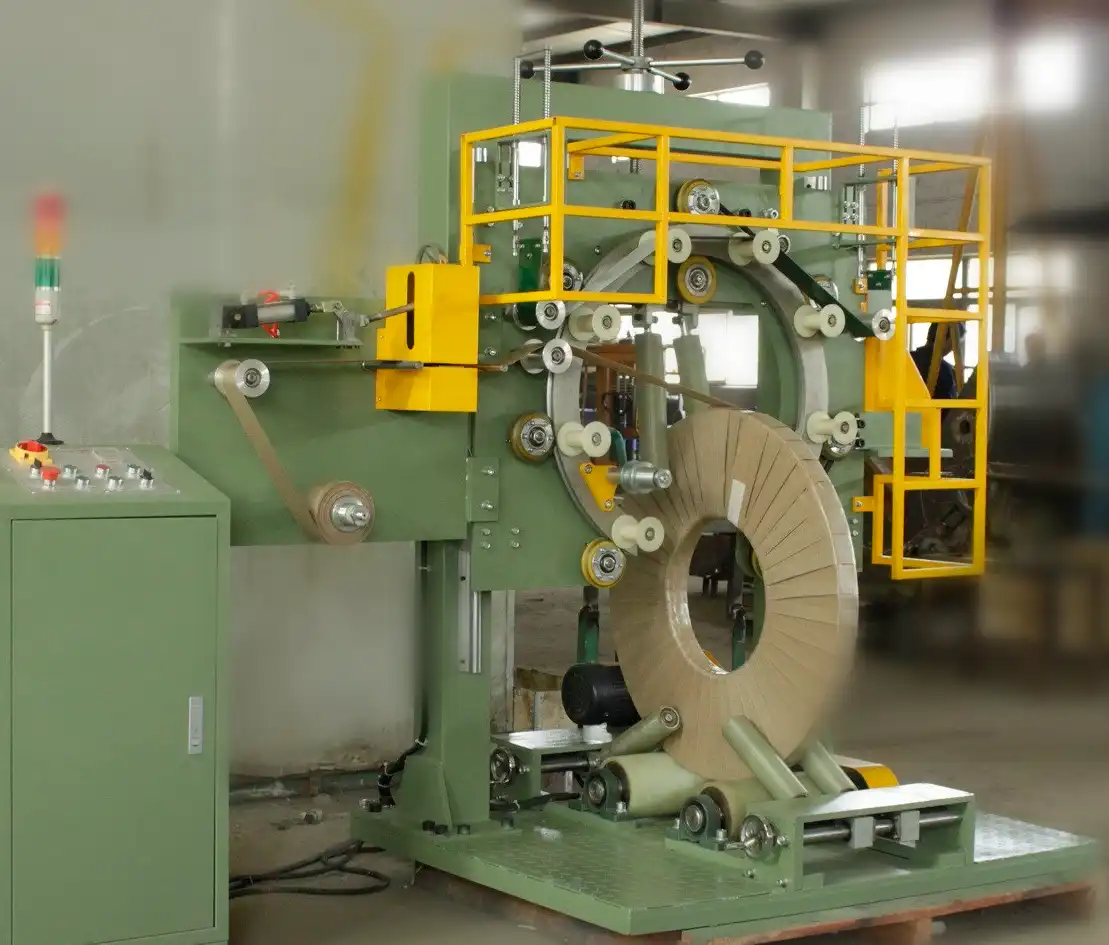

Coil Wrapping: An Integral Safety Component

Coil wrapping is not merely for aesthetic purposes; it plays a vital role in coil securement and protection during handling and storage.

- Secure Damaged Goods: Wrapping or banding is essential for securing damaged coils to prevent further unraveling and maintain load integrity during forklift transport.

- Stretch Wrapping Safety: When using stretch wrapping machines for palletized coils, start with a low rotational speed to prevent coils from shifting or falling during the wrapping process. Rotary arm wrapping machines, where the coil stack remains stationary, offer enhanced stability.

- Clearance During Machine Operation: Maintain a safe distance from stretch wrapping machines while they are in operation. Utilize emergency stop (E-stop) buttons to halt machine motion before making any adjustments to the stretch wrap itself.

Warehouse Safety: A Holistic Approach to Coil Handling Environments

Warehouse safety is not just about forklift operation, but encompasses the entire coil handling and storage environment.

- Trained Personnel: Ensure all personnel involved in coil handling are thoroughly trained in safe operating procedures for forklifts and coil handling equipment.

- Equipment Suitability: Utilize forklifts and coil handling attachments that are appropriately rated for the weight and dimensions of the coils being handled. Never use underrated equipment. Overrated equipment provides an added margin of safety.

- Fire Safety: Collaborate with local fire inspectors to establish fire safety protocols, especially regarding coil storage locations and heights. In the event of a fire, operators should be trained to avoid coil storage areas due to the risk of collapsing coil stacks.

- Ongoing Refresher Training: Implement regular refresher training on forklift safety and coil handling best practices to reinforce safe habits and address complacency that can develop over time.

- Quality Control and Damage Prevention: Emphasize quality control throughout the coil handling process. Minimize double-handling of coils, as each lift increases the risk of damage. Even minor nicks or blemishes, especially on coil edges, can lead to significant material waste and production inefficiencies.

Conclusion: Prioritizing Safety for Efficient Coil Handling

Safe forklift operation during coil transport and wrapping is not just a set of rules; it is a fundamental commitment to protecting personnel, preserving material quality, and ensuring efficient operations. By diligently adhering to these guidelines, facilities can significantly mitigate the risks associated with coil handling, creating a safer and more productive work environment. Consistent training, proactive hazard awareness, and a strong safety culture are the cornerstones of successful and safe coil handling practices.