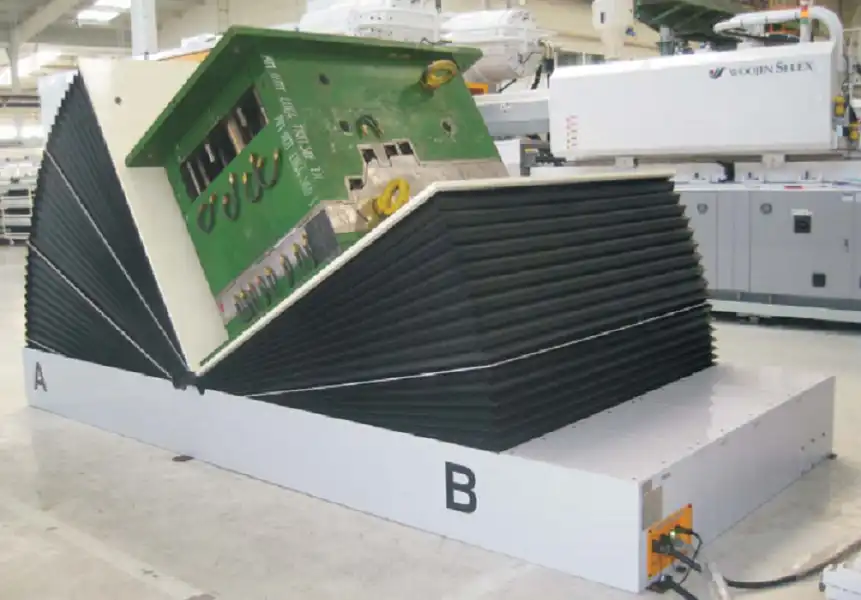

Is your manufacturing facility struggling with high labor costs? The modern manufacturing world demands efficiency. A mold flipping machine could be the answer to your challenges. Imagine a system like this fitting into your workflow, transforming tedious manual labor into a smooth automated process. It promises to save time, reduce labor costs, and ensure safety.

A mold flipping machine can significantly reduce labor costs by automating the tedious task of mold handling. This machine ensures speed and precision, reducing the need for manual labor. By automating this process, companies can cut down on human error, reduce the risk of workplace injuries, and streamline operations, leading to both time and cost savings.

As someone who’s seen firsthand the evolution of manufacturing, I recognize the power of automation in molding processes. With efficiency being the focal point of most operations, it’s crucial to embrace technology that offers precision and saves costs simultaneously. I invite you to explore the practical advantages of investing in such equipment.

1. How Do Mold Flipping Machines Enhance Labor Efficiency?

Mold handling is a complex task that demands precision and strength. Mold flipping machines relieve workers from physically demanding tasks, allowing them to focus on more strategic roles. The automation of mold flipping ensures a quicker turnaround and enhances overall production efficiency, making it an attractive proposition for any manufacturer aiming for cost reduction.

Mold flipping machines use modern technology to perform precise mold 180 degree turning tasks efficiently. By automating the mold flipping process, these machines reduce the need for manual intervention, leading to fewer workplace accidents and higher productivity. The integration of such technology in manufacturing helps in maintaining consistent product quality while simultaneously enhancing labor efficiency.

Understanding Mold Flipping Machines Through Efficiency Data

The integration of mold flipping machines in manufacturing isn’t just about cutting costs; it’s about refining processes in a data-driven manner. For instance, in our experience, introducing these machines reduced labor hours by over 40% in some cases.

| Aspect | Manual Handling | Automated Mold Flipping |

|---|---|---|

| Labor Costs | High due to manual labor | Lower due to automation |

| Workplace Safety | Risk of injuries | Enhanced safety |

| Time Efficiency | Slower due to manual effort | Faster with consistent operation |

| Error Rate | Higher due to human error | Minimized with automation |

By comparing traditional methods with automation, one can see that automation ensures consistent quality and reduces errors. Those without automated machines often face higher injury risks and inefficiencies. Our transition to automation at FHOPEPACK demonstrated not just improved safety but a more motivated workforce. Implementing mold flipping machines means prioritizing precision, speed, and employee well-being simultaneously.

Investing in a mold flipper not only transforms operations but also sets a business up for future advancements. My decades in the field have shown that adaptations lead to progress and sustainability. Embracing the power of automation is not a choice anymore; it’s essential.

2. What Are the Cost Savings Associated with Using a Mold Flipper?

Facing increasing demands for efficiency and cost reduction, manufacturers are turning to mold flippers. The automation of mold handling provides a transformative solution, eliminating manual errors and ensuring consistent performance. By adopting mold flipping machines, facilities witness significant labor savings and improved productivity—a winning combination for any business.

Using a mold flipper in your manufacturing process can result in substantial cost savings. Companies experience reduced labor expenses due to automated machinery handling heavy molds, which minimizes manual intervention. Additionally, these machines decrease downtime and enhance operational efficiency, leading to higher profit margins while maintaining quality.

Critically Analyzing Cost Efficiency

When assessing cost savings, we need to look at multiple facets of manufacturing. Here’s a structured analysis:

| Factors | Implementation Impact | Cost Efficiency Outcome |

|---|---|---|

| Labor Costs | Automation reduces manual labor by a significant percentage. | Less workforce, direct cost cuts |

| Production Downtime | Faster mold operations with reduced error rates. | Minimized delays, increased yield |

| Maintenance Expenses | Consistent performance reduces wear and tear and damage. | Lower machine repair costs |

The adoption of a mold flipper involves initial investments. However, the long-term benefits justify this cost. Labor costs drop significantly as less human intervention is needed. Operational efficiency increases as automated systems ensure accuracy and speed. This efficiency translates to a higher output rate, directly impacting revenue. Furthermore, automation minimizes errors and reduces maintenance expenses by preventing human-induced damages. Ultimately, investing in mold flipping machinery aligns with both immediate and future goals of cost efficiency and productivity enhancement. This strategy allows businesses to maintain a competitive edge in the rapidly evolving manufacturing landscape.

3. How to Implement a Mold 180 Degree Turning System in Your Facility?

As the manufacturing sector leans towards efficiency, implementing advanced machinery like the mold 180 degree turning system becomes crucial. Manufacturers face challenges in handling bulky molds manually. Employing such a system not only reduces manual labor but also elevates process efficiency, crucial in meeting industry demands.

To successfully implement a mold 180 degree turning system, start by evaluating your facility’s layout. Consider integrating the system at points where mold turnover frequently occurs. Ensure staff is trained in operational procedures. This approach enhances safety, speeds up process times, and optimizes workflow for maximum productivity.

Key Steps to Implement Mold Turning Systems

Let’s delve into how effectively you can bring automation into your facility:

| Implementation Steps | Description and Expected Outcomes | Benefits Achieved |

|---|---|---|

| Facility Assessment | Analyze current workflow and layout. | Identify strategic implementation areas. |

| Equipment Selection | Choose suitable mold flipping machines based on needs. | Ensure compatibility and effectiveness. |

| Staff Training | Educate staff on machine handling and safety practices. | Enhance operational safety and skill. |

Firstly, a thorough assessment of your facility’s workflow is crucial. Understanding where molds are frequently turned can help pinpoint the best location for your system. This analysis also highlights potential areas for process enhancement. Choosing the right equipment is the next critical step. Machines should meet the specific needs of your operations to ensure seamless integration. Moreover, training the staff is essential. Proper training enhances the safety and effectiveness of the automation process. This aspect not only amplifies speed and precision but also enhances worker safety by minimizing manual handling. By aligning each step with broader operational goals, manufacturers can achieve a streamlined, efficient, and sustainable transition to automated mold turning.

Conclusion

Implementing a mold flipping machine can lead to substantial labor cost reductions and enhanced operational efficiency. By automating critical processes, facilities can achieve higher productivity and maintain a competitive edge in the manufacturing industry. Through strategic integration and adherence to best practices, manufacturers effectively leverage technology to build resilience and advance in a competitive market.