Revolutionizing Tire Handling: An In-Depth Look at Automated Tire Wrapping Machines

Handling and packaging tires, hose reels, tube rolls, and similar bulky, often heavy, circular items presents unique challenges in manufacturing and logistics environments. Manual methods are often slow, inconsistent, and labor-intensive, leading to potential product damage and increased operational costs. The tire wrapping machine, also known as a tyre packing machine or orbital wrapper, emerges as a crucial piece of automation, specifically engineered to address these challenges head-on.

From personal experience in plant upgrades, the transition from manual wrapping (often just palletizing with basic stretch wrap) to a dedicated orbital wrapper can yield immediate, measurable improvements. This article delves into the technical aspects, operational benefits, and practical considerations of implementing this essential equipment, adopting the practical, results-oriented perspective valued by readers of The Fabricator.

1. The Core Problem: Why Manual Tire Packaging Falls Short

Before diving into the solution, let's acknowledge the inefficiencies of traditional methods:

- Inconsistency: Manual wrapping quality varies significantly between operators and even from one shift to the next. This can lead to uneven protection and unstable loads.

- Labor Intensity: Wrapping tires manually, especially larger truck or agricultural tires, is physically demanding and time-consuming, tying up valuable manpower.

- Material Waste: Inconsistent application often results in excessive stretch film usage.

- Product Damage: Insufficient or poorly applied wrapping offers inadequate protection against dust, moisture, UV rays, and abrasion during storage and transport. This impacts product integrity and appearance.

- Throughput Bottlenecks: Manual packaging stations often become the slowest point in an otherwise streamlined production or shipping line.

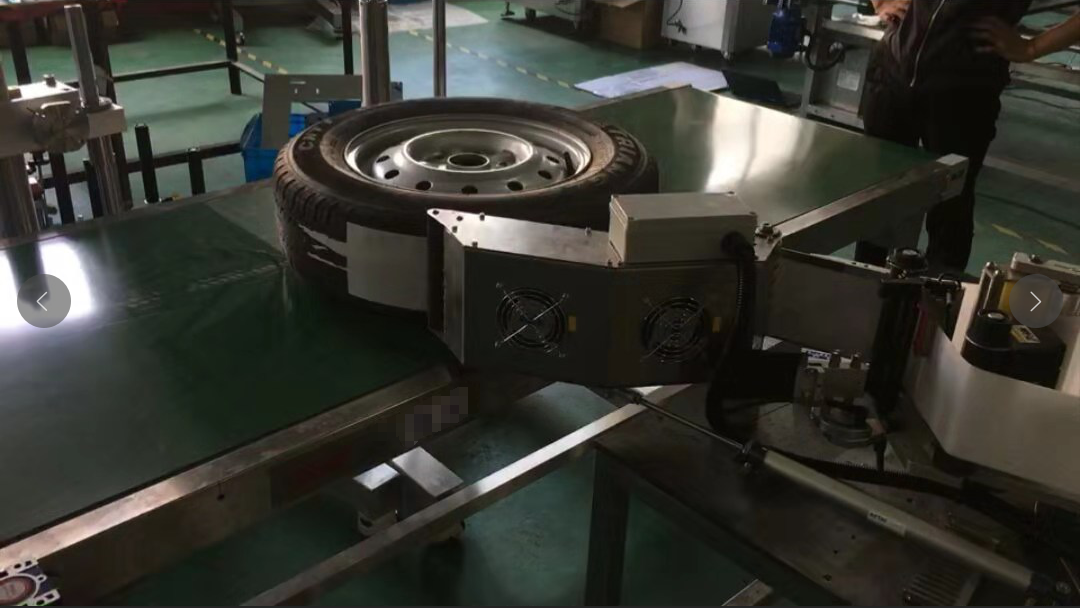

2. The Solution: How Tire Wrapping Machines Operate

At its heart, a tire wrapping machine utilizes the principle of orbital stretch wrapping. Here’s a simplified breakdown of the process:

- Loading: The tire (or similar product) is placed onto the machine's loading area, often integrated with conveyor belts in automated systems.

- Positioning: The tire is moved into the wrapping ring or positioned centrally for the wrapping cycle.

- Wrapping: A rotating ring, carrying a roll of stretch film (or other wrapping material like VCI paper), orbits around and through the center of the tire. Simultaneously, powered rollers often rotate the tire itself. This combined motion ensures complete coverage of the tire's tread and sidewalls.

- Film Application: The film carriage system precisely controls the stretch and overlap of the film, ensuring a tight, secure, and uniform wrap. Tension control is critical for optimal load containment and material usage.

- Cutting and Sealing: Upon cycle completion, the film is automatically cut and typically heat-sealed or wiped down onto the wrapped package, preventing unraveling.

- Unloading: The fully wrapped tire is ejected or conveyed out of the machine.

This automated process guarantees consistency, speed, and optimal material usage cycle after cycle.

3. Key Technical Specifications and Features to Consider

When evaluating tire wrapping equipment, fabricators and plant managers should focus on these parameters:

- Machine Type:

- Horizontal Orbital Wrappers: Most common for tires, allowing easy pass-through integration with conveyors.

- Vertical Orbital Wrappers: Sometimes used for specific applications or larger coils.

- Ring Diameter: Must accommodate the maximum outer diameter (OD) of the tires or products being wrapped. Common ranges cater to car, truck, and even larger OTR (Off-The-Road) tires.

- Maximum Load Capacity: The machine structure and conveyors must handle the weight of the heaviest items.

- Wrapping Speed: Typically measured in rotations per minute (RPM) of the ring or packages per hour. Needs to match or exceed production line requirements.

- Film Carriage System:

- Pre-stretch Ratio: Modern carriages pre-stretch the film (e.g., 200-300%), maximizing yield and wrap strength while minimizing cost. Adjustable pre-stretch is a valuable feature.

- Tension Control: Electronic or mechanical systems ensure consistent film tension throughout the wrap cycle.

- Control System: PLC (Programmable Logic Controller) based systems offer flexibility, allowing for customized wrap programs (e.g., number of wraps, overlap percentage, varying tension) for different product sizes or protection levels. HMI (Human-Machine Interface) touchscreens simplify operation and diagnostics.

- Wrapping Materials: Primarily designed for LLDPE (Linear Low-Density Polyethylene) stretch film, but some models can handle VCI (Volatile Corrosion Inhibitor) film/paper or Kraft paper for specific protection needs.

- Safety Features: Emergency stops, safety fencing or light curtains, interlocked access doors are non-negotiable for operator safety.

- Integration Capabilities: Options for powered infeed/outfeed conveyors, automatic top sheet dispensers, weighing scales, or labeling systems for fully automated lines.

4. Tangible Benefits in the Manufacturing and Logistics Flow

Investing in a tire wrapping machine delivers significant advantages beyond just packaging:

- Enhanced Product Protection: Provides a robust barrier against:

- Dust and Dirt: Keeps tires clean during storage and transit.

- Moisture and Humidity: Prevents water damage and potential mold growth.

- UV Degradation: Protects rubber compounds from sunlight exposure.

- Abrasion and Scuffing: Reduces damage during handling and shipping.

- Rustproofing (with VCI): Essential if wrapping metal wheels or components alongside tires.

- Drastic Labor Savings: Automating the wrapping process frees up personnel for more value-added tasks, directly reducing labor costs associated with packaging. We've seen operations reassign one or even two full-time employees per shift after implementation.

- Improved Operational Efficiency: Significantly increases throughput compared to manual methods. Consistent cycle times allow for better production planning and scheduling.

- Material Cost Reduction: Precise control over film stretch and overlap minimizes waste, often leading to a 30-50% reduction in film consumption compared to manual wrapping.

- Optimized Warehouse Space: Tightly wrapped tires can sometimes be stored more densely or stacked more securely (depending on the tire type and wrap quality).

- Professional Product Presentation: A neat, uniform wrap enhances the perceived quality of the product and reinforces brand image upon delivery.

- Enhanced Safety: Reduces manual handling of heavy/awkward items and eliminates repetitive motions associated with manual wrapping, contributing to a safer workplace.

5. Personal Insights: Selecting the Right Machine and Avoiding Pitfalls

Choosing the right machine involves more than just matching basic specs. Consider these points based on real-world deployment:

- Future-Proofing: Consider potential changes in tire sizes or production volume. Opting for a machine with slightly larger capacity or higher speed might offer better long-term ROI.

- Integration is Key: How will the machine fit into your existing workflow? Assess conveyor heights, line speed synchronization, and control system handshakes if integrating into an automated line. Poor integration can negate efficiency gains.

- Film Quality Matters: Don't skimp on stretch film. Low-quality film can break frequently, causing downtime, and may not provide adequate protection or load containment, even with a good machine. Work with reputable suppliers.

- Operator Training: While automated, proper operation, loading, film roll changes, and basic troubleshooting require trained personnel. Ensure adequate training is provided.

- Maintenance Access: Look for designs that allow easy access for routine maintenance like cleaning sensors, lubricating bearings, and changing wear parts on the film carriage. Downtime for maintenance is inevitable, but minimizing it is crucial.

6. Beyond Basic Wrapping: Integration and Advanced Options

For high-volume operations, tire wrapping machines are often just one component of a larger automated system. Consider potential integrations:

- Conveyor Systems: Power roller, belt, or chain conveyors for seamless movement into and out of the wrapper.

- Robotic Handling: Robots can be used for loading tires onto the infeed conveyor or for palletizing wrapped tires.

- Data Logging & Connectivity: Modern PLCs can provide data on cycle counts, film usage, and machine status, enabling better monitoring and predictive maintenance.

7. Material Choices for Specific Needs

While standard LLDPE stretch film is the workhorse, alternatives exist:

- VCI Film/Paper: Impregnated with volatile corrosion inhibitors, essential if wrapping tires mounted on steel or aluminum rims to prevent rust or oxidation.

- UV-Inhibitor Film: Offers enhanced protection for long-term outdoor storage.

- Colored/Opaque Film: Can be used for branding, product differentiation, or concealing high-value items.

8. Maintenance for Longevity and Performance

Like any industrial equipment, regular maintenance is vital:

- Daily Checks: Inspect for film remnants, check sensor cleanliness, listen for unusual noises.

- Weekly/Monthly: Clean rollers and guides, check belt/chain tension, inspect film carriage components.

- As Recommended: Follow manufacturer guidelines for lubrication and replacement of wear parts (e.g., cutting blades, gripper pads).

Conclusion: A Smart Investment for Modern Operations

The automated tire wrapping machine is far more than just a packaging device. It's a strategic investment that directly impacts operational efficiency, product quality, labor costs, and workplace safety. By providing consistent, high-quality protection tailored to the unique shape of tires and similar products, this equipment streamlines a critical process in the manufacturing and distribution chain. For fabricators and manufacturers dealing with tires, hoses, or coils, evaluating and implementing the right tire wrapping solution offers a clear path to enhanced productivity and profitability.

For inquiries or specific application discussions:

info@fhopepack.com

Learn more about specific machine models:

https://www.fhopepack.com/Tyre-packing-machine/