Streamlining Heavy Coil Logistics: The Advanced Roller Station for Steel Sheet Covering and Strapping

Handling and packaging large, heavy coils—whether steel, wire, or other materials—presents significant logistical challenges. Ensuring product integrity during transit and storage while maintaining operational efficiency requires robust, specialized solutions. The roller station designed for big coil packing with steel sheet covering and strapping stands out as a critical asset in modern industrial environments.

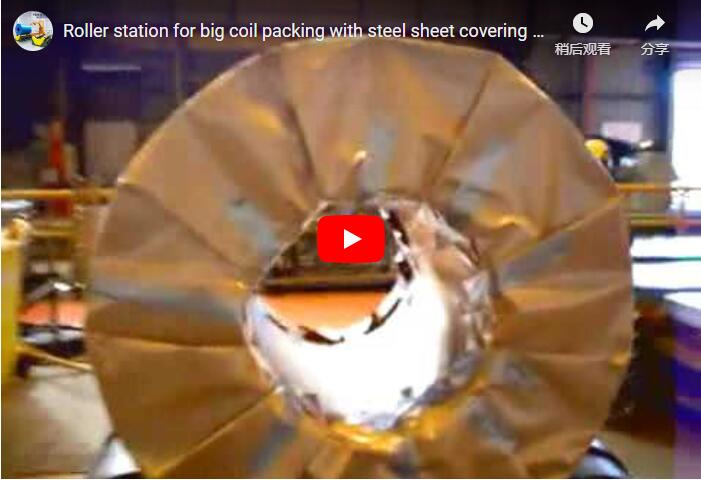

(Remember to add descriptive alt text to any images in your post for accessibility and SEO, e.g., "Automated roller station securely strapping a steel coil covered with protective steel sheet.")

1. The Challenge: Protecting High-Value Coils

Large coils are inherently difficult to manage due to their weight, size, and potential for damage (corrosion, deformation). Manual or semi-manual packing processes can be:

- Time-consuming: Slowing down the entire production or shipping line.

- Labor-intensive: Requiring significant manpower.

- Inconsistent: Leading to variations in package quality and protection levels.

- Risky: Posing safety hazards to personnel during handling and strapping.

Effective packaging is not just about containment; it's about preserving the value of the material within.

2. The Solution: Automated Roller Station Technology

An automated roller station addresses these challenges head-on. It's essentially an integrated packaging system featuring:

- Powered Roller Conveyors: Heavy-duty rollers designed to support and smoothly transport massive coils through the packaging sequence.

- Steel Sheet Covering Unit: Automatically dispenses and applies a protective steel sheet layer around the coil's circumference or over its eye, shielding it from environmental factors and handling impacts.

- Automated Strapping Head(s): Applies high-tensile steel or PET strapping at predetermined positions with consistent tension, securing the steel sheet cover and unitizing the coil package.

3. Operational Workflow: A Seamless Process

Witnessing one of these stations in action highlights its efficiency. The typical automated process unfolds as follows:

- Coil Loading: The coil is placed onto the entry section of the roller conveyor, often via crane or forklift.

- Positioning: The rollers automatically rotate and center the coil for the covering and strapping stages. Sensors ensure precise alignment.

- Steel Sheet Application: The covering unit dispenses the pre-cut or continuously fed steel sheet, wrapping it around the coil as it rotates.

- Strapping: The strapping head(s) move into position and apply straps circumferentially or through the coil eye, tensioning and sealing them securely.

- Discharge: The fully packed and secured coil is conveyed off the station, ready for storage or shipment.

4. Key Technical Features and Considerations

When evaluating or understanding these systems, key parameters include:

- Coil Handling Capacity:

- Maximum Coil Weight (e.g., 5 - 30 tons)

- Coil Outer Diameter Range (e.g., 800mm - 2200mm)

- Coil Width Range (e.g., 500mm - 2000mm)

- Roller Specifications:

- Roller Material (e.g., Heavy-duty steel, PU coated)

- Drive System (e.g., Chain-driven, motorized rollers)

- Conveying Speed (Variable or fixed)

- Covering System:

- Sheet Material Compatibility (e.g., Galvanized steel, Stainless steel)

- Sheet Thickness Range

- Application Method (e.g., Circumferential wrap, Eye-covering)

- Strapping System:

- Strap Type (Steel or PET)

- Strap Dimensions (Width, Thickness)

- Number and Position of Straps (Programmable)

- Tensioning Force (Adjustable)

- Control System: PLC-based automation with HMI (Human-Machine Interface) for operation and diagnostics.

5. Strategic Advantages: Efficiency, Safety, and Quality

Investing in an automated roller packing station delivers tangible benefits:

- Enhanced Efficiency: Dramatically reduces packing cycle times compared to manual methods, increasing overall throughput.

- Improved Safety: Minimizes manual handling of heavy coils and strapping operations, significantly reducing injury risks.

- Consistent Package Quality: Ensures every coil is packed to the same high standard, with uniform covering and secure strapping.

- Superior Product Protection: The steel sheet provides robust protection against moisture, dust, and physical damage during handling, transport (road, rail, sea), and storage. From personal observation in facilities that adopted this, the reduction in damage claims related to transit abrasion or water ingress is often substantial.

- Labor Optimization: Frees up personnel for higher-value tasks.

- Reduced Material Waste: Automated systems often optimize the use of covering and strapping materials.

6. Industry Applications

These roller stations are indispensable in sectors dealing with large coils, including:

- Steel Mills and Service Centers

- Aluminum Coil Producers

- Copper and Brass Mills

- Wire and Cable Manufacturers

- Paper Mills (for large paper rolls)

7. Integration and Customization

Modern roller stations are designed for integration into existing production lines, often working in conjunction with coil cars, tilters, weighing systems, and marking/labeling units. They can be customized based on specific coil dimensions, required throughput speeds, and the level of automation desired.

Conclusion: A Cornerstone of Modern Coil Logistics

The roller station for big coil packing with steel sheet covering and strapping is more than just a machine; it's a strategic investment in efficiency, safety, and product quality assurance. By automating this critical step in the logistics chain, businesses can protect their valuable products, optimize workflows, and maintain a competitive edge in demanding industrial markets.

For more detailed information on coil packing solutions tailored to specific needs:

https://www.fhopepack.com/Coil_packing_machine.html

For inquiries, please contact: info@fhopepack.com