Streamlining Operations: A Deep Dive into the FHOPE PVC Hose Packing & Flex Pipe Wrapping Machine

In today's fast-paced manufacturing and distribution environments, efficiency and product protection are paramount. Manually packing coils of PVC hoses, flexible pipes, and similar materials can be time-consuming, labor-intensive, and often results in inconsistent packaging quality. This is where automated solutions become essential. The FHOPE PVC hose packing machine, also commonly referred to as a flex pipe wrapping machine, offers a robust and efficient answer to these challenges.

Let's delve deeper into why this machine is becoming a cornerstone for businesses handling coiled products.

1. The Challenge: Manual Coil Packaging Inefficiencies

Before exploring the solution, it's crucial to understand the bottlenecks of traditional manual wrapping:

- High Labor Costs: Manual wrapping requires significant personnel time, directly impacting operational expenses.

- Inconsistent Quality: Achieving uniform tension and coverage manually is difficult, potentially leading to loose packages or product damage.

- Slow Throughput: Manual processes inherently limit the number of coils that can be packaged per shift.

- Risk of Damage: Improperly secured coils are more susceptible to damage during handling, storage, and transit.

2. The FHOPE Solution: Automated PVC Hose & Flex Pipe Wrapping

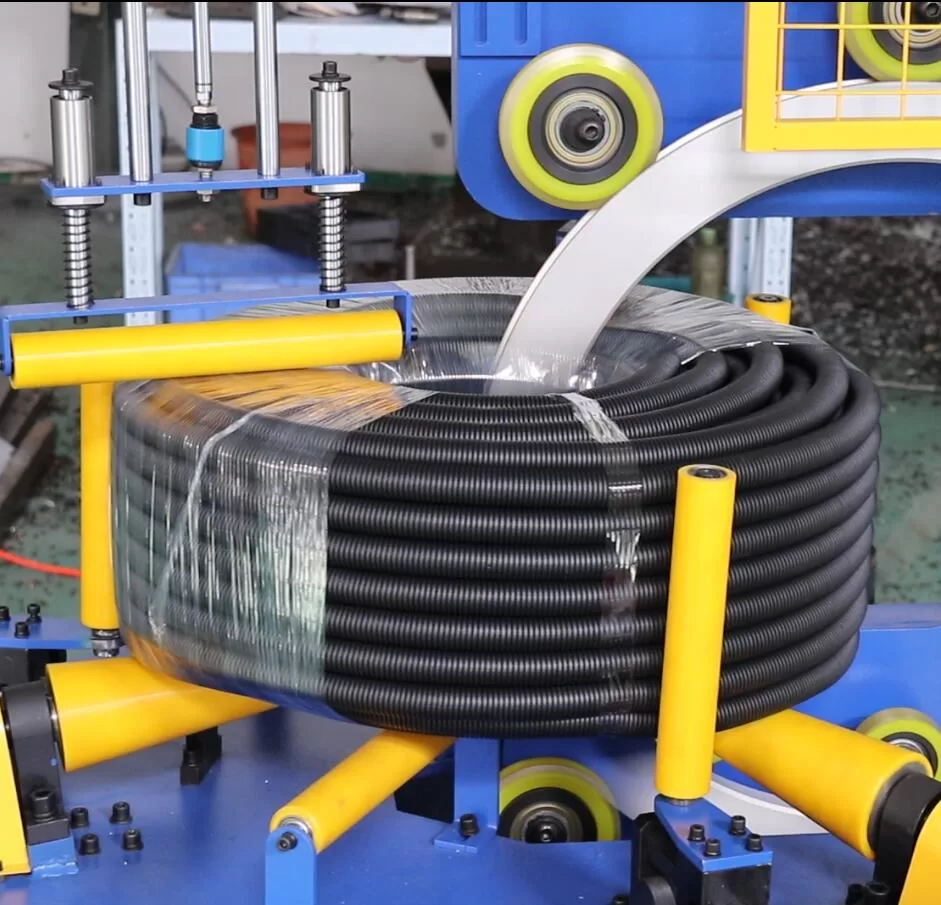

The FHOPE machine tackles these issues head-on. It's specifically engineered to automate the process of wrapping PVC hose coils, flexible pipes, corrugated pipes, and other coiled materials using stretch film. The core function involves rotating the coil while simultaneously dispensing and applying stretch film around its circumference, creating a tight, secure, and protective package.

3. Technical Specifications & Operational Insight

Understanding the machine's capabilities requires a look at its typical specifications (Note: Specific models may vary, always confirm details for your exact requirements):

- Wrapping Material: Primarily LLDPE Stretch Film

- Coil Size Compatibility:

- Inner Diameter (ID): Typically adjustable range, e.g., 150-500mm

- Outer Diameter (OD): Typically adjustable range, e.g., 300-800mm

- Coil Width/Height: Typically adjustable range, e.g., 50-300mm

- Wrapping Efficiency: Variable, often in the range of 20-40 seconds per coil (depending on size and wrapping layers)

- Control System: Usually PLC (Programmable Logic Controller) based with an HMI (Human-Machine Interface) touch screen for easy operation and parameter adjustment.

- Key Adjustments:

- Wrapping Tension Control

- Film Overlap Rate

- Rotation Speed

- Wrapping Cycle Settings

- Operation: Semi-automatic typically involves manual loading/unloading, while fully automatic lines can integrate conveyors.

The process is generally straightforward: an operator places the hose coil onto the machine's designated area (often rollers). The wrapping cycle is initiated via the HMI or a footswitch. The machine then automatically applies the stretch film according to the pre-set parameters, cuts the film upon completion, and the securely wrapped coil is ready for removal.

4. Key Advantages Driving Value

The benefits outlined initially become much clearer with this technical context:

- Enhanced Efficiency & Speed: Automation drastically reduces wrapping time per coil compared to manual methods, significantly boosting throughput. Reducing manual handling directly translates to lower labor requirements.

- Superior Product Protection: The consistent application of stretch film creates a tight cocoon around the coil. This shields the product from dust, moisture, scratches, and minor impacts during storage and shipping. The secure wrap also prevents coils from unwinding or tangling.

- Unmatched Consistency: Automated control ensures every coil is wrapped with the same tension and film overlap, leading to uniform package quality and appearance – crucial for brand presentation.

- Operational Flexibility: The ability to adjust parameters like tension, speed, and overlap allows the machine to handle a diverse range of coil dimensions and weights effectively, making it versatile across different product lines.

- Cost-Effectiveness: Beyond labor savings, the optimized use of stretch film (consistent overlap, appropriate tension) can reduce material consumption compared to inconsistent manual wrapping. Furthermore, reduced product damage translates to fewer returns and replacements.

5. Our Perspective: Reliability in Action

From our experience and feedback within the industry, the FHOPE PVC hose packing machine stands out for its reliability and user-friendly design. The PLC and HMI interface simplifies setup and operation, requiring minimal training. Its robust construction ensures durability in demanding industrial environments. When evaluating packaging solutions, consistency and dependability are non-negotiable, and this machine consistently delivers on both fronts.

6. Is This the Right Fit for Your Operation?

This machine is an ideal investment for:

- Manufacturers of PVC hoses, hydraulic hoses, wires, cables, and various types of flexible tubing.

- Distribution Centers and Logistics Providers handling large volumes of coiled products.

- Businesses seeking to reduce packaging labor costs, improve package quality, and increase overall operational efficiency.

Consider your current packaging volume, labor costs associated with manual wrapping, and the value of enhanced product protection when evaluating the potential ROI.

Conclusion: Elevating Your Packaging Standards

The FHOPE PVC hose packing machine and flex pipe wrapping machine represents more than just automation; it's a strategic tool for enhancing operational efficiency, ensuring product integrity, and achieving consistent packaging quality. By automating a critical but often overlooked process, businesses can reallocate labor resources, reduce material waste, minimize damage, and ultimately deliver a better-protected product to their customers. It's a cost-effective and reliable solution for any operation serious about optimizing its coil packaging workflow.

For more detailed information and specifications tailored to your needs:

https://www.fhopepack.com/Hose-packaging-machine/

Contact us: info@fhopepack.com