In today's fast-paced manufacturing landscape, efficiency and precision in cable handling are paramount. Manual coiling and wrapping processes often introduce bottlenecks, inconsistencies, and potential damage to sensitive cables. The Online Automatic Cable Coiling and Wrapping Machine addresses these challenges head-on, offering a robust, automated solution designed for seamless integration into modern production lines. This article delves into the technical specifications, design considerations, operational benefits, and real-world applications of this essential equipment, providing valuable insights for fabricators and manufacturers seeking to optimize their cable packaging operations.

1. Enhancing Production Flow: The Role of Automated Coiling & Wrapping

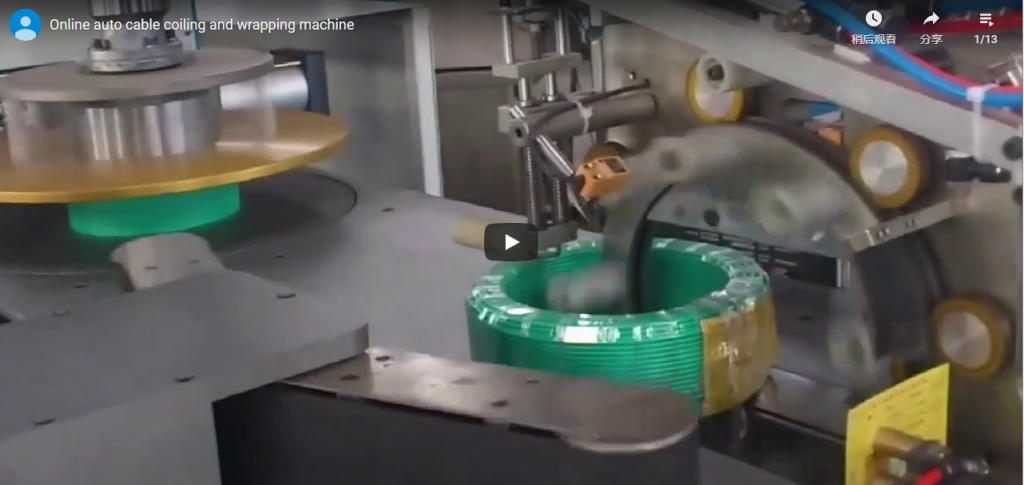

The primary function of an online automatic cable coiling and wrapping machine is to streamline the transition from raw cable extrusion or processing to a packaged, ready-for-shipment state. By automating both the coiling and wrapping stages, this integrated unit significantly reduces manual labor requirements, minimizes handling errors, and boosts overall throughput. Its design philosophy centers on reliability, speed, and adaptability to various cable types and production demands.

2. Dissecting the Machine: Design, Structure, and Key Components

Understanding the core components provides insight into the machine's capabilities and operational advantages:

- Robust Frame and Structure: Typically constructed from heavy-gauge steel, the machine frame ensures stability and vibration damping, critical for maintaining coiling precision at high speeds. The design often prioritizes a compact footprint while allowing easy access for maintenance.

- Precision Coiling Mechanism: Driven by servo motors or precisely controlled variable frequency drives (VFDs), the coiling head ensures consistent coil diameters and neat layering. Advanced systems incorporate tension control mechanisms to prevent cable stretching or damage, particularly crucial for delicate fiber optic or data cables.

- Accurate Traversing Unit: Synchronized with the coiling head, the traversing system guides the cable accurately across the coiling formers. This ensures level winding, resulting in stable, uniform coils that are easier to handle and less prone to tangling. Programmable traverse widths accommodate different cable diameters and desired coil widths.

- Automated Wrapping System: Following coiling, the package is automatically transferred to the wrapping station. This unit typically uses stretch film (PE, LLDPE) or sometimes PVC tape, applying it securely around the coil. Key parameters like wrapping overlap, tension, and the number of layers are programmable, ensuring optimal protection and package integrity based on cable type and shipping requirements. Cutter and clamp mechanisms automate the start and finish of the wrap cycle.

- Advanced Control System (PLC & HMI): The brain of the machine is its Programmable Logic Controller (PLC), coupled with a Human-Machine Interface (HMI), usually a touchscreen panel. This allows operators to:

- Set and store recipes for different cable types (diameter, coil length, inner/outer diameter, wrapping parameters).

- Monitor the process in real-time.

- Receive diagnostic information and alerts.

- Integrate the machine with upstream and downstream equipment or factory Manufacturing Execution Systems (MES).

3. Key Technical Specifications Overview

While specific configurations vary, typical technical parameters provide a baseline understanding. Note: The specifications listed below are representative and may not perfectly match the machine shown in the video. Always consult with the manufacturer for precise details corresponding to a specific model.

- Machine Type: Fully Automated Online Cable Coiling and Wrapping Machine

- Automation Level: High (Automatic feeding synchronisation, coiling, cutting, wrapping, and ejection)

- Performance:

- Coiling Speed: Variable, potentially reaching up to 1200 meters/hour depending on cable size and coil dimensions.

- Cable Diameter Range: Typically accommodates cables from approx. 2mm up to 20mm (Model specific).

- Configuration:

- Coil Inner Diameter (ID): Adjustable, common ranges include 100mm to 300mm.

- Maximum Coil Outer Diameter (OD): Up to 800mm (Model specific).

- Maximum Coil Width: Adjustable based on traversing settings.

- Wrapping Material: Compatible with PE stretch film, PVC film, or other specified materials.

- Control & Power:

- Control System: Industrial PLC with Touchscreen HMI (e.g., Siemens, Allen-Bradley, Mitsubishi).

- Power Requirement: Typically 230V/400V, 50/60Hz, 3-phase (Verify based on region and model).

- Physical:

- Approx. Machine Dimensions (L x W x H): e.g., 3500mm x 1500mm x 1700mm (Varies significantly by model and configuration).

4. From the Shop Floor: Operational Efficiency and User Experience

Beyond the technical data, the practical advantages are significant:

- Reduced Labor Costs: Automation drastically cuts down the manual effort needed for coiling and wrapping.

- Improved Consistency: Machine precision ensures every coil meets predefined specifications for length, diameter, and wrap quality, enhancing product professionalism.

- Increased Throughput: Continuous, high-speed operation significantly outpaces manual methods, aligning packaging speed with production output.

- Enhanced Safety: Enclosed moving parts and automated sequences reduce operator exposure to potential hazards associated with manual coiling and cutting.

- Material Savings: Optimized wrapping programs use stretch film efficiently, minimizing waste compared to manual wrapping.

- User-Friendliness: Modern HMIs offer intuitive interfaces for setup, operation, and troubleshooting. Operators often report quick learning curves and appreciate the ability to save and recall settings for recurring jobs, minimizing changeover times.

automatic cable coiling2 5. Diverse Applications Across Industries

The versatility of the online auto cable coiling and wrapping machine makes it indispensable in various sectors:

- Telecommunications: Essential for packaging delicate optical fiber cables, coaxial cables, and data communication cables (e.g., CAT5e, CAT6). Precise tension control and secure wrapping protect signal integrity.

- Electrical Power & Distribution: Efficiently coils and wraps building wires (THHN, Romex®), industrial power cables, and control cables, preparing them for contractors and distributors. Handles larger diameters and ensures robust packaging for rough handling.

- Automotive: Used by manufacturers of automotive wire harnesses and battery cables. Consistent coiling aids in subsequent automated assembly processes, and secure wrapping protects cables during transit within the supply chain.

- Appliance Manufacturing: Coiling power cords and internal wiring for household and industrial appliances.

- Construction: Packaging various types of electrical and communication cables used in building projects.

6. Conclusion: A Strategic Investment in Cable Packaging

The Online Automatic Cable Coiling and Wrapping Machine represents a significant step forward from manual or semi-automatic processes. Its integration into a production line yields tangible benefits in productivity, consistency, safety, and cost-efficiency. For fabricators handling significant volumes of cable, investing in this technology provides a competitive edge by ensuring high-quality, professionally packaged products ready for market demands. The precision engineering, robust construction, and advanced control systems characteristic of these machines deliver reliable performance and a strong return on investment for demanding industrial environments.

For more information or specific configuration details, please contact:

www.fhopepack.com

coiler@fhopepack.com