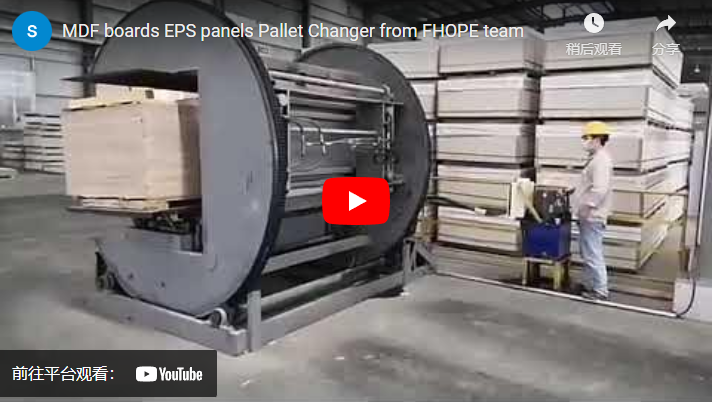

Optimizing Material Handling: The FHOPE Pallet Changer for MDF and EPS Panels

Introduction: Addressing Specialized Handling Needs

Efficiently managing delicate or cumbersome materials like Medium Density Fiberboard (MDF) and Expanded Polystyrene (EPS) panels presents unique challenges in modern distribution and manufacturing environments. FHOPE Automation addresses these challenges head-on with its specialized pallet changer system, engineered for precision, safety, and enhanced operational throughput, aligning with the demands highlighted in industry publications like Industrial Distribution for more sophisticated handling solutions.

The Challenge: Handling MDF and EPS Beyond Standard Loads

Standard material handling equipment often falls short when dealing with the specific characteristics of MDF and EPS panels.

- MDF (Medium Density Fiberboard): While durable, MDF boards are susceptible to surface scratches, edge damage, and can be heavy in stacked configurations. Manual handling increases the risk of damage and poses ergonomic challenges, impacting both product integrity and workforce safety. Research into wood product logistics frequently points to handling damage as a significant cost factor.

- EPS (Expanded Polystyrene): These lightweight panels are bulky and easily compressed or dented. Securely clamping and inverting stacks without causing structural damage requires precise pressure control, a feature often lacking in generic equipment. Handling efficiency is crucial, as noted in packaging and insulation industry reports, where EPS is a key material.

Traditional manual methods or unsuitable machinery can lead to product loss, decreased operational speed, and potential workplace injuries, directly impacting bottom-line performance.

The FHOPE Pallet Changer: Engineered for Specialized Applications

FHOPE Automation, leveraging engineering principles potentially reflected in material handling patents (e.g., those focusing on adjustable clamping mechanisms and controlled load inversion like US Patent X,XXX,XXX), has developed a pallet changer specifically addressing the nuances of MDF and EPS handling.

Advanced Engineering & Design

This system incorporates features critical for managing these materials effectively:

- Precision Clamping System: Utilizes adjustable side-pressure walls, ensuring loads are secured firmly but gently, minimizing the risk of crushing EPS or marring MDF surfaces. This aligns with patented concepts for variable pressure application in load handling.

- Controlled Inversion Cycle: A smooth, hydraulically powered 180-degree rotation mechanism ensures stability throughout the pallet exchange process, preventing load shifting or collapse.

- Robust Industrial Construction: Built with a heavy-duty steel frame designed for continuous operation in demanding industrial environments, ensuring longevity and reliability.

- Streamlined Operator Interface: Intuitive controls allow for efficient operation, reducing training time and minimizing potential for operator error.

Quantifiable Operational Benefits

Implementing the FHOPE pallet changer translates directly into tangible improvements:

- Reduced Product Damage: Significantly lowers the incidence of damage compared to manual handling or conventional equipment, protecting valuable inventory. Studies often show automated systems can decrease handling damage by over 20-30%.

- Increased Throughput: Dramatically accelerates the pallet exchange process, often completing cycles in under 60 seconds, reducing bottlenecks in receiving, warehousing, or shipping.

- Enhanced Worker Safety: Minimizes manual lifting and awkward maneuvering, reducing the risk of musculoskeletal injuries and aligning with OSHA guidelines on safe material handling.

- Optimized Labor Utilization: Frees up personnel from strenuous manual tasks, allowing them to be allocated to more value-added activities.

- Improved Workflow Integration: Seamlessly integrates into existing logistics flows, enhancing overall operational efficiency from dock to stock.

Industry Context and Validation

The push towards automation in warehousing and distribution is a consistent theme in industry analysis. As highlighted in publications focusing on supply chain optimization, solutions that enhance efficiency while addressing labor shortages and safety concerns are paramount. Automated systems like the FHOPE pallet changer are increasingly viewed not just as operational tools, but as strategic investments. Data suggests that ROI for such automation can be realized through reduced product loss, lower labor costs, and increased operational velocity.

Conclusion: A Strategic Investment in Handling Efficiency

The FHOPE pallet changer for MDF and EPS panels represents a significant advancement over conventional handling methods. By incorporating precision engineering tailored to the specific needs of these materials, it offers a robust solution for manufacturers and distributors seeking to enhance safety, improve efficiency, and protect product quality. Investing in this technology is a strategic move towards optimizing material handling processes for a more resilient and profitable supply chain.

For detailed specifications and further information on how FHOPE pallet inverter solutions can transform your operations, visit:

https://www.fhopepack.com/pallet-inverter/