Optimizing Efficiency: Selecting the Ideal Automated Packing Line for Steel Cable and Wire Coils

In high-volume manufacturing and distribution environments, particularly within the steel cable and wire industry, efficient packaging is paramount. Manual or semi-automated processes often struggle to keep pace with production output, leading to bottlenecks, increased labor costs, and potential inconsistencies in package quality. Transitioning to a fully automated packing line, such as the integrated coiling and strapping solutions offered by FHOPE, presents a significant opportunity to enhance throughput, ensure product integrity, and achieve substantial operational savings. This article delves into the critical factors involved in selecting the right automated packing line, focusing on technical specifications, design considerations, and real-world performance benefits.

1. Understanding the Need: Challenges in Manual Cable Coil Handling

Traditional methods of coiling, strapping, and handling heavy steel cable or wire coils often involve significant manual labor. This approach presents several inherent challenges:

- Labor Intensity: Manual handling is physically demanding and requires substantial manpower, contributing significantly to operational costs.

- Inconsistent Quality: Manual coiling and strapping can lead to variations in coil dimensions, tightness, and strap placement, potentially affecting product protection and handling downstream.

- Safety Risks: Handling heavy coils poses ergonomic risks and potential for workplace injuries.

- Speed Limitations: Manual processes inevitably limit the overall packaging throughput, creating bottlenecks that can stifle production capacity.

- Product Damage: Improper handling can lead to damage to the cable or wire itself.

Addressing these challenges necessitates a move towards automation, streamlining the process from end-of-production to final dispatch.

2. Core Components of an Automated Steel Cable/Wire Packing Line

A comprehensive automated packing line integrates several key modules working in unison. Understanding these components is crucial for selecting a system that matches specific operational needs:

- Pay-Off Station: Manages the feeding of wire or cable from the production source (e.g., extruder, drawing machine, or storage reels) into the coiling unit, often incorporating tension control.

- Automatic Coiling Unit: Precisely winds the cable or wire into coils of predetermined lengths and diameters. Key features include accurate length measurement (encoder-based), programmable coil dimensions, and smooth traversing mechanisms for level winding.

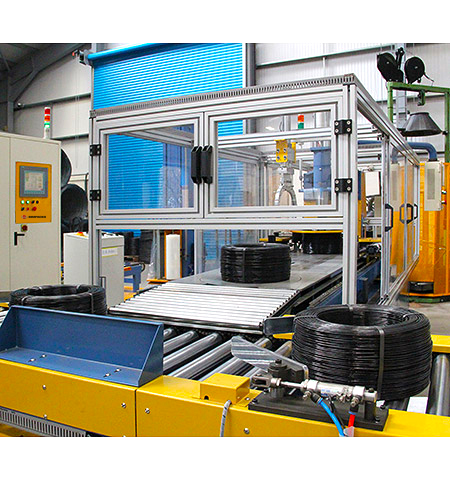

- Coil Handling & Transfer: Automated systems (conveyors, robotic arms) transport the finished coil from the coiler to subsequent stations.

- Automatic Strapping Unit: Secures the coil using materials like Polypropylene (PP) or Polyester (PET) strapping. Important considerations include the number of straps per coil (typically 2-4), strap tension control, and the type of sealing mechanism (e.g., heat seal, friction weld). FHOPE offers specialized solutions like this automatic coiling and strapping machine packing line.

- Optional Wrapping Unit: Applies stretch film or shrink wrap around the strapped coil for enhanced protection against environmental factors (dust, moisture) and improved load stability.

- Stacking & Palletizing Unit: Automatically stacks finished coils onto pallets, often utilizing robotic arms for precision and efficiency, preparing them for warehousing or shipping.

- Control System (PLC & HMI): The central brain of the line, typically using a Programmable Logic Controller (PLC) and a Human-Machine Interface (HMI) for setting parameters, monitoring operations, diagnostics, and potential integration with plant-wide Manufacturing Execution Systems (MES).

3. Design Considerations for Optimal Performance

Selecting an automated line requires careful consideration of various design and operational factors:

- Throughput Requirements: Define the necessary output in coils per hour or shift to match production capacity. High-speed lines are essential for large-scale operations.

- Cable/Wire Specifications: The system must accommodate the range of product types, including diameter, material (steel, copper, fiber optic), flexibility, and required coil dimensions (Inner Diameter - ID, Outer Diameter - OD, Width/Height).

- Coil Weight: Ensure all handling components (coiler, conveyors, strapping head, robot) are rated for the maximum expected coil weight.

- Strapping Requirements: Specify the type of strap, number of straps per coil, required tension, and desired strap positions.

- Level of Automation: Determine the scope – coiling and strapping only, or a fully integrated line including wrapping and robotic palletizing.

- Flexibility and Changeover: Consider how easily the line can be adjusted to handle different product types or coil sizes, minimizing downtime during changeovers.

- Footprint and Layout: Evaluate available floor space and ensure the line configuration fits efficiently within the facility.

- Integration Capabilities: Assess the need to integrate the packing line controller with upstream production machinery and downstream inventory management systems.

- Safety Standards: Ensure the equipment complies with relevant safety regulations (e.g., ISO, CE), incorporating necessary guarding, interlocks, and emergency stop systems.

4. Technical Data & Performance Benchmarks (Illustrative Example)

When evaluating different automated packing lines, comparing key technical specifications is vital. Below are typical parameter ranges to consider:

- Parameter | Typical Specification Range

- ---|---

- Applicable Product Diameter: | 5mm - 50mm (Varies significantly based on machine model)

- Max. Coiling Speed: | 100 - 300 meters/minute

- Coil Outer Diameter (OD): | 300mm - 1200mm

- Coil Inner Diameter (ID): | 150mm - 800mm

- Coil Width/Height: | 50mm - 600mm

- Max. Coil Weight: | 50kg - 500kg+

- Strapping Material: | PP / PET Strap

- Strap Width: | 9mm - 19mm

- Strapping Cycle Time: | 15 - 40 seconds per coil (depending on number of straps)

- Wrapping Cycle Time (if applicable): | 30 - 60 seconds per coil

- Stacking Height (if applicable): | Up to 2000mm

- Control System: | PLC (e.g., Siemens, Allen-Bradley) + Touchscreen HMI

- Power Requirements: | 380V/50Hz/3Ph (or customized)

- Air Pressure: | 0.5 - 0.7 MPa

Note: These are general ranges. Specific values depend heavily on the machine model and configuration.

5. FHOPE's Automated Packing Solution: A Closer Look

FHOPE has developed advanced automation systems specifically tailored for the challenges of steel wire and cable wire packaging. Their lines often feature:

- High-Speed Operation: Designed to keep pace with demanding production schedules.

- Integrated Functionality: Combining coiling, precise strapping, optional shrink wrapping, and robotic stacking into a seamless workflow.

- Labor Optimization: As highlighted, enabling scenarios where a single operator can potentially oversee multiple lines (e.g., 5-8 lines), drastically reducing labor costs per unit.

- Reliability and Durability: Built for industrial environments, focusing on robust construction and dependable components.

- Customization: Offering tailored solutions based on specific client requirements regarding coil sizes, weights, and desired automation levels. Explore various options within FHOPE's cable winder solutions.

The investment in such an automated system aims to deliver rapid ROI through increased efficiency, reduced labor, improved package quality, and enhanced safety, automating the critical path from production completion to palletized, ready-to-ship coils.

6. Implementation & User Experience

Beyond technical specifications, consider the practical aspects of adopting an automated line:

- Installation & Commissioning: Understand the supplier's support during setup and startup.

- Operator Training: Ensure comprehensive training is provided for operation, basic troubleshooting, and parameter adjustments via the HMI.

- Maintenance Requirements: Review the recommended preventative maintenance schedule to ensure long-term reliability and minimize unplanned downtime.

- Ease of Use: Evaluate the HMI's intuitiveness and the overall user-friendliness of the system for daily operation and changeovers.

- Supplier Support: Consider the availability of technical support, spare parts, and service from the manufacturer (like FHOPE).

Users often report significant improvements in operational flow, reduced physical strain on workers, consistent package appearance, and better inventory management upon implementing such automated systems.

7. Choosing the Right Configuration: Key Questions to Ask

To ensure you select the most suitable automated packing line, ask potential suppliers and your internal team these critical questions:

- What is our current and projected production volume (coils per day/shift)?

- What are the exact physical specifications (diameter, material, ID, OD, width, weight) of all cable/wire types we need to pack?

- What level of automation is required? (Coiling + Strapping? Add Wrapping? Add Palletizing?)

- What are our specific strapping requirements (material, number, tension)?

- How important is flexibility for handling future product variations or sizes?

- What are our facility's space constraints and layout considerations?

- Do we need integration with existing plant control systems (MES/ERP)?

- What is our budget, and what is the expected Return on Investment (ROI) based on labor savings and efficiency gains?

Conclusion: Automating for Competitive Advantage

Choosing the right automatic packing line for steel cable and wire coils is a strategic decision that directly impacts operational efficiency, cost-effectiveness, and product quality. By carefully analyzing requirements, understanding core components, evaluating technical data, and considering design factors and user experience, manufacturers can select a system that delivers significant benefits. Solutions like those offered by FHOPE provide a pathway to streamline operations, reduce manual labor dependency, enhance safety, and ultimately strengthen competitive positioning in the demanding cable and wire market. Investing in the right automation is investing in future productivity and growth.