Technical Review: Boosting Packaging Efficiency with the Automated Wire Coil Wrapping Machine

In today's demanding industrial landscape, safeguarding valuable coiled products like steel wire, copper tubing, and cables during transit and storage is paramount. Manual or semi-automated packaging methods often fall short, leading to inconsistencies, potential product damage, and higher labor costs. The automated wire coil wrapping machine emerges as a robust solution, engineered to deliver consistent, high-quality protective wrapping for a diverse range of coil specifications. This review delves into the technical capabilities, operational advantages, and practical benefits observed when implementing this essential piece of packaging equipment.

1. Core Capabilities: Versatility in Materials and Coil Handling

A key strength of the modern wire coil wrapping machine lies in its adaptability. It's designed to handle various packaging materials, allowing for customized protection strategies based on the product and environmental conditions:

- Material Flexibility: Operators can utilize materials such as:

- Linear Low-Density Polyethylene (LLDPE) stretch film for moisture resistance and load stabilization.

- Volatile Corrosion Inhibitor (VCI) paper or film for superior anti-corrosion protection, crucial for ferrous and non-ferrous metals.

- Crepe paper for cushioning and moisture absorption.

- High-Density Polyethylene (HDPE) woven tape or belts for heavy-duty abrasion resistance.

- Knitted belts for specific surface protection needs.

- Broad Coil Compatibility: These machines are engineered to accommodate a wide spectrum of coil dimensions and weights. For instance, they effectively handle:

- Steel wire coils (low/high carbon, galvanized, stainless).

- Copper and aluminum wire or tube coils.

- PC strand coils.

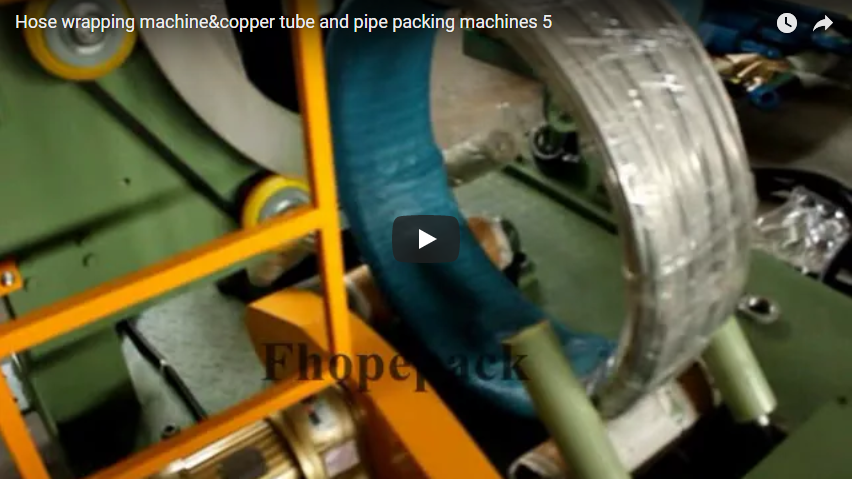

- Hose and pipe coils.

- Bearing rings and other annular products.

- Tailored Wrapping Example: A common application involves wrapping copper tube coils (e.g., OD 500-800mm, ID 400-600mm, Width 100-300mm) using a dual-layer approach. This might involve an inner layer of VCI paper for corrosion prevention followed by an outer layer of stretch film for securing the package and providing a barrier against dust and moisture.

2. Advanced Automation for Precision Wrapping

The operational efficiency and consistency of the wire coil wrapping machine stem from its integrated automation system:

- PLC Control: A Programmable Logic Controller (PLC) serves as the brain, managing the entire wrapping sequence. It allows for storing multiple wrapping programs ("recipes") tailored to different coil types and packaging requirements.

- HMI Interface: A user-friendly Human-Machine Interface (HMI), typically a touchscreen panel, provides operators with intuitive control over machine functions. This includes setting parameters like wrapping speed, overlap percentage, film tension, and number of wraps, as well as accessing diagnostics and status monitoring.

- Sensors and Inverters: Photoelectric sensors detect coil presence and positioning, ensuring accurate wrapping initiation and completion. Variable Frequency Drives (VFDs or inverters) control the speed of the rotating ring/shuttle and the conveyor rollers, enabling smooth acceleration/deceleration and precise control over wrapping tension and material overlap. This precise control minimizes material waste and ensures a consistently tight and secure wrap every time.

- Operational Consistency: Automation eliminates the variability inherent in manual wrapping, ensuring each coil receives the same level of protection according to predefined standards. This contributes significantly to quality control and reduces packaging-related damage claims.

3. Key Technical Specifications (Typical Ranges)

While specifications vary by model, typical parameters for industrial wire coil wrapping machines include:

- Coil Outer Diameter (OD): 500mm - 2000mm+

- Coil Inner Diameter (ID): 300mm - 1500mm+

- Coil Width: 100mm - 800mm+

- Coil Weight: Up to 5000kg+

- Wrapping Ring/Shuttle Speed: 60 - 120 RPM (adjustable)

- Packaging Material Roll Width: 100mm - 300mm

- Packaging Material Roll OD: Up to 500mm

- Control System: PLC + HMI

- Power Supply: Typically 380V/50Hz/3Ph or customized

- Compliance: CE marked, conforms to relevant machinery safety standards.

4. Enhanced Product Protection During Transit and Storage

The primary function is protection. The machine achieves this through:

- Secure Containment: Evenly applied tension and controlled overlap create a stable, tight package that prevents coil telescoping or shifting during handling and transport.

- Environmental Shielding: Appropriate material selection (e.g., stretch film, VCI) provides effective barriers against moisture, dust, dirt, and corrosive elements.

- Surface Protection: Wrapping materials prevent scuffs, scratches, and abrasion damage that can occur from contact with handling equipment or other items during transit.

- Customizable Strategies: The ability to apply multiple layers or different materials allows for tailored protection, such as adding edge protectors automatically or applying specific wrap patterns for maximum stability.

5. Operational Experience: Efficiency Gains and ROI

From an operational perspective, integrating an automated wire coil wrapping machine yields tangible benefits:

- Increased Throughput: Automation significantly speeds up the packaging process compared to manual methods, increasing overall line efficiency. Cycle times are predictable and consistent.

- Reduced Labor Costs: The machine requires minimal operator intervention, primarily for loading/unloading coils (which can also be automated) and replenishing packaging materials. This frees up labor for other value-added tasks.

- Material Savings: Precise control over film stretch, tension, and overlap minimizes material consumption compared to inconsistent manual application. Users often report measurable reductions in material waste.

- Improved Safety: Automating the wrapping process reduces manual handling of heavy coils and repetitive motions associated with hand wrapping, lowering the risk of workplace injuries.

- Ease of Use & Maintenance: Modern HMIs simplify operation and troubleshooting. Machines are generally designed for durability and require routine preventive maintenance, often involving lubrication and sensor checks, contributing to a reliable workflow.

6. Ensuring Compliance and Quality

The consistent output of the automated wrapper helps manufacturers meet quality standards and customer expectations. The CE marking indicates conformity with European health, safety, and environmental protection standards, often a requirement for international trade. The machine's precision ensures that packaging specifications are met reliably for every coil.

Conclusion

The automated wire coil wrapping machine is more than just packaging equipment; it's a strategic investment in product integrity, operational efficiency, and workplace safety. Its versatility in handling diverse coil sizes and materials, combined with advanced automation features like PLC control and sensor integration, delivers consistent, high-quality protective packaging. For manufacturers and distributors in the steel, wire, cable, and related industries, adopting this technology provides a clear path to reducing costs, enhancing product protection, and meeting the rigorous demands of modern supply chains. As industries continue to prioritize efficiency and quality, the automated coil wrapper remains an indispensable tool for ensuring products reach their destination in optimal condition.

info@fhopepack.com