Handling and packaging large, flat materials like gypsum board, door panels, and sheet goods presents significant challenges in manufacturing and distribution environments. Ensuring product integrity while maintaining operational efficiency necessitates advanced automated solutions. Horizontal orbital wrapping technology, exemplified by specialized machinery, offers a robust method for securely packaging these items.

Optimizing the Packaging of Large-Format Panels

Manual or semi-automated methods for wrapping bulky items such as gypsum boards, architectural panels, doors, and windows often lead to inconsistencies, potential product damage from handling, and increased labor costs. The sheer size and weight demand stable, protective packaging to prevent shifting, moisture ingress, and surface abrasion during transit and storage. Traditional shrink wrapping can be energy-intensive, while manual stretch wrapping lacks speed and uniformity.

Advanced Horizontal Orbital Wrapping: Technical Insights

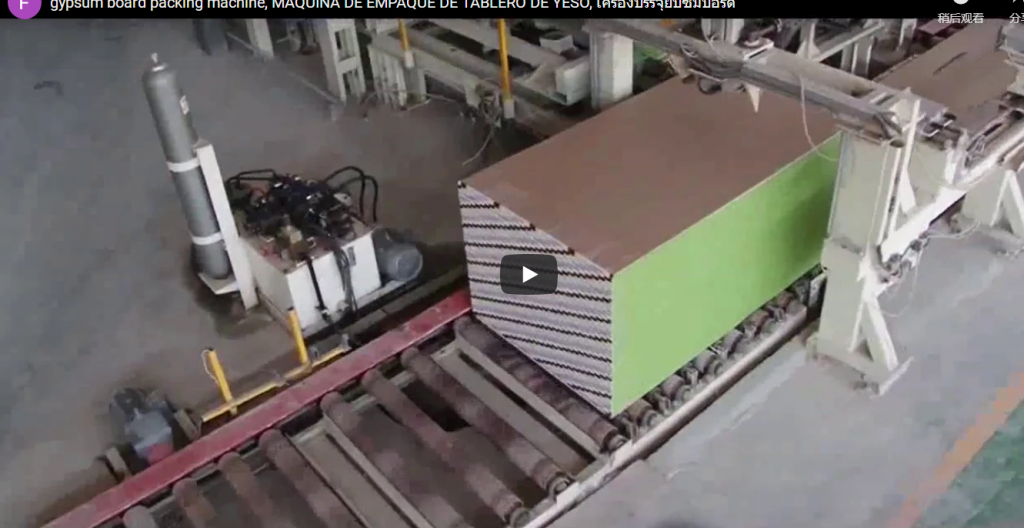

The Fhopepack gypsum board packing machine utilizes horizontal orbital wrapping principles, a technique well-documented for its effectiveness in securing elongated or flat products (Ref: Packaging Technology and Science Journal insights on stretch film dynamics). Key operational features and technical parameters often include:

- Wrapping Mechanism: Employs a rotating ring carrying a stretch film dispenser that orbits horizontally around the product as it feeds through the machine.

- Film Delivery System: Incorporates powered pre-stretch capabilities (potentially achieving 200-300% stretch, maximizing film yield and load containment, a concept discussed in various packaging machinery patents, e.g., relating to film tension control).

- Control System: Typically managed by a Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) for setting parameters like wrap counts, ring speed, conveyor speed, and film tension. (Ref: Common architecture in industrial automation control systems).

- Turning Station: Integrated device for rotating the product (e.g., 90 degrees) if required for specific wrapping patterns or line layouts.

- Typical Throughput: Designed for varying production needs, potentially handling 20-60 panels per hour depending on size and wrap configuration.

- Safety Features: Conforms to industry safety standards, often incorporating light curtains, safety interlocks, and emergency stops (Ref: ISO 13849 / EN ISO 12100).

Seamless Integration into Automated Production Lines

Designed for integration, this type of orbital wrapper can function as a standalone unit or as a critical component within a larger horizontal panel packing line. It readily interfaces with powered infeed and outfeed conveyors, aligning with automated material handling systems prevalent in modern manufacturing facilities. This synergy minimizes manual touchpoints, reduces bottlenecks, and enhances overall plant productivity.

Core Benefits for Industrial Operations

Implementing automated horizontal wrapping delivers tangible advantages:

- Superior Product Protection: Creates a tightly sealed, multi-layered barrier against dust, moisture, and surface damage.

- Enhanced Load Stability: Uniform film tension secures the product, preventing shifting during handling and transport, crucial for breakable items like gypsum.

- Optimized Material Usage: Precise pre-stretch control significantly reduces stretch film consumption compared to manual methods.

- Increased Operational Efficiency: Automates a labor-intensive process, boosting throughput and enabling personnel reallocation.

- Professional Package Presentation: Delivers consistently neat, tidy, and secure packages, enhancing brand perception.

Versatile Applications Across Industries

While designated as a 'gypsum board packing machine,' its horizontal wrapping capability is ideally suited for a wide range of flat or elongated products across various sectors:

- Building Materials: Gypsum board, insulation panels, plywood sheets, siding.

- Fenestration: Windows, door frames, door panels.

- Flooring: Hardwood flooring bundles, laminate planks.

- Furniture: Tabletops, flat-pack furniture components, cabinets.

The system is typically adaptable to handle varying product dimensions (e.g., lengths up to 5 meters, widths up to 1.5 meters) and weights, subject to specific machine configuration.

In summary, Fhopepack's horizontal orbital wrapping solution represents a significant upgrade for facilities handling large panel-type products. By automating the wrapping process, it enhances product protection, optimizes resource utilization, and contributes to a more efficient and safer production environment.

For detailed specifications, customization options, or to discuss how this technology can address your specific packaging challenges, please contact Fhopepack.

info@fhopepack.com