Foam glass, a lightweight yet rigid material prized for its exceptional thermal insulation, fire resistance, and impermeability (properties often detailed in architectural material specifications and standards like ASTM C552), poses specific challenges for secure and efficient packaging. Protecting its structural integrity, particularly edges and corners, from the production line to the installation site is paramount. Automated shrink wrapping systems, specifically engineered for large-format, rigid materials, provide a technically advanced and operationally efficient solution for manufacturers and distributors handling foam glass insulation panels.

1. Advanced Packaging System Design: Integrating Sealing and Shrinking

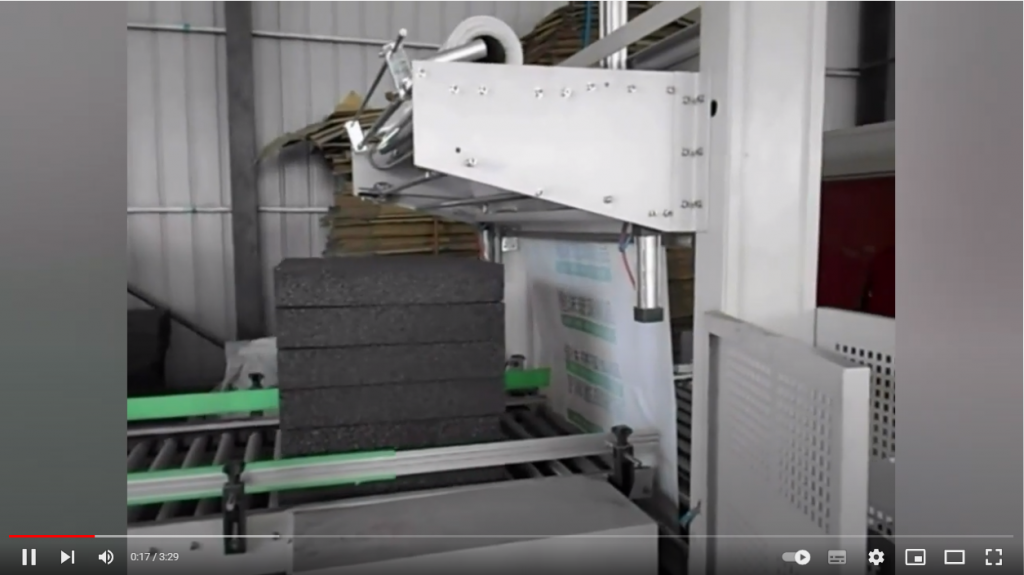

The showcased system exemplifies a modern, integrated packaging line designed for high-throughput operations involving substantial product dimensions. This configuration typically comprises two critical, synchronized modules:

-

Automatic L-Bar Sealing Station: This unit employs an L-shaped sealing bar to precisely cut and seal polyolefin or polyethylene shrink film, creating a complete enclosure around the foam glass panel or a stack of panels. Key design features often include:

- Precision Temperature Control: Utilizing PID (Proportional-Integral-Derivative) controllers for consistent seal wire temperature, ensuring strong, reliable seals across varying film thicknesses and ambient plant temperatures. This is crucial for preventing film burn-through or weak seals.

- Pneumatic or Servo-Driven Seal Jaw: Ensures consistent sealing pressure for uniform seals. Servo drives offer greater control over speed and pressure profiles.

- Film Tensioning System: Maintains optimal film tension during dispensing and sealing to prevent wrinkles and ensure a snug initial wrap.

- Product Sensing: Photo-eyes or laser sensors detect incoming products, triggering the sealing cycle automatically and ensuring accurate product positioning relative to the seal bar. Typical sealing cycle times range from 2-5 seconds depending on product size and film type.

-

High-Performance Shrink Tunnel: Immediately following the sealing station, the loosely bagged product is conveyed into an extended shrink tunnel. Optimal shrinkage relies on carefully managed thermodynamics:

- Recirculating Hot Air Convection: High-volume blowers and precisely positioned ducting ensure turbulent, uniform hot air distribution (typically ranging from 150°C to 220°C, adjustable) around all surfaces of the package. This prevents hot spots that could damage the foam glass or film.

- Variable Speed Conveyor: Allows precise control over dwell time within the tunnel (ranging from 10 to 30 seconds, typically), critical for achieving optimal film shrinkage without overheating the substrate. Conveyor types often include heat-resistant belts or live rollers.

- Adjustable Airflow Dampers: Enable fine-tuning of air velocity and direction within the tunnel to accommodate different product sizes and shapes, ensuring the film shrinks tightly and uniformly.

- Energy Efficiency Features: Modern tunnels incorporate advanced insulation and efficient heating elements to minimize energy consumption, a key operational cost factor.

This specific Foam glass panel packing machine for insulation panel shrinking machine features an appropriately dimensioned sealing area (specify dimensions if known, e.g., "up to 1500mm long x 800mm wide") and a correspondingly long shrink tunnel ("e.g., 2500mm heating chamber length") to guarantee sufficient sealing capacity and heat exposure for complete, uniform shrinkage on large foam glass panels.

2. Technical Data & Performance Comparison Highlights

| Feature | Automated Shrink Wrap System | Manual / Semi-Auto Methods | Benefit |

|---|---|---|---|

| Throughput | 5-15+ Packs/Minute (Typical) | 1-4 Packs/Minute | Significant increase in packaging speed, reduces bottlenecks. |

| Labor Requirement | 0-1 Operator (Monitoring) | 1-3+ Operators | Drastic reduction in direct labor costs per package. |

| Package Consistency | High / Uniform | Variable | Ensures consistent product protection and professional appearance. |

| Seal Integrity | High / Electronically Controlled | Operator Dependent | Reduces package failures during handling and transit. |

| Film Usage | Optimized / Minimal Waste | Higher Potential Waste | Lower consumable costs, improved sustainability. |

| Product Protection | Excellent (6-sided) | Moderate to Good | Comprehensive barrier against dust, moisture, scuffs. |

| Load Stability | Good to Excellent | Variable | Unitizes panels effectively for safer stacking and transport. |

| Capital Investment | Higher | Lower | ROI achieved through labor savings, speed, and reduced damage/waste. |

| Operational Cost | Lower (per unit) | Higher (per unit) | Driven by labor efficiency and optimized material use. |

3. Key Operational Advantages and Efficiency Gains

Transitioning to automated shrink wrapping for foam glass panels delivers measurable improvements across the packaging workflow, aligning with efficiency goals often cited in logistics and manufacturing publications:

- Superior Product Protection: The tightly shrunk film provides a robust barrier against environmental contaminants (dust, moisture) and physical damage (scratches, abrasions) during handling, storage, and transportation. This preserves the pristine condition and insulating performance of the foam glass. The complete enclosure offered is superior to strapping or simple bagging.

- Enhanced Load Unitization and Stability: Shrink wrapping consolidates single or multiple panels into a secure, stable unit. This significantly improves pallet stability, reduces shifting during transit, minimizes breakage risk, and facilitates easier, safer handling with forklifts or other equipment.

- Significant Throughput Increase: Automation dramatically boosts packaging speed compared to manual methods. Sensor-driven activation, PLC-controlled sequencing, and integrated conveyors enable continuous flow operation, capable of matching upstream production rates (e.g., achieving rates of 8-12 panels per minute, depending on size and configuration).

- Reduced Labor Dependency and Costs: Automating the sealing and shrinking processes drastically cuts down on the manual labor required per package. This allows personnel to be reassigned to higher-value tasks, mitigating ergonomic risks associated with repetitive manual wrapping and reducing overall labor expenditure.

- Optimized Consumable Usage: Precision film delivery, cutting, and sealing systems minimize shrink film waste compared to manual cutting or less sophisticated wrapping techniques. Consistent heat application ensures optimal shrinkage without excessive film usage.

- Professional and Marketable Package: A clear, taut, and uniform shrink wrap enhances the product's visual appeal on the pallet and at the point of sale or delivery. It allows for easy product identification and conveys a higher standard of quality control.

4. Suitability for Foam Glass Material Properties

Shrink wrapping is particularly well-suited for foam glass due to the interaction between the film and the material's characteristics:

- Non-Compressive Conformability: The heat-shrinking process allows the film to conform tightly to the panel's shape, including securing edges, without applying significant compressive force that could damage the rigid, cellular structure of foam glass.

- Effective Dust and Particle Containment: The complete film enclosure reliably contains any fine dust or particles that might be present on the surface of the foam glass, ensuring cleaner handling and storage environments.

- Product Visibility: Using clear shrink film allows for easy visual inspection of the panel's condition, identification markings, or labels without needing to remove the packaging.

5. Conclusion: Optimizing Insulation Panel Packaging

Automated shrink wrapping systems, integrating sophisticated L-bar sealing technology with precisely controlled shrink tunnels, represent a best-in-class solution for the demanding task of packaging foam glass insulation panels. The demonstrable benefits—ranging from superior product protection and load integrity to significant gains in operational throughput and labor efficiency—provide a compelling case for investment. These systems ensure that high-value insulation products are delivered to the end-user in optimal condition, reflecting the quality of the product within. Adopting such automation aligns perfectly with the broader industry push towards enhanced efficiency, reduced waste, and improved supply chain resilience in the building materials sector, topics frequently explored in publications like Packaging World.

For further technical specifications, customization options, or a consultation regarding your specific foam glass packaging requirements, please contact:

info@fhopepack.com