Revolutionizing Wire Handling: A Deep Dive into the Automatic Steel Wire Coiler & Strapping Machine

In today's demanding manufacturing landscape, efficiency, precision, and cost-effectiveness are paramount, especially in the steel wire industry. Manual or semi-automated wire coiling and strapping processes often present significant challenges, including inconsistent results, high labor dependence, and potential safety risks. Enter the Automatic Steel Wire Coiler – a fully integrated solution designed to streamline these critical operations. This article delves into the technical capabilities, operational benefits, and real-world impact of this advanced machinery.

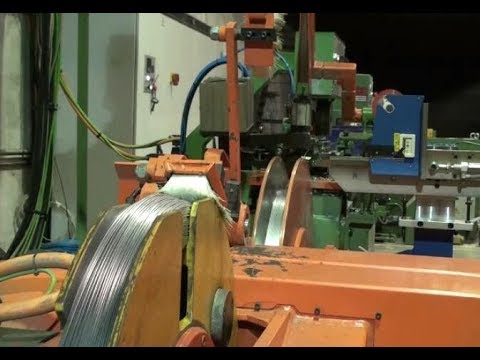

See the machine in action:

1. The Challenge: Overcoming Manual Wire Coiling Inefficiencies

Traditional wire handling methods often involve significant manual labor for both winding steel wire into coils and subsequently securing them for transport or storage. This approach typically suffers from:

- Inconsistency: Manual winding can lead to variations in coil tightness, shape, and dimensions.

- Low Throughput: The speed is limited by human operators, creating potential production bottlenecks.

- Labor Costs: Significant manpower is required, impacting operational expenses.

- Safety Concerns: Handling heavy wire and operating strapping tools manually carries inherent risks.

- Material Waste: Improper winding or strapping can lead to damaged product.

Addressing these pain points is crucial for manufacturers seeking to remain competitive.

2. Introducing the Automatic Steel Wire Coiler: A Game Changer

The Automatic Steel Wire Coiler represents a significant leap forward. It's not just a winder; it's a sophisticated system engineered to manage the entire process from taking the wire feed to producing a securely strapped, ready-to-ship coil. Its fully automated nature minimizes human intervention, maximizing efficiency and consistency.

3. Core Functionality: Precision Winding Explained

At its heart, the machine employs advanced mechanisms for highly accurate wire coiling:

- PLC Control: A Programmable Logic Controller serves as the brain, managing all operations and allowing for precise parameter adjustments.

- Servo-Driven Systems: Often utilized for winding and traversing, ensuring smooth motion, precise wire layering, and consistent tension control.

- Adjustable Parameters: Operators can easily set and modify key specifications via a user-friendly interface (HMI), including:

- Target coil inner diameter (ID)

- Target coil outer diameter (OD) or weight

- Coil width

- Wire traversing pitch

- Winding speed

- Tension Control: Maintaining consistent wire tension during winding is critical for producing stable, high-quality coils. Automatic systems often incorporate dynamic tensioning mechanisms.

This level of control ensures every coil meets exact specifications, reducing variability and improving downstream handling.

4. Integrated Strapping: Securing Your Coils Automatically

Once the desired coil size is reached, the integrated strapping system takes over:

- Automatic Strap Feeding: The system automatically positions the strapping material (typically PET or steel) around the coil.

- Tensioning & Sealing: It applies the pre-set tension to the strap and then securely seals it, often using heat sealing or friction-welding techniques for plastic straps, or mechanical seals for steel straps.

- Multiple Straps: The system can be programmed to apply multiple straps at designated points around the coil circumference for enhanced stability.

- Coil Ejection: After strapping, the finished coil is typically ejected automatically onto a conveyor or collection table.

This seamless integration eliminates the need for a separate strapping station and associated manual handling, further boosting efficiency and protecting the coil integrity.

5. Key Technical Specifications & Features (Typical Parameters)

While exact specifications vary by model and manufacturer, typical parameters often include:

- Wire Diameter Range: e.g., 1.0mm - 8.0mm

- Coil Inner Diameter (ID): e.g., Adjustable from 300mm - 600mm

- Coil Outer Diameter (OD): e.g., Up to 1200mm

- Max Coil Weight: e.g., 50kg - 500kg (or higher for heavy-duty models)

- Coiling Speed: e.g., Up to 150 m/min (variable)

- Strapping Material: PET / PP / Steel Strapping

- Number of Straps: Typically 3 or 4, positions adjustable

- Control System: PLC with HMI Touch Screen

- Power Requirements: Specified voltage/frequency (e.g., 380V/50Hz/3Ph)

- Safety Features: Emergency stops, safety guarding, interlocks.

6. The ROI Perspective: Beyond Simple Automation

Investing in an Automatic Steel Wire Coiler delivers tangible returns:

- Reduced Labor Costs: Frees up personnel for higher-value tasks.

- Increased Throughput: Significantly faster coiling and strapping cycles boost overall production capacity.

- Improved Product Quality: Consistent winding and secure strapping lead to better coil integrity and presentation.

- Enhanced Safety: Minimizes manual handling of heavy wire and reduces exposure to strapping operations.

- Material Savings: Precise control can reduce wire scrap and optimize strapping material usage.

- Operational Efficiency: Streamlines workflow from wire drawing/processing to final packaging.

7. Real-World Impact: A Personal Insight

From interactions within the industry, the adoption of automated coiling and strapping systems like this marks a pivotal shift. Manufacturers consistently report not just cost savings, but a noticeable improvement in logistical efficiency. Well-formed, securely strapped coils are easier and safer to stack, store, and transport. Furthermore, the professional appearance of the finished product often enhances customer perception and satisfaction. It moves wire packaging from a purely functional necessity to a value-added component of the supply chain.

8. Choosing the Right Coiler: What to Consider

Selecting the appropriate machine requires careful evaluation of:

- Production Volume: Match machine capacity to your output needs.

- Wire Specifications: Ensure compatibility with your wire types, diameters, and tensile strengths.

- Coil Requirements: Match the machine's capabilities for ID, OD, weight, and width.

- Level of Automation: Consider integration needs with upstream and downstream equipment.

- Strapping Needs: Evaluate requirements for strap type, number, and tension.

- Space and Utilities: Ensure sufficient floor space and adequate power/air supply.

- Supplier Support: Consider installation, training, maintenance, and spare parts availability.

In conclusion, the Automatic Steel Wire Coiler with integrated strapping is far more than just a machine; it's a strategic investment for wire manufacturers aiming to optimize operations, enhance product quality, and improve their competitive edge. By automating repetitive and labor-intensive tasks with precision and reliability, it paves the way for greater productivity and profitability.

For inquiries or further technical details:

info@fhopepack.com

Explore related solutions:

https://www.fhopepack.com/Wire-coil-wrapping-machine/