Optimizing Post-Extrusion Operations: The Advanced Automatic Pipe Bundling, Strapping, and Bagging System

In the competitive landscape of plastic pipe manufacturing for sectors like construction, utilities, and agriculture, optimizing end-of-line operations is paramount. Manual handling of pipes is often labor-intensive, prone to inconsistencies, and can introduce risks of product damage and worker injury. Addressing these challenges requires sophisticated automation, as exemplified by the integrated automatic plastic pipe bundling, strapping, and bagging machine. This system represents a significant leap forward from traditional methods, offering enhanced efficiency, consistency, and protection for finished pipe products.

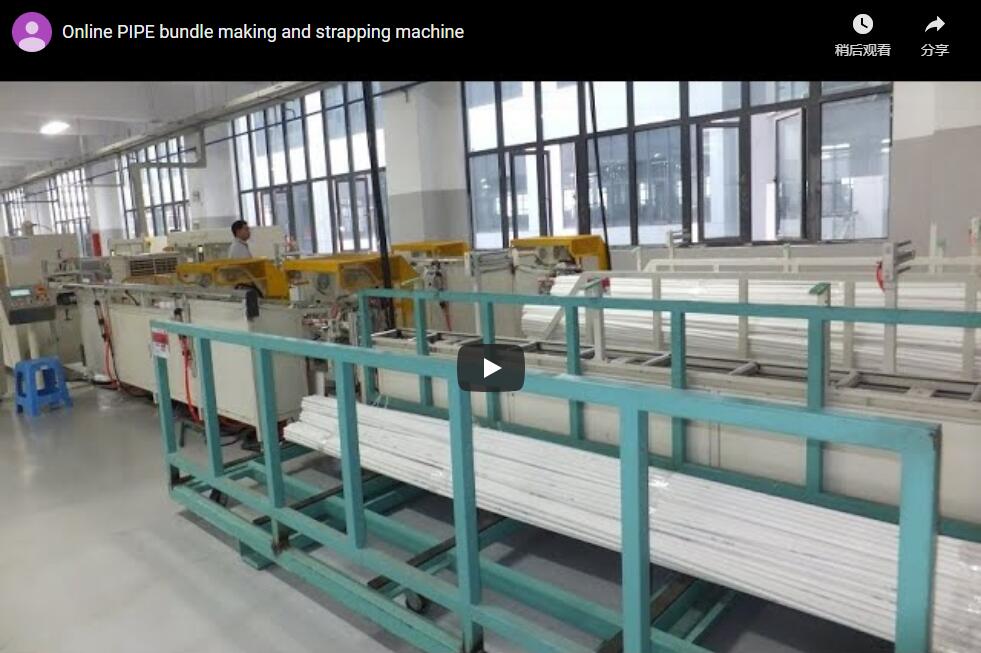

Streamlining the Workflow: From Loose Pipes to Secured Bundles

The core value of this automated system lies in its ability to seamlessly integrate three critical post-extrusion processes:

1. Precision Collation and Bundling

The process commences with the automated collection of individual plastic pipes. Advanced sensors and conveyor systems ensure accurate counting and alignment as pipes are gathered into a designated chute or collection area.

- Mechanism: Utilizes servo-driven pushers or accumulation belts for gentle handling.

- Configuration: Systems often feature adjustable guides and counters to accommodate varying pipe diameters (e.g., PVC, HDPE, PEX) and desired bundle sizes (hexagonal, square configurations), aligning with principles seen in material handling automation patents focusing on adaptable gripping and sorting (Ref: Concepts potentially related to USPTO Class B65G - Conveyors).

- Output: Consistently formed, neat bundles ready for stabilization.

2. Secure Strapping or Stretch Wrapping

Once the desired count is achieved, the bundle is transferred to the strapping or wrapping station. Depending on configuration and application requirements:

- Stretch Wrapping: Often employs orbital stretch wrapping technology, applying multiple layers of stretch film around the bundle circumference. This method provides excellent load containment and protection against surface scratches and environmental contaminants. Research in packaging science highlights the importance of film pre-stretch and tension control for optimal load stability and material efficiency.

- Strapping: Alternatively, the system can utilize plastic (PP or PET) strapping, applying bands at pre-set intervals. Advanced strapping heads ensure consistent tension without damaging the pipe surface, a critical factor noted in industry best practices for handling plastic materials.

3. Protective Bagging and Sealing

The final automated stage involves enclosing the strapped or wrapped bundle within a protective plastic bag.

- Process: Typically involves dispensing a pre-made bag or forming a bag from polyethylene film roll stock, inserting the bundle, and creating a secure heat seal. This step adds a crucial layer of protection against UV degradation, dust, and moisture during storage and transportation.

- Efficiency: Automating this step eliminates manual bagging bottlenecks, significantly improving overall line throughput, a key metric emphasized in publications like Packaging World when evaluating end-of-line automation ROI.

Technological Advantages and Operational Gains

The automatic plastic pipe bundling, strapping and bagging machine integrates several key technologies to deliver tangible benefits:

- PLC Control & HMI: Centralized Programmable Logic Controller (PLC) systems with user-friendly Human-Machine Interfaces (HMIs) allow for easy operation, parameter adjustments (bundle count, strapping tension, bag length), recipe management, and diagnostics. Integration capabilities often allow connection to plant-level MES or SCADA systems.

- Robust Construction: Built with industrial-grade materials and components designed for durability and reliable performance in demanding manufacturing environments.

- Enhanced Safety: Incorporates safety guarding, emergency stop circuits, and sensors to protect operators, complying with relevant machinery safety standards (e.g., ISO 13849).

- Increased Throughput: Drastically reduces the time required compared to manual methods, enabling higher production output.

- Labor Optimization: Frees up personnel from repetitive manual tasks, allowing them to focus on quality control and other value-added activities. Studies on manufacturing automation consistently show significant labor cost reductions and improved ergonomics.

- Improved Product Quality & Consistency: Automated handling minimizes scratches, deformation, and contamination. Consistent strapping/wrapping and bagging ensure uniform package quality and integrity.

- Reduced Material Waste: Optimized use of stretch film or strapping material through precise control systems.

Strategic Investment for Pipe Manufacturers

Implementing an automatic plastic pipe bundling, strapping, and bagging system is more than an equipment upgrade; it's a strategic investment in operational efficiency, product quality, and workplace safety. By automating these end-of-line tasks, manufacturers can significantly reduce bottlenecks, lower operational costs, enhance product presentation, and improve their competitive edge in the market. This comprehensive solution provides a reliable, efficient, and modern approach to handling finished plastic pipe products.

For more detailed specifications or to discuss how this system can be integrated into your specific production line, please contact info@fhopepack.com.