Optimizing Cable Packaging: Technical Insights into Automatic Cable Strapping Machines

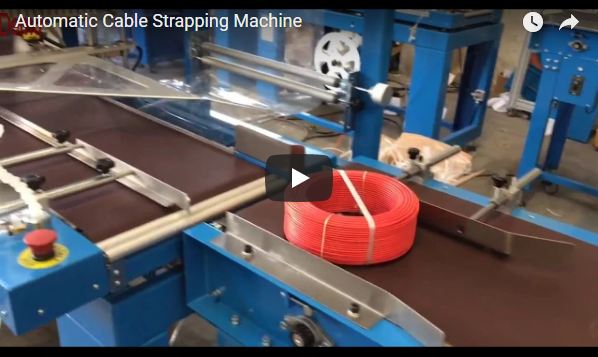

In high-volume cable and wire manufacturing, efficient and secure packaging is paramount. Manual or semi-automatic methods often struggle to keep pace with production output, leading to bottlenecks and inconsistencies. Automatic cable strapping machines represent a critical technological step forward, automating the process of securing cable coils before subsequent handling, storage, or processes like shrink wrapping. This detailed look explores the operation, benefits, and technical considerations of these essential industrial machines.

1. Understanding the Core Mechanics

An automatic cable strapping machine streamlines a multi-step process into a seamless, automated cycle:

- Coil Positioning: The cable coil is typically transferred onto the machine's strapping station, often via conveyor or robotic handling. Sensors confirm correct positioning.

- Strap Feeding: The strapping head automatically feeds the required length of strapping material (commonly PET or PP) around the coil's circumference through an arched track or guide system.

- Tensioning: Once the strap encircles the coil, a tensioning mechanism applies a pre-set, controlled force to tighten the strap securely. From experience, precise tension calibration is crucial – too loose, and the coil isn't secure; too tight, and it could damage softer cable jackets. Consistent tension is a key advantage over manual methods.

- Sealing: The overlapping ends of the strap are joined. Common methods include heat sealing (melting the strap ends together) or friction welding (using high-speed vibration to generate heat and fuse the material). Friction welds often provide higher joint strength, particularly with PET strapping.

- Cutting: The strap is cut cleanly near the seal.

- Ejection/Transfer: The strapped coil is then moved off the station, ready for the next stage (e.g., shrink wrapping, palletizing).

The entire cycle is typically managed by a Programmable Logic Controller (PLC), allowing for parameter adjustments and integration with other factory systems.

2. Key Technical Specifications and Considerations

Selecting the appropriate automatic cable strapping machine requires careful evaluation of several parameters:

- Coil Dimensions:

- Minimum/Maximum Outer Diameter (OD)

- Minimum/Maximum Inner Diameter (ID)

- Minimum/Maximum Coil Width/Height

- Strapping Material:

- Type: Primarily Polyethylene Terephthalate (PET) or Polypropylene (PP). PET generally offers higher tensile strength and retained tension, making it suitable for heavier or more demanding applications.

- Width: Common sizes range from 9mm to 19mm.

- Thickness: Varies depending on strength requirements.

- Performance:

- Cycle Time: How quickly can the machine process one coil? (e.g., 15-30 seconds).

- Tension Range: Adjustable force applied (e.g., 15-70 kg).

- Number of Straps: Ability to apply single or multiple straps per coil.

- Control System:

- PLC Brand and capabilities (e.g., Siemens, Allen-Bradley, Omron).

- Human-Machine Interface (HMI) for operation and diagnostics.

- Integration: Compatibility with existing conveyor systems and factory automation networks (e.g., Profinet, Ethernet/IP).

Personal Insight: Consider future needs. Choosing a machine with slightly broader coil dimension capacity or faster potential cycle time than currently required can provide valuable flexibility for future product variations or production increases.

3. Integration and Workflow Optimization

Stand-alone strapping is useful, but the real efficiency gains come from integrating the automatic cable strapping machine into a complete packaging line.

- Infeed/Outfeed: Smooth integration with conveyors feeding coils from winders/coilers and transferring strapped coils to shrink tunnels or palletizers is essential to maintain throughput.

- PLC Integration: Connecting the strapper's PLC to a central plant control system (like SCADA or MES) allows for centralized monitoring, recipe management (pre-set parameters for different coil types), and fault diagnostics. This reduces operator intervention and speeds up changeovers.

- Workflow Impact: Automation eliminates manual handling risks associated with tensioning and cutting tools. It ensures every coil is strapped identically, improving load stability and reducing the chance of coils unraveling during transit – a common issue with inconsistent manual strapping.

4. Benefits Beyond Speed: Consistency and Protection

While increased speed and reduced labor costs are primary drivers, the advantages extend further:

- Consistent Quality: Automated tensioning and sealing ensure every strap is applied with the same force and secure seal, regardless of operator variation. This predictability is vital for package integrity.

- Product Protection: Secure strapping prevents cable layers from shifting or loosening within the coil, protecting the cable from damage during handling, stacking, and shipping.

- Enhanced Package Appearance: Uniformly strapped coils present a more professional and tidy appearance, enhancing brand perception. A well-secured package implies product quality.

- Improved Logistics: Tightly strapped coils are often more compact and stable, potentially optimizing storage space and transportation density.

5. The Fhopepack Approach

Solutions like the automatic cable strapping machine from Fhopepack are engineered to address these industry needs. They typically feature robust construction, reliable PLC control systems, and configurations designed to handle a diverse range of cable coil specifications using durable PET strapping. The focus is on providing a dependable, automated solution that integrates seamlessly into production lines, delivering the consistency and efficiency required in modern cable manufacturing. After strapping, coils are often ready for the shrinking process, which further tightens the packaging for maximum protection.

For more details on integrated coiling and packaging solutions, see:

Automatic Cable Coiling and Wrapping Machine Information

Conclusion

Automatic cable strapping machines are no longer a luxury but a necessity for competitive cable and wire manufacturers. By automating a critical packaging step, they deliver significant improvements in speed, consistency, labor efficiency, and product protection. Careful consideration of technical specifications and integration possibilities ensures that the chosen machine provides maximum value, contributing to a streamlined, reliable, and cost-effective packaging operation. The result is a securely packaged product, ready for market with enhanced integrity and appearance.

For inquiries or further technical discussion:

info@fhopepack.com