Enhancing Aluminum Profile Integrity with Automated Protective Film Application

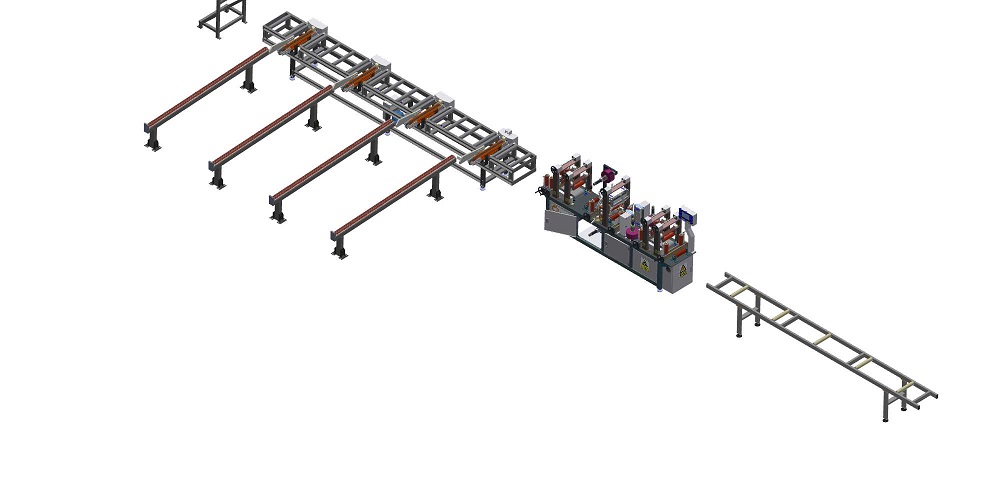

Protecting the surface integrity of aluminum profiles during handling, fabrication, storage, and transit is paramount in modern manufacturing. Scratches, abrasions, and contamination can lead to costly rework or scrap, impacting profitability and product quality. Addressing this challenge, automated protective tape application systems represent a significant technological advancement for aluminum extruders and fabricators. The system detailed herein offers a robust, high-efficiency solution for applying protective film to all four sides of aluminum profiles.

Advanced Automation for Uncompromised Surface Protection

This automatic aluminum profile tape applicator integrates several key technologies to deliver consistent and reliable performance. It automates the entire process, from infeed to outfeed, minimizing manual intervention and maximizing throughput.

Core Process Automation:

- Automatic Feeding: Profiles are systematically fed into the application zone.

- Precision Positioning: A servo-driven system ensures accurate profile placement, critical for consistent tape alignment along the entire length. This level of precision, often achieving tolerances within millimeters, is vital for edge-to-edge protection, a feature highlighted in recent advancements discussed in metal fabrication journals.

- Film Application: Protective tape is applied smoothly and evenly to all four surfaces simultaneously or sequentially, depending on the configuration. Tension control systems, often incorporating feedback loops (as suggested in process automation research), ensure optimal adhesion without stretching or damaging the film or profile.

- Automated Cutting: The machine automatically calculates the required tape length based on the profile dimensions and executes a clean, precise cut, minimizing waste and ensuring a neat finish. Technologies similar to those patented for web handling and cutting (e.g., rotary shear mechanisms) are often employed.

- Controlled Out-feeding: Finished profiles are smoothly transferred out of the machine, ready for the next stage in the production or packaging process.

Key Technical Specifications and Operational Flexibility

Understanding the machine's capabilities is crucial for assessing its fit within a specific production environment.

- Profile Length Capacity: Designed to handle standard industry lengths, typically ranging from 4.0 meters (approx. 13 feet) up to 7.8 meters (approx. 25.5 feet). Custom ranges may be available.

- Control System: Utilizes a Programmable Logic Controller (PLC) with a user-friendly Human-Machine Interface (HMI) for parameter setting, process monitoring, and diagnostics. This aligns with Industry 4.0 principles for accessible machine control.

- Drive Mechanism: High-precision servo motors govern the feeding and positioning systems, ensuring repeatability and accuracy essential for high-quality application.

- Tape Management: Features automatic tape length calculation and pre-cutting capabilities, optimizing material usage. Adjustable tension control accommodates various film types and thicknesses.

- Operating Modes: Offers both fully automatic operation for maximum efficiency and semi-automatic mode for handling non-standard profiles or smaller batches, providing operational flexibility.

- Integration Potential: Engineered for seamless integration into existing production lines. It can be configured for online connection downstream from aluminum extrusion presses or upstream from painting or anodizing lines, creating a streamlined, low-touch workflow. This integration capability is a key focus in modern plant efficiency studies.

Benefits for Aluminum Extruders and Fabricators

Implementing an automated tape application system delivers tangible advantages:

- Superior Surface Protection: Consistent, full-coverage application significantly reduces the risk of surface damage, enhancing final product quality and minimizing rejects.

- Increased Throughput: Automation drastically speeds up the application process compared to manual methods, boosting overall production capacity. Cycle times become predictable and optimized.

- Reduced Labor Costs: Automating this repetitive task frees up personnel for higher-value activities and reduces direct labor expenditure.

- Enhanced Consistency and Quality: Eliminates the variability inherent in manual application, ensuring every profile receives uniform protection according to set parameters. Adhesion quality and edge alignment are significantly improved.

- Improved Safety: Reduces manual handling of long profiles and interaction with cutting tools.

Design, Reliability, and Maintenance

Built for demanding industrial environments, these applicators typically feature robust steel frames and employ high-quality components sourced from reputable suppliers. Design considerations often focus on:

- Durability: Ensuring long service life under continuous operation.

- Ease of Maintenance: Providing accessible components for routine cleaning, inspection, and servicing, minimizing downtime. Quick-change mandrels for tape rolls are often standard.

- Reliability: Leveraging proven automation technologies (PLCs, servos, sensors) to maximize uptime.

Conclusion: A Strategic Investment in Quality and Efficiency

The automatic aluminum profile tape applicator is more than just a machine; it's a strategic tool for maintaining product quality, optimizing workflow, and enhancing the competitiveness of aluminum extrusion and fabrication operations. By automating the critical task of surface protection, businesses can achieve higher efficiency, reduce waste, and ensure their products reach customers in pristine condition. This technology aligns perfectly with the industry's push towards greater automation and quality control.

For further details on solutions for aluminum processing and packaging:

https://www.fhopepack.com/Aluminum/

Contact for inquiries: info@fhopepack.com