Automated Cable Packing Lines: Enhancing Efficiency and Quality in Cable Handling

Handling and packaging cables and wires efficiently and consistently presents a significant challenge in manufacturing and distribution environments. Manual processes can be labor-intensive, prone to inconsistencies, and struggle to keep pace with production demands. Automated cable packing lines offer a comprehensive solution, integrating multiple processes to streamline operations, reduce costs, and improve final product quality.

This article provides a technical overview of the components, operation, and benefits of automated cable packing lines, sharing insights into their real-world application.

Understanding the Core Components of an Automated Cable Packing Line

A typical automated cable packing system integrates several key stages to transform loose cable into a securely packaged, labeled product ready for shipment or storage.

1. Precision Cable Coiling

The process begins with the coiling system, which winds the cable or wire into neat, manageable coils.

- Mechanism: Usually employs a rotating mandrel or coiling head that winds the cable fed from a payoff or extruder. Advanced systems feature adjustable traverse mechanisms for level winding and precise coil dimensions.

- Control: Tension control is critical to prevent cable damage and ensure consistent coil density. Speed synchronization with upstream processes is essential.

- Technical Parameters: Key specifications include compatible cable diameter range (e.g., 1-10mm), maximum coil outer diameter (OD), inner diameter (ID), coil width/height, and coiling speed (meters/minute).

- Benefit: Automating this stage dramatically increases speed and ensures uniform coil shape and size, improving handling and downstream processing.

2. Secure Coil Strapping

Once coiled, the cable needs to be secured to prevent unwinding during handling and transport.

- Mechanism: An automated strapping unit applies bands (typically Polypropylene - PP, or sometimes PET) around the coil's circumference at one or multiple points. Common methods include heat sealing or friction welding to join the strap ends.

- Control: Strap tension and the number/position of straps are usually adjustable parameters.

- Technical Parameters: Important factors are strap width compatibility (e.g., 5-12mm), maximum strapping tension, and cycle time per strap.

- Benefit: Ensures coil integrity, prevents tangling, and maintains a compact form factor for packaging.

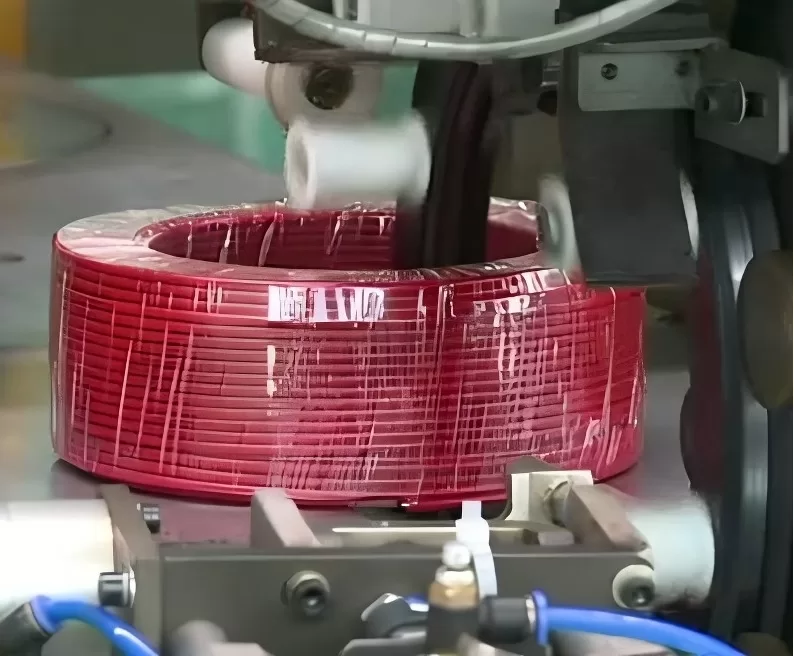

3. Protective Shrink Wrapping

For enhanced protection and stability, many lines incorporate a shrink-wrapping module.

- Mechanism: The strapped coil is typically passed through a station that applies a layer of shrink film (often Polyethylene - PE) before entering a heat tunnel. The controlled heat causes the film to shrink tightly around the coil.

- Control: Parameters like conveyor speed through the tunnel and tunnel temperature are precisely controlled based on the film type and coil size.

- Technical Parameters: Specifications include maximum coil dimensions the tunnel can accommodate, film roll width/diameter limits, temperature range, and throughput capacity. Learn more about shrink film materials here.

- Benefit: Provides excellent protection against dust, moisture, and abrasion during transit and storage. It also further unitizes the coil and offers a surface for labeling.

4. Informative Labeling

The final automated step is often labeling.

- Mechanism: Automated labeling systems can range from simple date/batch code printers to sophisticated print-and-apply systems that generate labels with barcodes, logos, product specifications, and traceability information. Labels are typically applied to the flat side of the coil or the shrink wrap.

- Control: Integration with production databases allows for dynamic data printing. Vision systems can verify label placement and readability.

- Technical Parameters: Considerations include label size range, print resolution, application speed, and data interface capabilities.

- Benefit: Crucial for product identification, inventory management, traceability, and providing essential information to the end-user.

System Integration and Control

The seamless operation of these distinct modules relies on sophisticated integration and control systems.

- Conveyor Systems: Automated conveyors (belt, roller, or chain) transport the cable and coils between stages, ensuring smooth workflow and minimizing manual handling.

- Programmable Logic Controller (PLC): The entire line is typically orchestrated by a central PLC. This industrial computer synchronizes the different modules, manages recipes for various cable types and packaging formats, monitors sensor inputs, controls actuators, and provides diagnostic feedback. Operators often interact with the system via a Human-Machine Interface (HMI) touchscreen panel.

Key Technical Specifications to Consider

When evaluating or specifying an automated cable packing line, consider these parameters:

- Cable/Wire Diameter Range: The minimum and maximum diameters the line can handle.

- Finished Coil Dimensions: Target OD, ID, and width/height.

- Maximum Coil Weight: The structural and handling limits of the system.

- Throughput Speed: Required coils per minute or meters/minute.

- Strapping Material & Size: Compatibility with desired strap types.

- Shrink Film Type & Gauge: Suitability for the required protection level.

- Labeling Requirements: Data complexity, print quality, and application needs.

- Power & Air Requirements: Utility consumption.

- Machine Footprint: Physical space needed for installation.

- Control System & Integration: PLC brand preference, communication protocols (e.g., Ethernet/IP, Profinet), and integration with existing factory systems (MES/ERP).

Operational Insights and Experience Sharing

Implementing an automated cable packing line offers significant advantages beyond simple labor reduction:

- Efficiency Gains: Automation drastically reduces cycle times compared to manual methods, often increasing throughput by 2-5x or more, depending on the baseline process. This directly translates to higher production capacity without proportional increases in headcount.

- Consistency and Quality: Automated systems perform tasks identically every time, eliminating human variability. This results in consistent coil dimensions, secure strapping, uniform shrink wrapping, and accurate labeling, reducing product rejects and improving customer satisfaction.

- Reduced Labor Costs: While requiring skilled technicians for operation and maintenance, automation significantly cuts down on the manual labor needed for coiling, handling, strapping, and packing tasks.

- Improved Safety: Automating repetitive and potentially strenuous manual tasks reduces the risk of ergonomic injuries for workers.

- Choosing the Right System: Success depends on carefully matching the line's capabilities to production needs. Over-specifying can lead to unnecessary cost, while under-specifying creates bottlenecks. Factors like production volume, cable fragility, required packaging integrity, and budget are key decision drivers.

- Maintenance: Like any complex machinery, these lines require regular preventative maintenance (lubrication, sensor checks, wear part replacement) to ensure reliability and longevity.

Conclusion

Automated cable packing lines represent a vital technology for modern cable and wire manufacturers and distributors. By integrating coiling, strapping, shrink wrapping, and labeling into a synchronized, PLC-controlled system, businesses can achieve substantial improvements in packaging efficiency, consistency, product protection, and overall operational cost-effectiveness. Careful consideration of technical specifications and operational requirements is crucial for selecting and implementing a system that delivers maximum return on investment and supports sustained growth.