Enhancing Packaging Efficiency: A Closer Look at the A300 Automatic Pallet Wrapping Machine with Film Cutter

In modern manufacturing and logistics environments, efficient and reliable end-of-line packaging is crucial. Consistent pallet wrapping not only protects goods during transit but also optimizes storage and handling. The A300 automatic pallet wrapping machine represents a significant step in automating this process, offering features designed to enhance throughput, reduce labor costs, and improve load integrity. A key component of its automation capabilities is the integrated automatic film cutter.

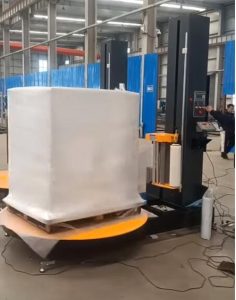

Let's take a look at the machine in action:

1. Understanding the A300's Automated Wrapping Cycle

Unlike semi-automatic wrappers requiring manual film attachment and cutting, the A300 manages the entire stretch wrapping process with minimal operator intervention. A typical cycle involves:

- Pallet Placement: The loaded pallet is positioned onto the turntable via forklift or conveyor.

- Cycle Initiation: The operator starts the wrapping cycle through the control panel or a remote trigger.

- Film Attachment: The machine automatically grips the stretch film and attaches it to the base of the pallet load.

- Wrapping: The turntable rotates while the film carriage moves vertically along the mast, applying the film according to pre-programmed parameters (e.g., number of top/bottom wraps, tension, overlap). Powered pre-stretch systems often stretch the film before application, maximizing film yield and load containment force.

- Film Cutting & Securing: Upon cycle completion, the integrated automatic film Ccutter mechanism cleanly severs the film. Often, a wipe or clamp system then secures the film tail against the load, preventing unraveling.

- Pallet Exit: The wrapped pallet is ready for removal.

pallet stretch wrapping machine with weighing scale 2. The Significance of the Automatic Film Cutter

The automatic film cutter is more than a convenience; it's a core feature driving efficiency and safety:

- Eliminates Manual Cutting: Operators no longer need to manually cut the film with knives, reducing cycle time and removing a potential safety hazard.

- Consistent Results: Automated cutting ensures a clean, reliable sever every time, contributing to a professional-looking wrap.

- Improved Throughput: By automating the final step, the machine is immediately ready for the next pallet, minimizing downtime between cycles.

- Reduced Film Waste: Precise cutting minimizes film tails compared to manual methods.

3. Key Technical Specifications (Typical A300 Model)

While exact specifications can vary, typical parameters for a machine in this class include:

- Turntable Diameter: 1500mm - 1800mm

- Turntable Speed: 3-15 RPM (Adjustable)

- Maximum Load Weight: 1500kg - 2000kg

- Maximum Load Height: 2100mm - 2400mm (Standard, extendable options available)

- Film Carriage: Powered pre-stretch unit (e.g., 200%-300% fixed or variable)

- Control System: PLC (Programmable Logic Controller) with HMI (Human Machine Interface) touch screen

- Power Supply: 220V/380V, 50/60Hz, 3-Phase (Region dependent)

- Film Cut & Clamp/Wipe System: Standard Integrated Feature

- Safety: Safety fencing interlocks, column-mounted emergency stop, under-carriage foot protection sensor (optional)

4. Operational Experience & Practical Considerations

From an operational standpoint, implementing an A300 wrapper brings several considerations:

- Film Selection: Using the correct type, gauge, and quality of stretch film is critical for optimal performance, especially with powered pre-stretch systems. Poor quality film can lead to breaks and inconsistent wrapping.

- Parameter Settings: Fine-tuning wrap parameters (tension, overlap, pre-stretch ratio, number of wraps) via the HMI is essential to achieve desired load containment without crushing the product or wasting film. Different load types may require different recipes.

- Maintenance: Like any automated equipment, routine maintenance is key. This includes cleaning sensors, checking roller conditions, inspecting the film cutter blade sharpness and mechanism, and ensuring the film threading path is clear.

- Operator Training: While highly automated, operators need training on starting/stopping cycles, loading film, selecting programs, and basic troubleshooting (e.g., clearing film jams).

pallet stretch wrap 1 jpg 5. Benefits for Fabricators and Manufacturers

Investing in an automatic wrapper like the A300 offers tangible benefits:

- Labor Savings: Frees up personnel previously dedicated to manual or semi-automatic wrapping for other value-added tasks.

- Improved Load Stability: Consistent application force and wrap patterns significantly reduce product shifting and damage during transit.

- Material Cost Reduction: Powered pre-stretch systems can yield significant film savings compared to manual or lower-end machine wrapping.

- Increased Throughput: Faster, automated cycles allow for higher packaging volumes, crucial for busy production lines.

- Enhanced Safety: Eliminates manual film cutting and reduces operator interaction with moving machinery.

6. Conclusion

The A300 automatic pallet wrapping machine, equipped with an automatic film cutter, provides a robust solution for businesses seeking to enhance their packaging operations. By automating the stretch wrapping process, it delivers improvements in efficiency, consistency, safety, and material usage, contributing directly to a more streamlined and cost-effective logistics chain. Careful consideration of film type, parameter setup, and routine maintenance ensures these benefits are fully realized.

Learn more about automatic pallet wrapping solutions: http://www.fhopepack.com/Stretch_wrapping_machine.html