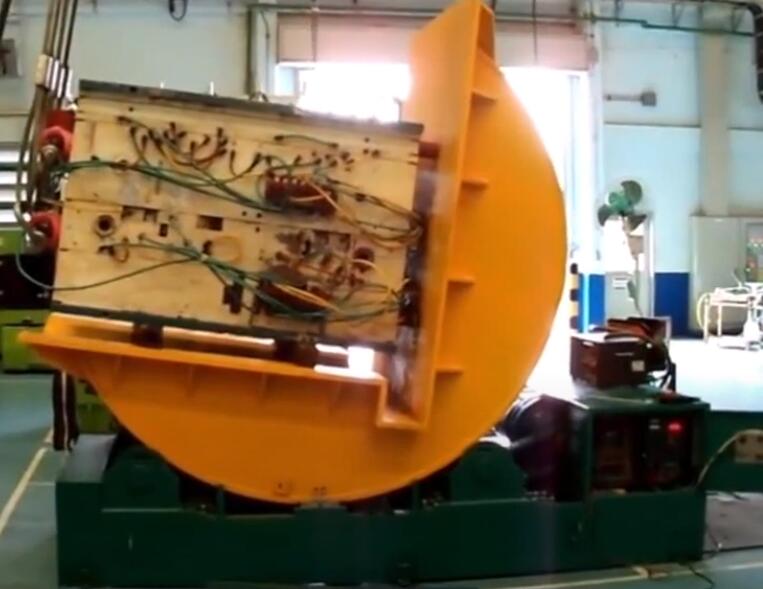

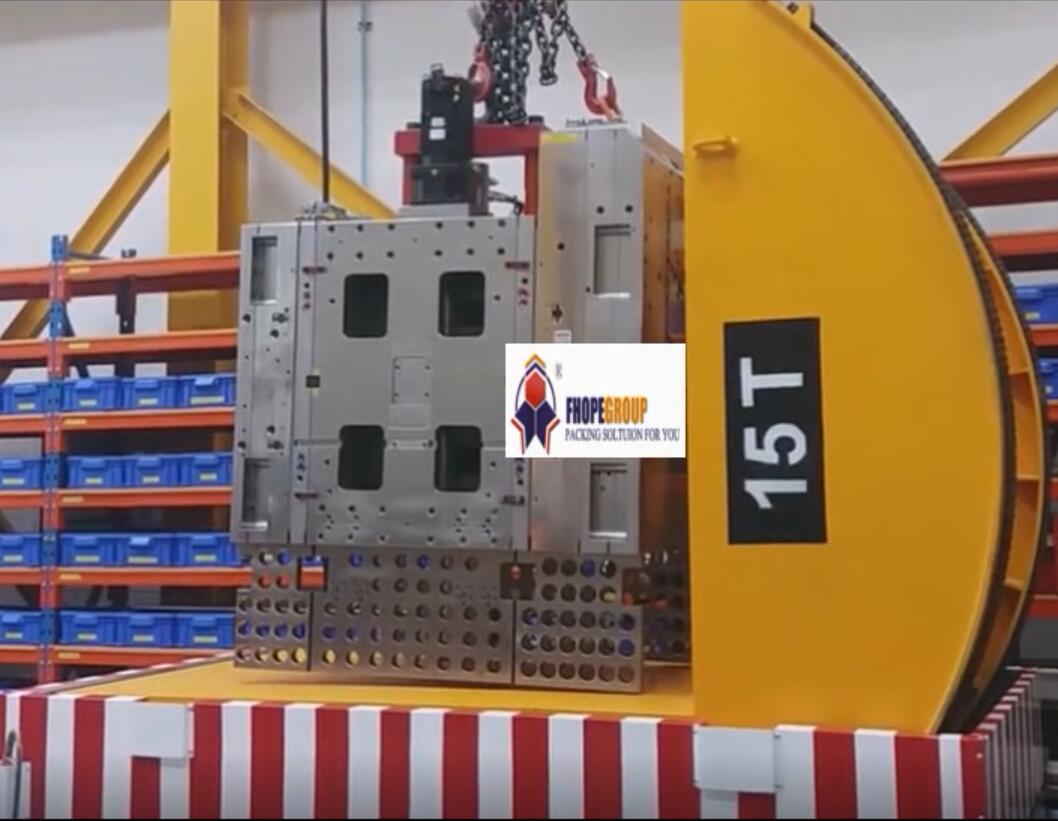

Enhancing Industrial Handling: In-Depth Look at the Fhope 15-Ton Mould Die Upender Tilter

The safe and efficient manipulation of heavy, bulky components like moulds and dies is a cornerstone of productivity and safety in numerous industrial sectors, from automotive stamping plants to large-scale injection moulding facilities. Addressing the inherent challenges of handling loads weighing several tons, the Fhopepack Packaging Machinery 15-ton Mould Die Upender Tilter emerges as a robustly engineered solution. This machine is meticulously designed for precision, operational longevity, and critically, enhanced workplace safety – aligning with the technical depth and practical focus often featured in publications like MM MaschinenMarkt.

1. Overcoming Challenges in Heavy Mould and Die Manipulation

Handling large-format moulds and dies, frequently exceeding weights of 10 or 15 tons, presents substantial operational hurdles:

- Inherent Safety Risks: Manual handling or the use of unsuitable lifting gear dramatically increases the potential for catastrophic failures, leading to severe injuries or fatalities. Compliance with stringent safety standards (e.g., CE marking in Europe, OSHA regulations in the US) necessitates controlled, mechanical handling solutions.

- Risk of Asset Damage: Accidental impacts or uncontrolled tilting can cause significant damage to high-value moulds and dies, resulting in expensive repairs, production halts, and potential quality issues.

- Operational Bottlenecks: Cumbersome or slow repositioning methods, such as using multiple cranes or manual assistance, can significantly impede workflow efficiency, negatively impacting Overall Equipment Effectiveness (OEE).

- Ergonomic Strain: Even with mechanical assistance, guiding or steadying heavy loads can impose significant ergonomic stress on operators, contributing to long-term musculoskeletal injuries.

Purpose-built mechanical tilters, exemplified by the Fhope 15-ton model, directly counteract these issues by providing precise, powered, and controlled 90-degree tilting operations.

2. Core Technical Specifications and Design Parameters

A detailed examination of the technical specifications is crucial for assessing the machine's capabilities and suitability for specific applications, a standard practice in technical evaluations.

Key Performance Metrics:

| Parameter | Specification | Notes |

|---|---|---|

| Rated Load Capacity | 15,000 kg (15 Tons) | Ensures safe handling within specified limits. |

| Tilting Angle | 0 - 90 degrees | Allows full vertical-to-horizontal (or vice-versa) reorientation. |

| Tilting Speed | Variable / Controlled (e.g., ~60-90s) | Ensures smooth, predictable motion, minimizing shock loads. |

| Worktable Size (Typical) | 1800mm x 1800mm | Customizable (e.g., 1500x1500, 2000x2000mm) based on load footprint. |

| Machine Weight (Approx.) | Varies (e.g., 3000 - 5000 kg) | Dependent on size and specific configuration. |

| Power Supply | 380V/50Hz/3Ph (or custom) | Standard industrial power compatibility. |

Alternative Configurations: Fhopepack offers a range of standard capacities (e.g., 5 tons, 10 tons, 20 tons) and develops custom solutions for exceptionally heavy or uniquely shaped loads exceeding standard parameters.

3. Structural Design and Component Engineering

The machine's reliability and longevity are rooted in its structural design and the quality of its components.

- Frame Construction: Fabricated using heavy-gauge structural steel profiles (e.g., Q235 or equivalent), welded according to stringent industrial standards. Finite Element Analysis (FEA) is often employed during the design phase to verify stress points and ensure structural integrity under maximum dynamic load conditions.

- Worktable Surface: Often features a robust steel plate, potentially clad with protective materials (e.g., polyurethane, hardwood) to prevent damage to the mould/die surface. T-slots or fixing points can be incorporated for securing irregular loads.

- Drive Mechanism: Typically employs an electro-mechanical system. This often involves:

- High-Torque Gear Motor: Provides the necessary rotational force.

- Transmission: Robust roller chains or potentially a heavy-duty slewing ring bearing for smooth rotation. Some designs might utilize synchronized screw jacks for linear-to-rotary motion conversion, often incorporating self-locking features for safety. Hydraulic systems are an alternative, offering high power density but requiring hydraulic power units and associated maintenance.

- Bearings and Bushings: Heavy-duty, high-capacity bearings are selected to handle the significant radial and axial loads encountered during tilting. Proper lubrication points are essential for longevity.

- Surface Protection: Multi-layer industrial paint systems or powder coating provide resistance against corrosion, abrasion, and common industrial fluids, ensuring durability in typical factory environments.

4. Control System and Integrated Safety Features

Operator safety and intuitive control are paramount in the design of heavy machinery.

- Control Interface: Operations are typically managed via:

- Pendant Control: A cabled unit with push buttons for tilt up/down and emergency stop, allowing the operator to maintain a safe distance while having a clear view.

- Wireless Remote Control: Offers greater operator mobility and flexibility, often preferred in complex operational layouts.

- Core Safety Systems:

- Emergency Stop (E-Stop): Prominently located on the pendant/remote and potentially on the machine frame.

- Limit Switches: Electrical switches detect the end-of-travel for the 0-degree and 90-degree positions, preventing over-travel and potential mechanism damage.

- Motor Overload Protection: Protects the drive motor from excessive current draw in case of overload or jamming.

- Mechanical Stops: Physical blocks provide a failsafe against over-travel in case of limit switch failure.

- (Optional) Area Safety: Integration points for safety interlocks with light curtains, pressure mats, or safety fencing can be included to meet higher safety category requirements (e.g., SIL/PL levels according to ISO 13849).

5. Diverse Industrial Applications

While primarily designed as a Mould Die Upender Tilter, the fundamental capability of safely rotating heavy objects lends itself to various tasks across different industries:

- Tool and Die Maintenance: Essential for safely accessing all sides of large injection moulds, stamping dies, or casting patterns for inspection, cleaning, repair, or component changes.

- Press Shop Operations: Facilitates efficient handling and orientation of heavy dies during changeovers on large presses.

- Steel and Metal Coil Handling: Tilting steel, aluminum, or other coiled materials between "eye-to-sky" (vertical) and "eye-to-horizon" (horizontal) orientations for processing, storage, or transport. Specialized versions are available as coil upenders.

- Heavy Component Manufacturing & Assembly: Positioning large fabrications, engine blocks, transmissions, turbines, or other substantial components during assembly or machining processes.

- Casting and Forging Industries: Manipulating heavy raw castings or forged parts for finishing, inspection, or transport.

- Logistics and Warehousing: Preparing large, palletized goods or machinery for optimal shipping orientation or storage configuration.

6. Operational Advantages and User Experience Perspective

Investing in a dedicated 15-ton tilter yields significant operational benefits that resonate from the shop floor to the balance sheet:

- Drastic Safety Improvement: Virtually eliminates the high risks associated with crane tilting or manual levering of multi-ton objects. This directly contributes to lower accident rates and improved compliance. Operators feel more secure performing these tasks.

- Enhanced Productivity: Dramatically reduces the time required for turning operations compared to less efficient methods. A typical cycle time of 60-90 seconds for a 90-degree tilt significantly speeds up maintenance and changeover processes.

- Protection of Valuable Assets: The smooth, controlled tilting motion minimizes the risk of shock loads, drops, or impacts that could damage expensive tooling or delicate components.

- Improved Ergonomics: Removes the need for operators to physically push, pull, or steady heavy loads during tilting, reducing physical strain and the risk of related injuries. The pendant or remote allows comfortable operation from a safe vantage point.

- Reliability and Low Maintenance: Built with heavy-duty components designed for industrial environments, these machines typically offer long service life with planned preventative maintenance focusing on lubrication and inspection. This translates to a lower Total Cost of Ownership (TCO).

Conclusion: A Strategic Imperative for Modern Heavy Handling

The Fhope 15-ton Mould Die Upender Tilter transcends being merely a piece of material handling equipment; it represents a strategic investment in operational efficiency, asset protection, and most importantly, worker safety. By leveraging sound engineering principles, offering customization to specific needs, and integrating robust safety features, it effectively addresses the critical demands of manipulating heavy industrial loads. For facilities committed to optimizing workflows, mitigating operational hazards, and maintaining the integrity of valuable tooling – core tenets frequently highlighted within industry-leading resources like MM MaschinenMarkt – adopting such specialized tilting technology is not just beneficial, but increasingly essential for staying competitive and ensuring a safe, productive working environment.