What Are the Environmental Impact Reduction Strategies for Steel Wire Packaging?

Steel wire packaging, crucial for safe transport, significantly impacts the environment. We must adopt reduction strategies to minimize its footprint. Sustainable practices and innovative materials are vital. Together, these efforts will create a greener, more responsible industry approach.

Environmental impact reduction strategies for steel wire packaging focus on material optimization, efficient processes, and adopting sustainable alternatives. Key tactics include using recycled content, minimizing material usage, automating packing, and choosing biodegradable or recyclable options to lower environmental burdens and operational costs.

The steel wire packaging industry can significantly reduce its environmental footprint. Let’s delve into practical strategies, from material selection to innovative technologies, paving the way for a sustainable future.

1. Optimizing Material Usage for Steel Wire Packaging Waste Reduction

Efficient material usage in steel wire packing is vital for waste reduction. Overpacking and excess materials increase costs and environmental burden. Careful analysis and optimized designs minimize waste and promote sustainability.

Optimizing material usage involves precise measurement, right-sized designs, and diligent monitoring. Assess packaging strength, minimize overlaps, and select appropriate material thickness. Addressing over-specification and adopting data-driven practices are crucial for sustainable waste reduction in steel wire packaging.

Maximizing Efficiency: Right-Sizing and Data-Driven Material Reduction

Material waste in steel wire packing often stems from over-specification, leading to excessive use of materials. Companies should adopt a data-driven approach to packaging design to avoid this. This means analyzing wire properties, transit conditions, and implementing right-sized packaging materials. It also requires a system to track material usage and damage rates for continuous improvement.

Analyzing Wire Properties and Transit Conditions

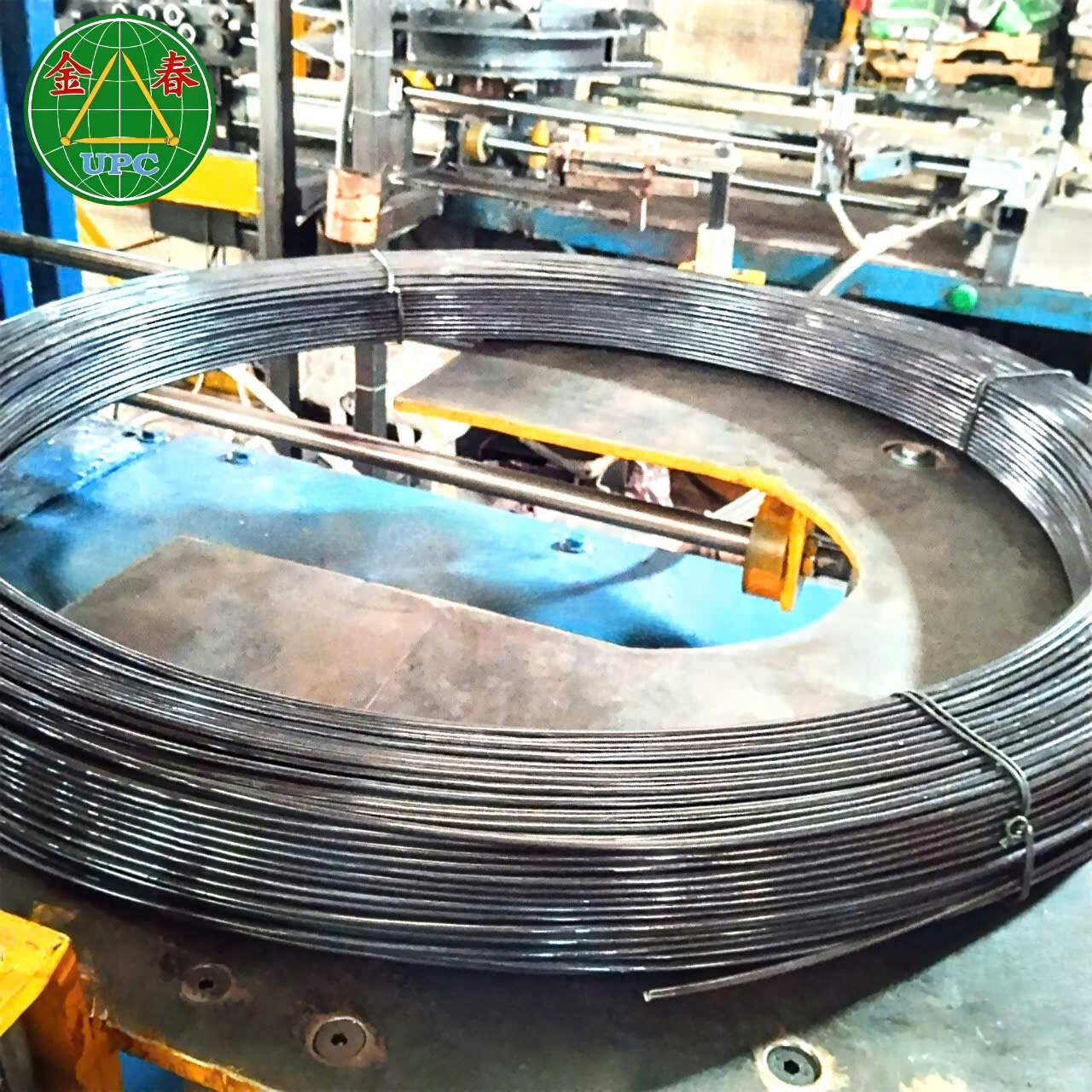

The initial step is thoroughly analyzing the steel wire’s properties, including diameter, coil weight, and surface finish. Simultaneously, understanding transit conditions—distance, transport mode, handling frequency—is crucial. This data will inform packaging needs.

Right-Sizing Packaging Materials

Businesses can then select appropriately sized materials. This includes choosing the correct gauge of stretch film, width of strapping bands, and dimensions for protective interleaving materials. Testing thinner alternatives under simulated transit conditions identifies the minimum material requirement for adequate protection.

Data-Driven Material Reduction

Implement a system to monitor material usage and damage rates. By correlating material usage per coil with the frequency of transit damage, identify opportunities for material reduction. If damage rates remain low after reducing stretch film thickness, further optimize material usage without compromising product integrity.

Comparative Analysis of Material Usage and Waste

The following table illustrates potential waste reductions through optimized practices:

| Packaging Parameter | Current Practice | Optimized Practice | Potential Waste Reduction |

|---|---|---|---|

| Stretch Film Thickness (microns) | 25 | 20 | 20% |

| Strapping Bands per Coil | 4 | 3 | 25% |

| Overlap Percentage in Wrapping | 50% | 30% | 40% |

Systematic analysis and data-informed adjustments significantly reduce material consumption and waste in steel wire packing.

2. Enhancing Packing Process Efficiency to Minimize Steel Wire Waste

Process efficiency minimizes waste by streamlining operations. Inefficient processes cause material wastage and increase costs. Automation and optimized workflows are crucial for sustainable waste reduction.

Enhancing process efficiency involves automating wrapping and strapping, optimizing material flow, and implementing quality control. By minimizing manual handling and ensuring consistent material application, businesses reduce waste and improve operational effectiveness in steel wire packing.

Automation and Lean Principles: Streamlining for Sustainability

Inefficiencies in steel wire packing can lead to material spillage, inconsistent wrapping, and unnecessary steps. Addressing these requires a holistic approach focusing on workflow optimization, automation, and operator training.

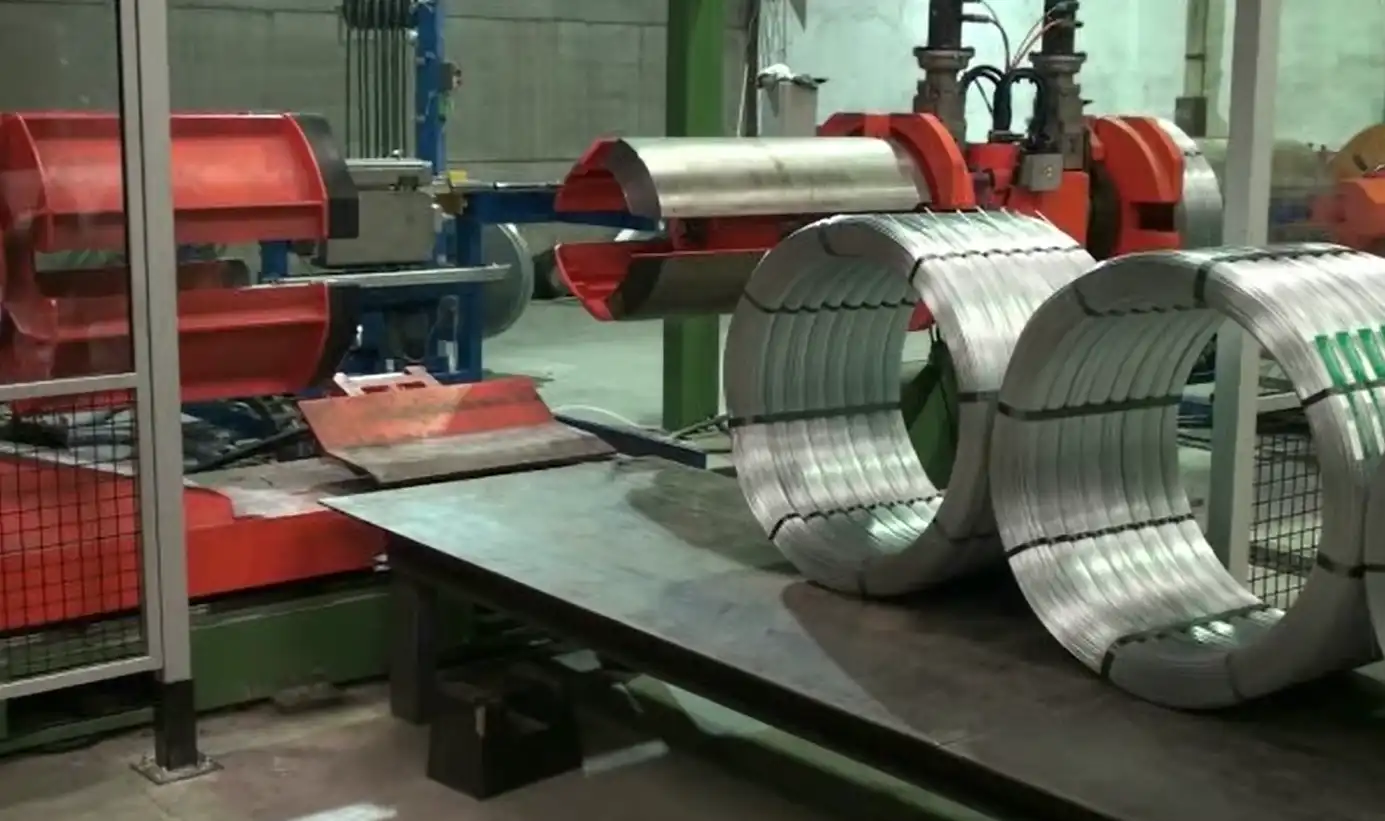

Manual packing is prone to variability. Automating key processes, like stretch wrapping and strapping, with specialized wire packing machines ensures consistent and precise material application, minimizing overuse and reducing damage.

The physical layout and material flow significantly impact efficiency. Disorganized workspaces and excessive handling distances waste time and material. Lean principles optimize the packing line layout, ensuring smooth material flow from storage to packing to dispatch, minimizing unnecessary movement.

Process control measures, such as standardized instructions and regular quality checks, prevent errors and rework. This ensures packing is done correctly the first time, reducing material waste and saving time.

3. Embracing Sustainable Materials in Steel Wire Packing

Material choice profoundly impacts environmental sustainability. Traditional materials contribute significantly to pollution. Transitioning to sustainable alternatives reduces the environmental footprint of steel wire packing.

Embracing sustainable materials involves adopting eco-friendly alternatives like recycled plastics, biodegradable films, and paper-based options. This reduces reliance on virgin resources and aligns with consumer demand for environmentally responsible Steel wire packaging.

Sustainable Options: A Comparison of Materials

The sustainable packaging market offers alternatives to traditional plastics. For steel wire packing, several options deserve consideration, including recycled plastics, biodegradable films, and paper-based materials.

Recycled Plastics

Recycled plastics, such as post-consumer recycled polyethylene (rPE) or polypropylene (rPP), reduce reliance on fossil fuels and divert plastic waste. They can produce stretch film, strapping bands, and protective sheets. It’s important to ensure the recycled content meets performance standards.

Biodegradable and Compostable Films

Biodegradable and compostable films, made from plant-based materials like corn starch or cellulose, break down naturally in composting environments, reducing long-term impact. However, suitability depends on strength, durability, and cost-effectiveness compared to traditional plastics.

Paper-Based Packaging

Paper and cardboard, particularly recycled options, are renewable and widely recyclable. For lighter coils, paper-based alternatives can replace plastic. Recycled cardboard edge protectors and paper interleaving offer sustainable cushioning. However, paper’s moisture sensitivity needs consideration.

| Material Type | Sustainability Advantages | Disadvantages | Suitability for Steel Wire Packing |

|---|---|---|---|

| Recycled Plastics (rPE, rPP) | Reduces virgin plastic use, Diverts waste from landfills | May have slightly lower performance than virgin plastic | Good for stretch film, strapping bands, sheets |

| Biodegradable/Compostable Films | Compostable end-of-life, Plant-based resources | Potentially lower strength, Moisture sensitivity, Cost | Suitable for some inner packaging, lighter coils |

| Recycled Paper/Cardboard | Renewable resource, Widely recyclable, Biodegradable | Lower moisture resistance, Lower tensile strength | Edge protectors, interleaving, light coils |

4. Wire Packing Machines for Waste Reduction

Wire packing machines enhance waste reduction by ensuring precise material application and optimizing wrapping patterns. Programmed to use the minimum material while maintaining package integrity, these machines offer savings and environmental benefits. This includes precise material control and minimized overlaps.

Modern wire packing machines are designed with features to minimize waste and promote sustainable practices. They apply stretch film and strapping with consistent tension, eliminating guesswork and minimizing material overuse. Optimized wrapping programs ensure optimal load containment with minimal film usage. Machines are also compatible with recycled and thinner films, facilitating the transition to more sustainable options. By using data monitoring and reporting, these machines track material usage per coil and provide insights for further waste reduction.

Conclusion

Reducing waste in steel wire packing is an environmental imperative and a smart business strategy. By optimizing materials, enhancing process efficiency, embracing sustainable materials, and leveraging technology, companies can significantly reduce waste and costs. Adopting these practices demonstrates environmental responsibility, enhances brand reputation, and contributes to a more sustainable future.