What Are the Benefits of Using PPR Pipe Bundling Machines?

PPR pipe bundling machines are revolutionizing the plastic pipe industry. These machines automate the process of bundling, packing, and strapping PPR pipes, leading to significant improvements in efficiency, cost savings, and product quality.

PPR pipe bundling machines offer numerous benefits, including reduced labor costs, increased packaging accuracy, improved automation, and enhanced protection of PPR pipes. These advantages contribute to a more efficient and reliable pipe production process.

Are you ready to streamline your PPR pipe production and packaging processes? Let’s delve into the myriad advantages of using PPR pipe bundling machines and explore how they can transform your operations.

Automation and Efficiency in PPR Pipe Packaging

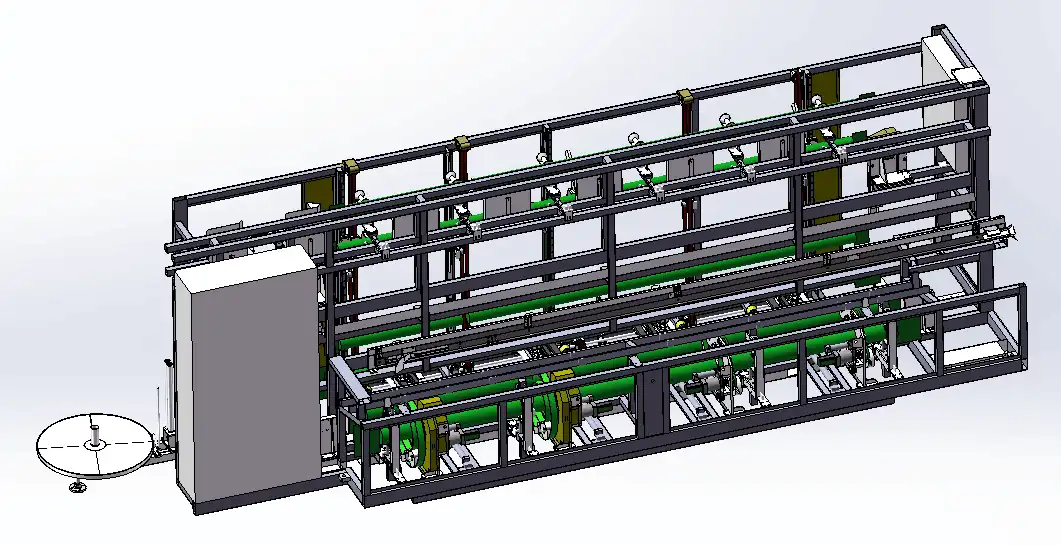

Automatic PPR pipe bundling machines are designed to increase efficiency. They are connected to the production equipment to achieve a seamless workflow. It can automatically sense and identify the length and specifications of the pipe, bundle and seal according to the set parameters, ensuring the firmness and aesthetics of the packaging.

Automatic PPR pipe bundling machines significantly enhance packaging efficiency by automating the process of bundling, strapping, and wrapping pipes. This reduces manual labor, minimizes errors, and accelerates production, leading to substantial cost savings and improved output.

But how do these machines achieve such remarkable efficiency gains? Let’s examine the specific features and functionalities that make them indispensable in modern PPR pipe production facilities.

Streamlining Operations: Key Features of PPR Pipe Bundling Machines

PPR pipe bundling machines are not one-size-fits-all. They come in various models with different features and capabilities, each designed to address specific needs and challenges in the pipe packaging process. Understanding these features is crucial for selecting the right machine for your operations.

1. Automatic Counting and Feeding Systems

These systems accurately count and feed pipes into the bundling station, eliminating manual counting errors and ensuring consistent bundle sizes. They often incorporate sensors and programmable logic controllers (PLCs) to ensure precise operation.

2. Bundling and Strapping Mechanisms

These mechanisms securely bundle the pipes and apply straps or wrapping materials to hold them together. They can be adjusted to accommodate different pipe diameters and bundle sizes.

3. Wrapping and Sealing Stations

These stations wrap the bundled pipes in protective materials such as PE film or woven bags, sealing them to prevent damage during transportation and storage.

4. Automatic Stacking and Palletizing Systems

These systems automatically stack and palletize the bundled pipes, further streamlining the packaging process and reducing the need for manual handling.

Comparing Manual vs. Automated PPR Pipe Packaging

To fully appreciate the benefits of PPR pipe bundling machines, it’s helpful to compare them to traditional manual packaging methods. The following table highlights the key differences:

| Feature | Manual Packaging | Automated Packaging |

|---|---|---|

| Efficiency | Low | High |

| Labor Costs | High | Low |

| Accuracy | Low | High |

| Consistency | Low | High |

| Material Waste | High | Low |

| Safety | Lower | Higher |

As the table illustrates, automated packaging offers significant advantages over manual methods in terms of efficiency, cost, accuracy, consistency, material waste, and safety.

Choosing the Right PPR Pipe Bundling Machine

Selecting the right PPR pipe bundling machine depends on several factors, including:

- Production volume: Higher production volumes may require more sophisticated and automated machines.

- Pipe diameter and length: The machine should be able to accommodate the range of pipe sizes you produce.

- Packaging requirements: Consider the type of packaging material you need (e.g., PE film, woven bags) and the level of protection required.

- Budget: PPR pipe bundling machines can range in price from a few thousand dollars to hundreds of thousands of dollars.

By carefully considering these factors, you can choose a machine that meets your specific needs and budget.

Enhancing Product Quality and Reducing Damage

PPR pipe is often used for household hot water pipe, so it has high requirements on the surface of PPR pipe. Therefore, packing the pipe can effectively protect the pipe. Using automatic bundling and packing machine for pipe can effectively reduce labor, reduce labor costs, automated production.

PPR pipe bundling machines protect pipes from damage during handling, transportation, and storage. By providing secure bundling and wrapping, these machines minimize the risk of scratches, dents, and other forms of damage, ensuring that the pipes arrive at their destination in pristine condition.

How Bundling Machines Minimize Damage

- Secure Bundling: Pipes are tightly bundled together, preventing them from shifting and rubbing against each other during transportation.

- Protective Wrapping: Wrapping materials such as PE film or woven bags provide a barrier against external elements and physical impacts.

- Proper Handling: Automated handling systems reduce the risk of dropping or mishandling the pipes.

Cost Savings and ROI of PPR Pipe Bundling Machines

PPR pipe bundling machines offer a compelling return on investment (ROI) by reducing labor costs, minimizing material waste, and improving production efficiency. These cost savings can quickly offset the initial investment in the machine.

The primary sources of cost savings with PPR pipe bundling machines include reduced labor costs due to automation, minimized material waste from precise packaging, and increased production throughput, leading to a faster ROI and improved profitability.

Let’s break down the key areas where these machines deliver significant cost advantages.

Quantifying the Cost Benefits

1. Labor Cost Reduction

One of the most significant cost savings comes from reduced labor requirements. By automating the bundling and packaging process, businesses can significantly reduce the number of workers needed, resulting in substantial savings on wages and benefits.

2. Material Waste Reduction

Manual packaging often leads to material waste due to inconsistent wrapping and sealing. PPR pipe bundling machines, on the other hand, ensure precise and consistent packaging, minimizing material waste and saving money on packaging supplies.

3. Increased Production Throughput

Automated packaging significantly increases production throughput compared to manual methods. This means businesses can produce more pipes in less time, leading to increased revenue and profitability.

Calculating ROI

To estimate the ROI of a PPR pipe bundling machine, consider the following factors:

- Initial investment: The cost of the machine, including installation and training.

- Labor savings: The annual savings in labor costs due to automation.

- Material savings: The annual savings in material costs due to reduced waste.

- Increased revenue: The annual increase in revenue due to increased production throughput.

- Maintenance costs: The annual costs of maintaining the machine.

Using these factors, you can calculate the payback period and the overall ROI of the machine.

Real-World Examples

Many PPR pipe manufacturers have already experienced the benefits of using PPR pipe bundling machines. For example, one manufacturer reported a 50% reduction in labor costs and a 20% increase in production throughput after implementing an automated bundling system.

Types of PPR Pipe Bundling Machines

Automatic pipe capping machine is a vital component of an automatic online pipe packing line. It can seamlessly connect to an extrusion machine for streamlined online packing operations.

Automatic pipe capping machine be designed to cap pipes with efficiency and precision. It is specifically designed for pipe diameters ranging from 20 to 32. However, customization options are available to accommodate other diameter specifications.

A full-automatic pipe bundling and bagging machine be a vital component of an automatic online pipe packaging solutions. It can seamlessly connect to an extrusion machine for streamlined online packing operations.

Conclusion

PPR pipe bundling machines offer a wide range of benefits, including increased efficiency, reduced costs, improved product quality, and enhanced safety. By automating the packaging process, these machines can help businesses streamline their operations, reduce waste, and increase profitability. If you’re looking for a way to improve your PPR pipe production process, consider investing in a PPR pipe bundling machine.