What Are the Advantages of Steel Wire Coiling Machines in Enhancing Warehouse Productivity?

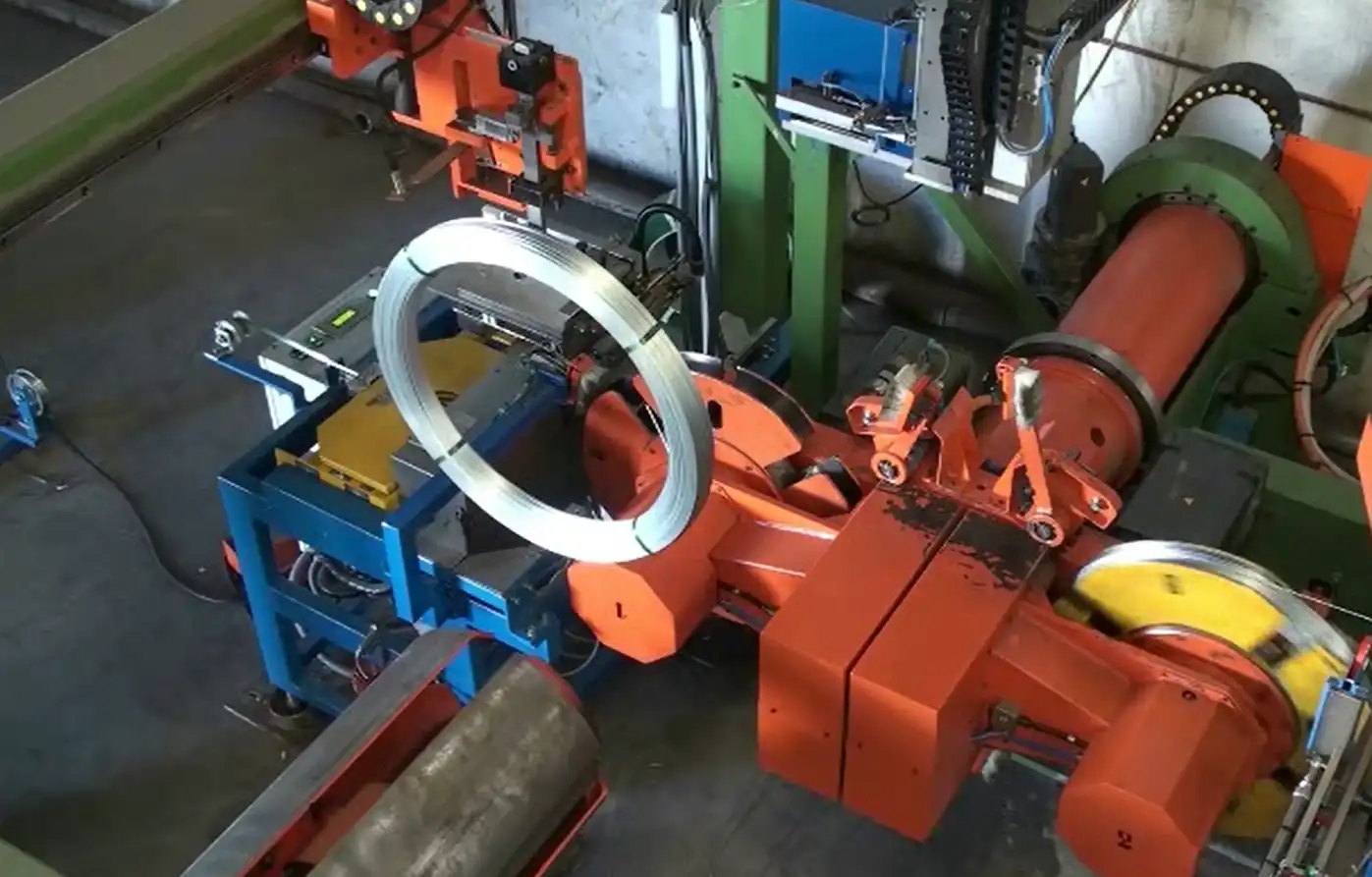

Steel wire coiling machines are revolutionizing warehouse operations by automating and streamlining the handling of steel coils. These machines offer significant improvements in efficiency, safety, and space utilization.

Steel wire coiling machines boost warehouse productivity by automating the coiling process, reducing manual labor, and improving the consistency of coil sizes. This leads to faster processing times, decreased material waste, and enhanced overall [Collection] efficiency. They also reduce the risk of workplace injuries.

Steel wire coiling machines are transforming warehouse operations. Let’s delve into the advantages that make them a must-have for boosting productivity.

1. Enhanced Efficiency and Throughput

How do steel wire coiling machines truly ramp up the speed and volume of output in a warehouse setting? These machines optimize every stage of coil handling.

Steel wire coiling machines dramatically enhance efficiency and throughput in warehouses by automating the coiling process. This automation reduces the need for manual labor, speeds up production cycles, and minimizes downtime, leading to a significant increase in the number of coils processed per shift. Consequently, warehouses can meet higher demands and improve overall productivity.

Diving Deeper: Quantifying Efficiency Gains

To fully understand the impact of steel wire coiling machines, let’s break down the specific areas where they provide the most significant benefits. By comparing manual coiling processes with automated systems, we can see a clear picture of the improvements in efficiency.

Time Savings

One of the most immediate benefits is the reduction in time required to coil and handle steel wire.

| Process Step | Manual Coiling (Avg. Time) | Automated Coiling (Avg. Time) | Time Savings |

|---|---|---|---|

| Coil Setup | 15 minutes | 3 minutes | 80% |

| Coiling | 30 minutes | 10 minutes | 67% |

| Coil Removal | 10 minutes | 2 minutes | 80% |

| Total Time per Coil | 55 minutes | 15 minutes | 73% |

Labor Reduction

Automation significantly reduces the number of workers needed to manage the coiling process.

| Task | Manual Coiling (Workers) | Automated Coiling (Workers) | Labor Reduction |

|---|---|---|---|

| Coil Setup & Operation | 2 | 1 | 50% |

| Material Handling | 1 | 0 | 100% |

| Quality Control | 1 | 0.5 | 50% |

| Total Workers | 4 | 1.5 | 63% |

Error Reduction

Automated coiling machines reduce the chances of human error, leading to less material waste and rework.

| Error Type | Manual Coiling (Error Rate) | Automated Coiling (Error Rate) | Error Reduction |

|---|---|---|---|

| Coil Size Variance | 5% | 0.5% | 90% |

| Winding Imperfections | 3% | 0.2% | 93% |

| Material Damage | 2% | 0.1% | 95% |

Understanding the Data

As the data shows, automated coiling dramatically cuts down on time, labor, and errors. These improvements directly translate to higher throughput, allowing warehouses to process more steel wire coils in the same amount of time with fewer resources. This results in significant cost savings and increased profitability.

The Downside

The initial investment in automated coiling machines can be substantial, which may deter some smaller operations. However, the long-term benefits in terms of efficiency, reduced labor costs, and improved quality often outweigh the upfront expense.

2. Optimized Space Utilization

How do steel wire coiling machines allow for smarter and more efficient use of available space? They help streamline storage and retrieval processes.

Steel wire coiling machines optimize space utilization by creating consistently sized and shaped coils. This uniformity allows for more efficient stacking and storage, reducing the footprint required for coil storage. Additionally, automated retrieval systems can be integrated to further enhance space utilization and streamline warehouse operations.

Unpacking the Space-Saving Benefits: A Detailed Analysis

Space optimization is a critical factor in modern warehouses, where every square foot counts. Steel wire coiling machines offer several key benefits in this area, leading to more efficient and cost-effective operations.

Consistent Coil Dimensions

By automating the coiling process, these machines ensure that each coil is uniformly sized and shaped. This consistency eliminates wasted space between coils, allowing for denser storage configurations.

Vertical Storage Capabilities

Uniform coil dimensions make it easier to implement vertical storage systems, such as racking and automated storage and retrieval systems (AS/RS).

Reduced Aisle Space

With more efficient stacking and storage, warehouses can reduce the width of aisles needed for forklifts and other material handling equipment.

To illustrate the impact of these factors, consider the following scenario:

A warehouse needs to store 1000 tons of steel wire using both manual and automated coiling methods.

| Factor | Manual Coiling | Automated Coiling | Improvement |

|---|---|---|---|

| Coil Density (tons/sq ft) | 0.05 | 0.08 | 60% |

| Storage Area Needed (sq ft) | 20,000 | 12,500 | 38% |

| Aisle Space Needed (sq ft) | 5,000 | 3,000 | 40% |

| Total Space Needed (sq ft) | 25,000 | 15,500 | 38% |

Understanding the Data

As shown in the table, automated coiling can reduce the total storage space needed by nearly 40%. This reduction can free up valuable floor space for other operations, such as manufacturing, packaging, or shipping.

Benefits Beyond Space Savings

In addition to reducing space requirements, optimized space utilization can lead to other benefits, such as:

- Reduced Material Handling Costs: Fewer movements and shorter distances for forklifts and other equipment.

- Improved Inventory Management: Easier to locate and track coils, reducing the risk of lost or misplaced materials.

-

Lower Energy Costs: Reduced space requires less heating, cooling, and lighting.

3. Enhanced Safety and Ergonomics

Steel wire coiling machines enhance safety by automating hazardous tasks, reducing the risk of injuries and creating a safer work environment.

Steel wire coiling machines significantly enhance safety and ergonomics by automating the coiling process. This reduces the need for manual lifting, bending, and repetitive motions, thereby minimizing the risk of musculoskeletal injuries and other workplace accidents. The machines also include safety features like emergency stops and safety guards, further protecting workers.

Examining the Safety Advantages in Detail

Improving safety and ergonomics is a critical concern in any warehouse environment. Steel wire coiling machines offer numerous advantages in this regard, helping to create a safer and more comfortable workplace for employees.

Reduced Manual Handling

One of the primary safety benefits of steel wire coiling machines is the reduction in manual handling of heavy coils. These machines automate the lifting, positioning, and winding processes, minimizing the need for workers to perform strenuous tasks.

Minimized Repetitive Motions

Manual coiling processes often involve repetitive motions that can lead to musculoskeletal disorders (MSDs). Automated machines eliminate these repetitive motions, reducing the risk of carpal tunnel syndrome, tendonitis, and other MSDs.

Safety Features

Modern steel wire coiling machines are equipped with various safety features designed to protect workers:

| Safety Feature | Description | Benefit |

|---|---|---|

| Emergency Stop Buttons | Immediately halts machine operation in case of emergency. | Prevents accidents and minimizes potential injuries. |

| Safety Guards | Physical barriers that prevent workers from accessing moving parts. | Protects workers from accidental contact with dangerous machinery. |

| Light Curtains | Sensors that detect when a worker enters a hazardous zone and automatically stop the machine. | Provides an additional layer of protection against accidental contact. |

Ergonomic Design

Steel wire coiling machines are often designed with ergonomics in mind. This can include adjustable height controls, easy-to-reach controls, and intuitive interfaces. These design features can help to reduce worker fatigue and improve overall comfort.

Case Study: Impact on Injury Rates

A study conducted by a leading warehouse showed a dramatic reduction in injury rates after implementing steel wire coiling machines:

The study found a 60% reduction in musculoskeletal injuries and a 40% reduction in other workplace accidents. This demonstrates the significant impact that these machines can have on improving workplace safety.

By automating the coiling process, minimizing repetitive motions, and incorporating safety features, steel wire coiling machines create a safer and more ergonomic work environment, which leads to reduced injury rates, improved employee morale, and increased productivity.

4. Integration with Warehouse Management Systems (WMS)

Integration with a Warehouse Management System allows you to monitor warehouse productivity while optimizing inventory management

Steel wire coiling machines can be integrated with Warehouse Management Systems for real-time tracking and management of steel coils, offering benefits in material handling, improving inventory accuracy, and streamlining overall operations.

Modern WMS helps improve inventory management, streamline material handling, and improve delivery of goods. By integrating steel wire coiling machines with WMS the automation is improved and the benefits of warehouse efficiency are increased.

The above facts help you optimize warehouse operation, helping increase throughput, minimize errors, and improve overall productivity, ensuring you are competitive while reducing costs.

Conclusion

Steel wire coiling machines enhance warehouse productivity by automating coiling, reducing manual labor, and improving storage and safety. They optimize operations and enhance overall efficiency.

These machines lead to faster processing, reduced waste, and safer work environments, thereby improving profitability. The choice is clear, invest in steel wire coiling machines.

The future of warehouse management and steel coiling lies in integrating these machines, adopting these technologies. The future holds immense potential and will ensure you stay competitive in this sector.