FHOPEPACK’s advanced coil upenders provide efficient solutions for heavy steel coil handling, ensuring safety and reducing downtime in your production line. Experience seamless operations with our innovative equipment designed for industrial resilience.

Heavy-duty coil upenders excel in safely handling and rotating steel coils, vital for efficient manufacturing processes. Their robust design ensures the stability and adaptability required for demanding operations, enhancing productivity while minimizing risks in steel coil management.

In our quest for efficiency, FHOPEPACK has revolutionized the coil handling scenarios by introducing specialized solutions that not only meet but exceed industry standards. Our focus remains on integrating safety and speed into industrial workflows.

1. What Are Heavy Duty Coil Upenders?

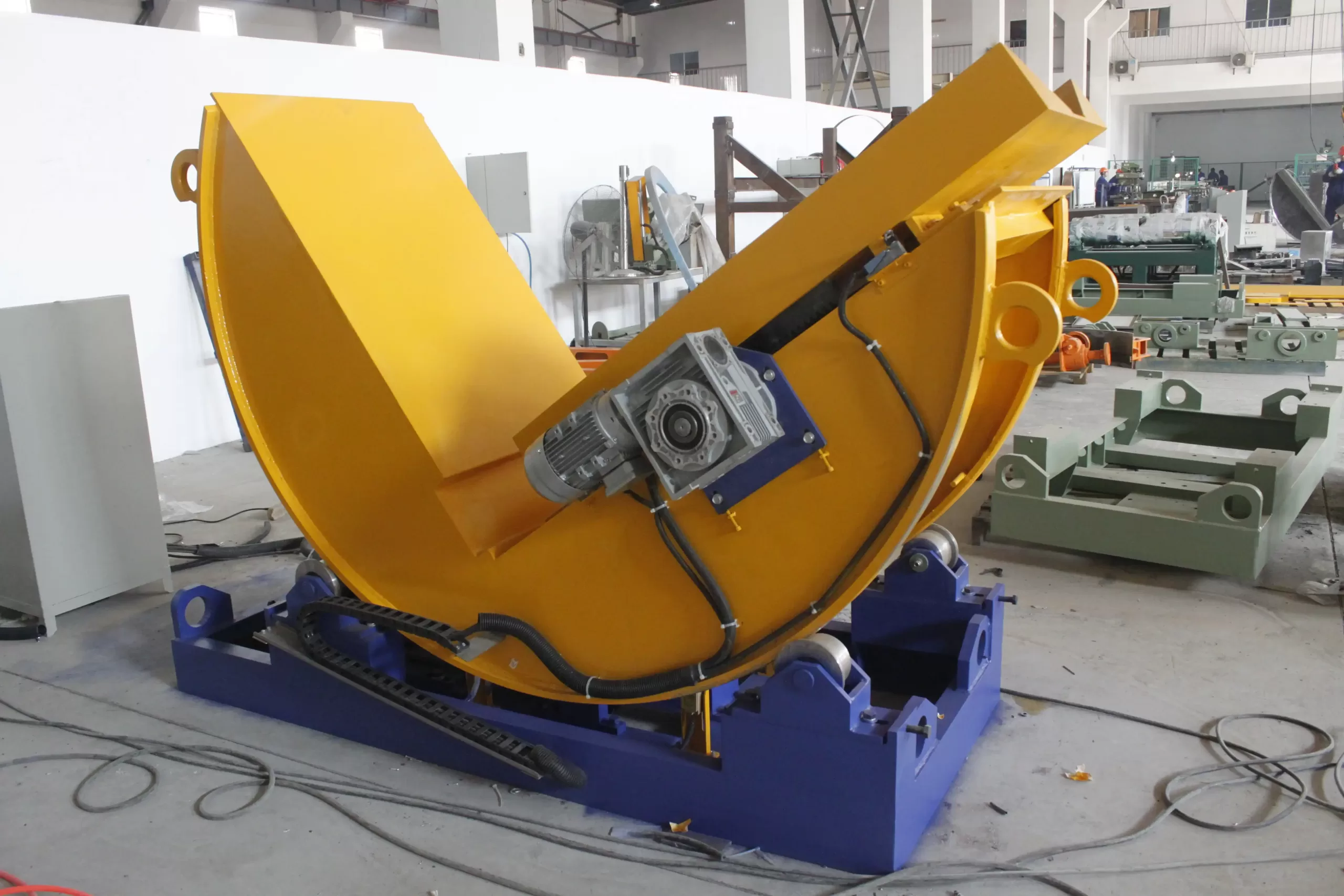

Heavy-duty coil upenders provide solutions for rotating heavy steel coils seamlessly. They are indispensable in industries where coils need repositioning for further processing. By mitigating manual handling risks, these machines increase safety and efficiency.

Coil upenders are machines designed to safely rotate large and heavy steel coils. Their main function is to reposition coils from vertical to horizontal orientations or vice versa, ensuring smooth transitions in production lines. These machines enhance workflow efficiency and adhere to stringent safety standards.

Digging Deeper into Coil Upender Features

Understanding the features of coil upenders can shed light on their benefits and possible applications in industrial settings. These machines extend beyond mere rotation, offering advanced functionality that contributes to operational efficiency.

| Feature | Description | Benefit |

|---|---|---|

| Load Capacity | Can handle loads up to several tons | Reduces manual handling |

| Rotation Mechanism | Hydraulic or electric systems provide smooth transitions | Ensures steady coil rotation |

| Control Systems | Advanced controls for precision and safety | Enhances operational accuracy |

| Customization | Adaptable designs for various coil sizes and weights | Increases versatility and utility |

Coil upenders are engineered with robust materials that ensure longevity even under rigorous use. The choice between hydraulic and electric rotation mechanisms depends on specific operational requirements. Hydraulic systems offer a more forceful reach, making them suitable for heavier coils. Electric systems, while typically quieter, provide precise control, which is ideal for operations requiring delicate handling.

As a mechanical engineer with years of experience in the packaging industry, I have seen how integrating these machines leads to significant time and cost savings. They efficiently reduce the dependency on manual labor, which decreases fatigue and potential injuries among workers.

By selecting the right coil upender, businesses not only meet their safety and efficiency needs but also gain an edge in optimizing their production lines. With these insights, it becomes apparent that adopting advanced coil handling technologies is not just beneficial but integral to modern industry success.

2. How to Choose the Right Coil Upender for Your Needs?

Efficiency matters, especially in packaging. Choosing the right coil upender can revolutionize handling, bringing order and safety to your production ecosystem, saving both time and costs.

Selecting the right coil upender involves considering the weight and dimensions of your coils, operational capacity, and safety features. Tailor your choice to meet specific operational requirements for optimal performance.

Breaking Down Coil Upender Selection:

Choosing the right coil upender is more than just matching capacity with weight. It’s about understanding your production needs and the technicalities behind these machines. Let’s examine three key considerations to guide your decision:

-

Coil Specifications: Criteria Importance Example Weight Capacity Must handle the heaviest coil Up to 30,000 lbs Coil Dimensions Fit dimensions precisely Customizable options Safety Features Critical for manual operations Emergency stop capabilities Coil specifications should be thoroughly assessed. Misalignment in weight or size can disrupt operations and incur costs.

-

Operational Capacity: Criteria Importance Example Frequency of Usage Dictates durability needs High-frequency for large ops Versatility Handles various coil types Rotational and tilting features Integration Compatibility with existing lines Modular integration options Ensure the upender can handle your operational load without breaking down. Versatility in handling different coil types also adds value to your investment.

-

Automation and Technology: Criteria Importance Example Control Systems Advanced for precision and safety PLC-controlled systems Connectivity Integrates with modern industrial IoT systems Remote monitoring capabilities Consistency Supports consistent throughput Reduced human error Modern technology can streamline operations, increasing productivity and reducing operational hiccups. Consider the tech capacity when choosing an upender.

3. What Are the Top Models of Heavy Duty Coil Upenders?

When heavy lifting is daily, the choice of coil upender can make or break operational efficiency. A well-chosen model promises safety and swift handling.

Top models of heavy-duty coil upenders feature robust construction, high load capacity, and advanced operational controls. They ensure safety and efficiency in handling heavy steel coils.

Top Choices in Heavy Duty Coil Upenders:

Not all coil upenders are created equal, so understanding the strengths of various models can save time and resources. Here’s a deeper dive into some leading models:

-

X-Series Heavy Duty Upenders: Feature Benefit Detail Load Capacity High – up to 50,000 lbs Ideal for large-scale industrial use Construction Durable steel structure Long lifespan with minimal maintenance Control System Intuitive touch-screen control User-friendly interface The X-Series is known for its durability and ease of use, fitting diverse operational environments.

-

Y-Pro Coil Upender Range: Feature Benefit Detail Precision Handling Reduces coil damage Smooth and controlled movement Multi-functionality Combines lifting and turning actions Versatile for different operations Safety Features Advanced safety protocols Ensures operator safety Y-Pro models excel in precision and safety, providing reliable performance under demanding conditions.

-

Z-Force Industrial Upender: Feature Benefit Detail High Customizability Tailors to specific client needs Custom design options available Sturdiness Can endure harsh industrial settings Built tough for extreme environments Integration Seamless with existing systems Supports existing frameworks The Z-Force series is a go-to for tailored solutions, adapting well to specific operational environments.

Conclusion

Choosing the right heavy-duty coil upender is essential for enhancing efficiency and safety in handling steel coils. The correct model streamlines operations and prevents delays, aligning with your production’s specific needs. Prioritize key features and tailor your choice for the utmost safety and productivity.

Summarize the key points on heavy-duty coil upenders and emphasize the importance of selecting the right model to enhance efficiency and safety in handling steel coils.