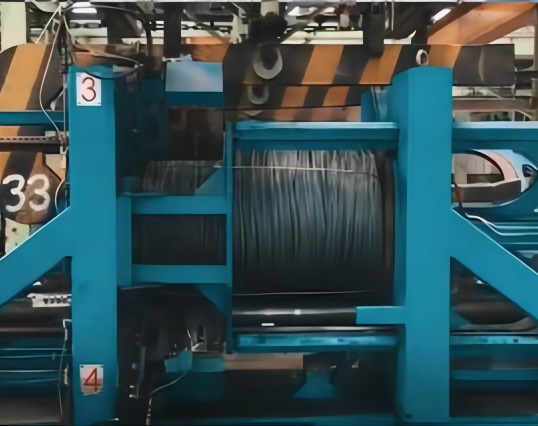

Steel Wire Coil Packing Lines: How to Provide Customized Solutions for Small and Medium Businesses?

Small and medium businesses often face challenges that big manufacturers don’t. When it comes to coil packing, they struggle with limited budgets, tight spaces, and diverse product sizes.

Customized steel wire coil packing lines can solve these problems. Tailored systems improve efficiency, save space, and cut labor costs without requiring massive investments.

These businesses don’t need oversized, generic systems. They need practical, scalable solutions. Below, I’ll explain how I help customers find the right machine, one that fits their needs and space.

What Are the Common Challenges Faced by Small and Medium Manufacturers?

For many small and mid-sized companies, packaging lines are often an afterthought. Space, budget, and labor constraints get in the way of automation.

Many small businesses struggle with irregular coil sizes, changing orders, and limited staff. They need machines that are easy to adjust, operate, and maintain, without high training costs.

Matching Machine Flexibility with Production Needs

Custom solutions start by listening. When I design a system for a client, I ask what kinds of coils they pack daily. Some clients switch between 5–10 coil sizes in one day. That’s a real challenge.

I avoid fixed-dimension machines in such cases. Instead, I propose adjustable conveyors, modular wrapping stations, and semi-auto options that can later upgrade to full automation.

This kind of flexibility allows businesses to start small and scale up. Here’s how I match needs with solutions:

| Challenge | Custom Approach |

|---|---|

| Small workshop space | Compact L-shape or U-shape layout |

| Multiple coil sizes | Adjustable wrapping ring & tension system |

| Low manpower | Auto loading with simple HMI controls |

| Budget limitations | Semi-auto models with upgrade paths |

A fixed machine won’t work if your products change every week. That’s why small businesses need adaptive machines—not just cheap ones.

How Do Custom Coil Packing Lines Improve Production Efficiency?

Automation sounds expensive. But in reality, smart automation can save time and money. Even for smaller operations.

The right packing line can double output and cut labor by half. That’s not theory—I’ve seen it in action at client sites.

Eliminating Downtime with Tailored Machine Layouts

A standard machine may require constant manual feeding and realignment. That creates downtime. I customize layout designs so that operators can run the line without stopping.

In one project, I helped a customer build a packing line in a narrow warehouse. We used a space-saving vertical wrapping station with side infeed and an inline strapping unit. This cut idle time between wrapping and strapping.

Let’s compare:

| Setup Element | Standard Line | Customized Line for SMBs |

|---|---|---|

| Feeding system | Manual coil pushing | Motorized V-shaped infeed rollers |

| Wrapping ring | Fixed-size | Adjustable with smart tensioning |

| Strapping station | Manual placement | Sensor-triggered auto positioning |

| Final unloading | Manual | Pneumatic arm + turntable |

By reducing waiting time at each stage, a 2-man team can now do the job of 5. That’s how real efficiency starts—from the design.

What Factors Should Be Considered Before Choosing a Custom Solution?

Small manufacturers often rush into buying machines without understanding their needs. That leads to mismatches and frustration.

You don’t need the biggest or most high-tech system. You need one that fits your product, space, and workflow.

Checklist to Match the Right Machine to Your Business

Before I give any proposal, I ask my clients 3 key things:

- What is the size range of your coils?

- How many coils do you pack per shift?

- What are the current pain points in your process?

Based on that, I determine the core machine type, automation level, and optional add-ons. I don’t upsell—I configure.

Here’s a simplified checklist I use when guiding clients:

| Evaluation Item | Details Needed |

|---|---|

| Coil specs | OD, ID, Width, Weight |

| Factory space | Available area, ceiling height |

| Labor availability | Number of workers per shift |

| Output target | Coils per hour |

| Preferred automation level | Manual, semi-auto, or full-auto |

| Power supply | Voltage and frequency requirements |

Every business is different. That’s why I build machines that can evolve—adding features like automatic film loading, edge protection, or label printing modules over time.

Conclusion

Customizing a steel wire coil packing line isn’t about adding features. It’s about solving real problems. I’ve worked with many small and medium companies that thought automation was out of reach. But with the right planning, even a basic semi-auto setup can revolutionize their process. If you’re unsure where to start, just ask the right questions—and design around your actual needs.