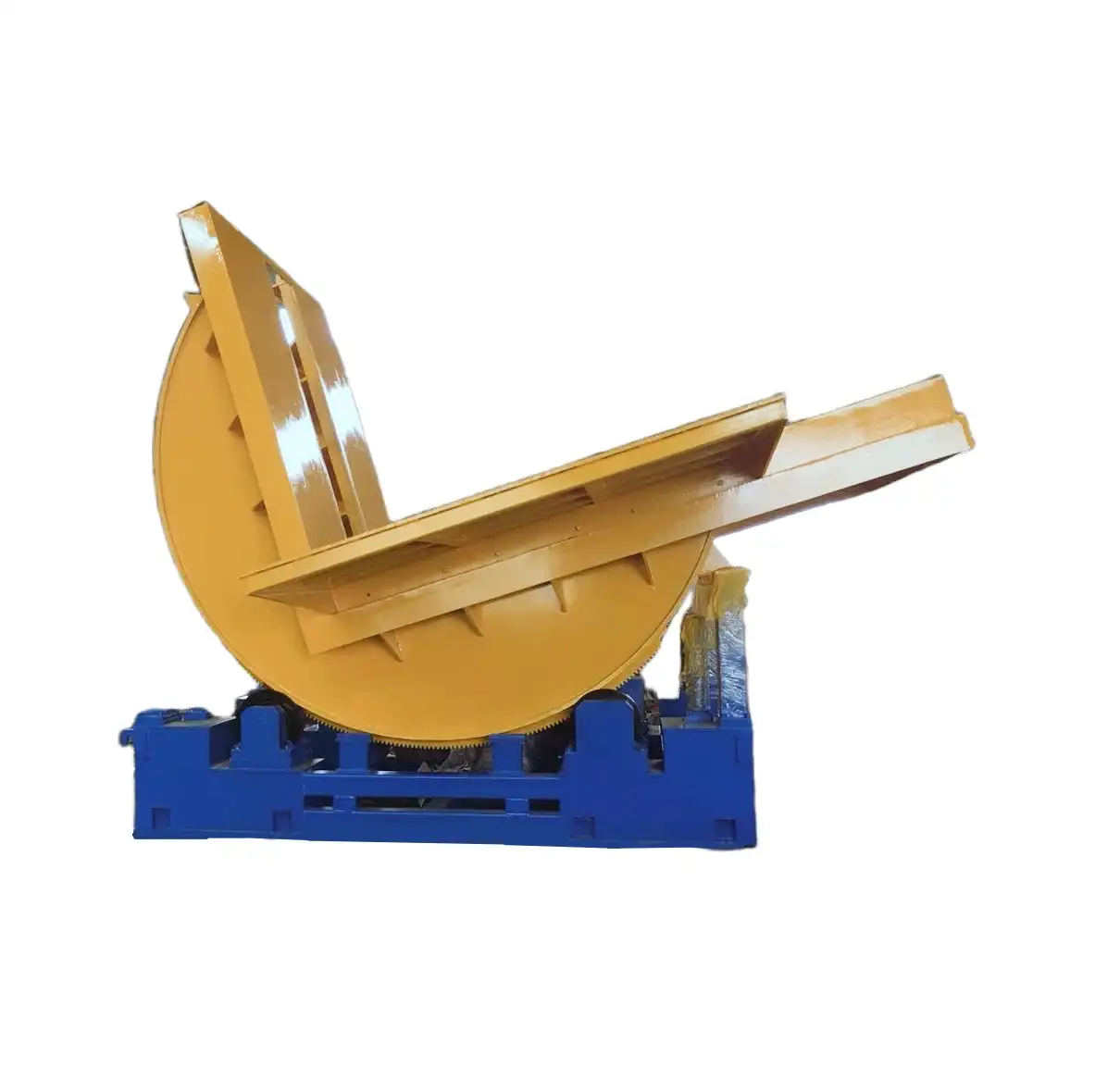

Optimizing coil handling can be a daunting task, but with the right steel coil upender, you can turn challenges into streamlined processes. At FHOPEPACK, our cutting-edge solutions bring you closer to maximizing efficiency in your operations, paving the way for productivity and safety in handling heavy steel coils.

The right steel coil upender is essential for enhancing operational efficiency and safety. It minimizes the manual handling of heavy steel coils, thus reducing workplace accidents. Additionally, it aids in maintaining the quality of coils by preventing physical damage during transfer processes. A strategic choice in upenders directly contributes to effective logistics management.

Choosing the proper upender helps in preserving coil conditions while streamlining operations. It’s vital to align the selection with your specific needs, ensuring that it enables operators to meet production goals without compromising on safety. Let’s delve deeper into why selecting the right steel coil upender is crucial.

1. Why is the right steel coil upender crucial?

Business challenges in manufacturing often revolve around efficiency, safety, and cost-effectiveness. The right steel coil upender addresses these challenges head-on by providing a reliable and safe method for handling heavy coils. Partnering with FHOPEPACK means having access to cutting-edge upending solutions that fit seamlessly into your production line requirements.

Steel coils pose handling risks due to their weight and dimensions. Selecting an adequate coil upender is critical to safely managing these materials. Proper equipment not only enhances safety but also reduces damage risks and labor costs. The right upender, tailored for your coil specifications, also ensures a smooth operation, improving overall productivity.

Understanding the Benefits of the Right Choice

Efficient coil handling enhances productivity and safety. Selecting the correct upender starts with understanding your specific coil specifications, such as size, weight, and material. A meticulous choice ensures reduced damage risks, increased workplace safety, and optimized labor use. This decision not only sobrelies the process but aligns with safety standards, reducing potential hazards.

| Challenges in Coil Handling | Solutions Offered |

|---|---|

| Limited space for operation | Compact upender designs |

| High labor costs | Automated moving systems |

| Coil damage | Precision alignment technology |

From my experience, careful selection of the right upender drastically changes daily operations. Not only does it streamline processes, but it fosters an environment of strategic progression in manufacturing. With the right equipment, it’s not just about moving coils; it’s about moving your entire business forward.

2. What features should you look for in a steel coil upender?作为二级标题;

Innovate your packaging process with the ideal steel coil upender that promises efficiency and safety. Uncover must-have features to streamline operations and ensure top-notch performance in industrial settings. Embrace advancements in machinery for better results today.

The right steel coil upender should include robust construction, efficient load handling, and intuitive controls. These features ensure seamless integration into existing workflows, reducing downtime and increasing safety. Investing in a machine that meets industry standards can improve long-term efficiency and cost-effectiveness.

Prioritizing Key Features

When choosing a steel coil upender, understanding critical features can make all the difference in your operations:

-

Robustness and Durability: The material and design of the upender play a crucial role. Machines made from high-quality steel offer longevity and withstand heavy loads, crucial in industries handling substantial weights.

-

Efficiency of Load Handling: An effective upender balances speed and precision. Quick changeover times improve throughput, while precise mechanisms ensure coils are rotated without causing damage, enhancing product safety.

-

Control Systems: Innovatively designed controls ensure ease of use. Look for upenders with automated systems that offer user-friendly interfaces. These reduce the need for manual adjustments, allowing operators to focus on productivity.

| Feature | Importance | Impact |

|---|---|---|

| Robustness | High | Longevity and load management |

| Load Handling | Essential | Speed and precision |

| Control Systems | Very Important | Ease of use and productivity |

Investing in the right features can optimize your operations, reducing wear and tear and lowering the risk of human error. My own experience has shown that selecting a machine with these key attributes substantially improved our production timelines and safety record.

3. How does the right upender impact operational costs?;

Struggling with operational costs? Choosing the right upender can lead to significant savings. This decision impacts efficiency and safety, streamlining the entire packaging process while minimizing financial strain.

The correct upender reduces manual labor, increases speed, and minimizes product damage. These factors translate into lower operational costs by boosting productivity and ensuring less downtime. By enhancing efficiency and safety, a suitable upender proves to be a worthwhile investment for any operation.

Analyzing Cost Factors

When evaluating the impact of an upender on operational costs, several factors should be considered:

-

Reduction in Manual Labor: Automated upenders cut down on the need for manual handling, reducing the risk of workplace injuries and associated insurance costs. This also means fewer employees are needed for coil handling, leading to labor cost savings.

-

Increased Operational Speed: A well-engineered upender handles tasks quickly and accurately, reducing downtime between operations. This efficiency boost allows for greater output within the same timeframe, increasing overall productivity.

-

Minimized Product Damage: Precise handling prevents damage to coils, significantly reducing waste and the financial impact of reworking or replacing damaged goods. This saving can be substantial, particularly in high-volume operations.

| Cost Factor | Reduction Potential | Financial Impact |

|---|---|---|

| Manual Labor | High | Lower insurance and wages |

| Operational Speed | Increased by 25% | Higher throughput |

| Product Damage | Reduced by 40% | Less waste and rework |

Understanding these elements paints a clearer picture of how a well-chosen upender influences your bottom line. My decision to upgrade our equipment directly led to noticeable improvements in efficiency and cost savings, proving the value of investing in quality machinery.

Conclusion

Choosing the right steel coil upender is vital for operational success, influencing safety, efficiency, and cost control. Making this investment ensures streamlined processes and a more reliable production line, ultimately leading to sustained improvement and profitability in demanding industrial environments.

Choosing the right steel coil upender is vital for operational success, influencing safety, efficiency, and cost control.