How to Improve Pipe Bundling Machine Efficiency in Multi-Product Distribution Centers?

Optimizing pipe bundling machine efficiency is crucial for multi-product distribution centers to maintain smooth operations and meet diverse customer demands. This efficiency directly impacts throughput, reduces labor costs, and minimizes material waste.

Improving efficiency involves several key strategies, including optimizing machine settings for different pipe sizes and materials, implementing robust maintenance schedules, and training operators effectively. Efficient layout design and streamlined material flow are equally important. This multifaceted approach ensures optimal machine performance and overall productivity.

Let’s dive into the specifics of how to enhance pipe bundling machine efficiency in your multi-product distribution center. By carefully considering each aspect, you can unlock significant improvements in your operations.

1. Optimizing Machine Settings for Varied Products

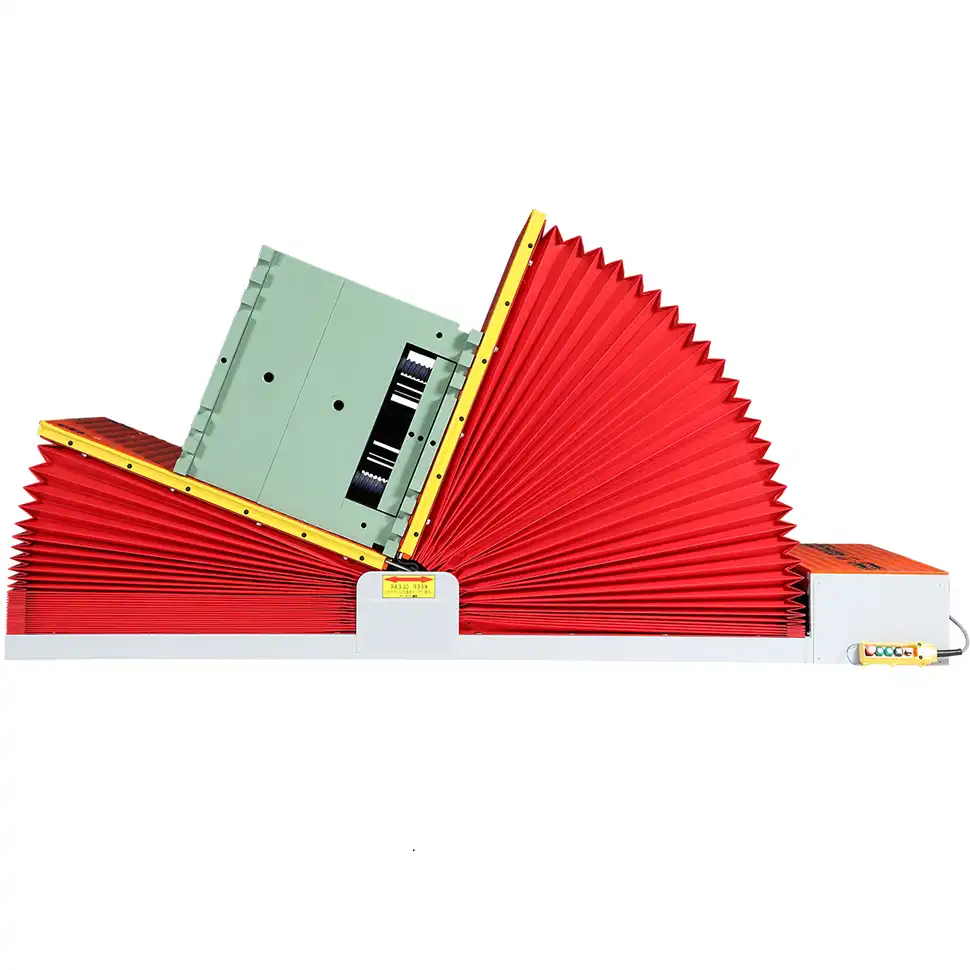

For multi-product distribution centers, flexibility is essential. Pipe bundling machines must be able to handle a wide range of pipe sizes, materials, and bundle configurations, and it is important to maintain machine efficiency during changeover.

Optimizing machine settings for different products is critical to maximizing efficiency. This includes adjusting tension, wrapping speed, and bundle size parameters to suit specific product characteristics. Proper settings minimize material waste and ensure bundle integrity.

Fine-Tuning for Peak Performance: A Deeper Dive

To truly optimize your pipe bundling machine, you need to go beyond basic adjustments. This involves understanding the interplay between various machine settings and how they affect the final product.

1. Understanding Material Properties

Different materials require different handling. Thinner-walled pipes might need gentler tension to avoid damage, while heavier pipes require stronger strapping.

2. Analyzing Data and Implementing Feedback Loops

Keep detailed records of machine performance for each product type. Use this data to refine your settings over time. If you see recurring issues like loose bundles or material breakage, adjust the settings accordingly and use that data for future decision-making.

3. Setting Up Quick Changeover Procedures

Develop standard operating procedures (SOPs) for changing between product types. This will minimize downtime and ensure consistent results.

4. Training and Knowledge Transfer

Train your operators thoroughly on how to adjust machine settings for different products. Encourage them to share their knowledge and best practices with each other. Regular refresher training can help maintain a high level of expertise.

5. Evaluate the benefits of new features and capabilities

Evaluate how a modern pipe bundling machine can adapt to accommodate a wider range of product sizes and shapes, minimizing downtime during product changeovers, and offer additional features like automatic tension control, adjustable wrapping patterns, and quick-release mechanisms.

The Bottom Line

The key to optimizing machine settings is to collect relevant data, carefully plan for various scenarios, and empower your operators with the knowledge and tools they need to succeed. By continuously monitoring and refining your processes, you can achieve significant gains in efficiency and quality.

Below is a comparison of different strapping materials and their ideal tension settings.

| Strapping Material | Ideal Tension (lbs) | Recommended Pipe Type | Notes |

|---|---|---|---|

| Steel | 500-800 | Heavy-duty steel pipes | Provides maximum strength and security |

| Polypropylene (PP) | 200-400 | Lightweight PVC pipes | Cost-effective for lighter loads |

| Polyester (PET) | 300-600 | Medium-weight pipes | Offers good strength and elongation |

| Nylon | 400-700 | Irregular shaped pipes | High elasticity; suitable for uneven bundles |

2. Implementing a Robust Maintenance Schedule

A well-maintained machine is a productive machine. Neglecting maintenance can lead to breakdowns, reduced performance, and costly repairs.

Implementing a robust maintenance schedule is essential for sustained efficiency. This includes regular inspections, lubrication, cleaning, and timely replacement of worn parts. Predictive maintenance techniques can further minimize downtime.

The Pillars of Preventative Care

A comprehensive maintenance program is more than just a checklist, it’s a philosophy of proactive care. Here’s how to set up a system that keeps your pipe bundling machine humming:

1. Establish a Routine Inspection Schedule

Create a daily, weekly, and monthly checklist. Daily checks might involve visual inspections and lubrication, while weekly checks could include tightening bolts and inspecting belts.

2. Follow Manufacturer’s Guidelines

Refer to the machine’s manual for recommended maintenance tasks and intervals. The manufacturer knows best about the specific needs of their equipment.

3. Keep Detailed Records

Track all maintenance activities, including dates, tasks performed, and parts replaced. This data can help you identify trends and predict potential problems.

4. Use Condition Monitoring

Implement technologies like vibration analysis and thermal imaging to detect problems early. These methods can identify issues before they lead to breakdowns.

5. Maintain Spare Parts Inventory

Keep a stock of critical spare parts on hand to minimize downtime when repairs are needed. This is especially important for older machines or those with long lead times for parts.

The frequency of maintenance depends on the machine’s usage and operating environment. However, a general guideline is provided below:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Daily | Check for loose parts, leaks, or unusual noises. |

| Lubrication | Weekly | Lubricate moving parts to reduce friction and wear. |

| Belt Tension Adjustment | Monthly | Ensure belts are properly tensioned to prevent slippage. |

| Sensor Calibration | Quarterly | Calibrate sensors to ensure accurate readings. |

| Parts Replacement | Annually | Replace worn parts such as belts, bearings, and blades. |

3. Training and Empowering Operators

Even the best machine is only as good as the person operating it. Proper training and empowerment can unlock significant gains in efficiency and reduce errors.

Well-trained operators are more efficient and can quickly troubleshoot minor issues. Providing ongoing training and empowering operators to make informed decisions improves overall performance and reduces downtime[(https://www.fhopepack.com/Plastic-Pipe-Packing-Line/)].

Investing in Human Capital

The skills and knowledge of your operators are just as important as the machine itself. Here’s how to maximize their impact:

1. Comprehensive Initial Training

Provide new operators with thorough training that covers all aspects of the machine, including setup, operation, troubleshooting, and maintenance.

2. Ongoing Skill Development

Offer regular refresher courses and advanced training on new techniques and technologies. This keeps operators up-to-date and motivated to improve their skills.

3. Certification Programs

Consider implementing a certification program to recognize operators who have demonstrated a high level of proficiency. This can boost morale and encourage continuous learning.

4. Knowledge Sharing Platforms

Create forums or communities where operators can share their knowledge, ask questions, and learn from each other’s experiences.

5. Empowerment and Autonomy

Empower operators to make informed decisions about machine settings and maintenance. Encourage them to identify and implement improvements to the process. This fosters a sense of ownership and responsibility.

The Bottom Line

Training your operators well and listening to their insights can dramatically improve efficiency. Empowered operators contribute to process improvements and keep your machine running smoothly.

4. Streamlining Material Flow and Layout Design

The layout of your distribution center and the flow of materials can significantly impact the efficiency of your pipe bundling machine. Poor layout and disorganized material flow can lead to bottlenecks, delays, and increased labor costs.

Optimizing material flow and layout design reduces travel time, minimizes handling, and improves overall productivity. Proper staging areas, clear pathways, and ergonomic workstation design contribute to a smoother and more efficient operation.

Material flow is critical to the efficiency of your pipe bundling machine and the entire operation. Careful design and the right equipment can keep things moving smoothly. Streamlined material flow, coupled with a well-designed layout, minimizes bottlenecks and wasted movement. This ultimately translates to higher throughput and reduced operating costs.

Conclusion

Improving pipe bundling machine efficiency in multi-product distribution centers requires a holistic approach. By optimizing machine settings, implementing robust maintenance schedules, training operators effectively, and streamlining material flow, you can achieve significant gains in productivity and reduce costs. Investing in these areas will lead to a more efficient and profitable operation.