Evaluating coil upender solutions can drastically enhance workplace safety by reducing manual handling risks. Discover how to streamline operations and minimize hazards with innovative machinery.

To evaluate coil upender solutions for workplace safety, assess mechanical reliability, operation simplicity, and compliance with safety standards. These elements ensure seamless integration and enhance security in handling processes.

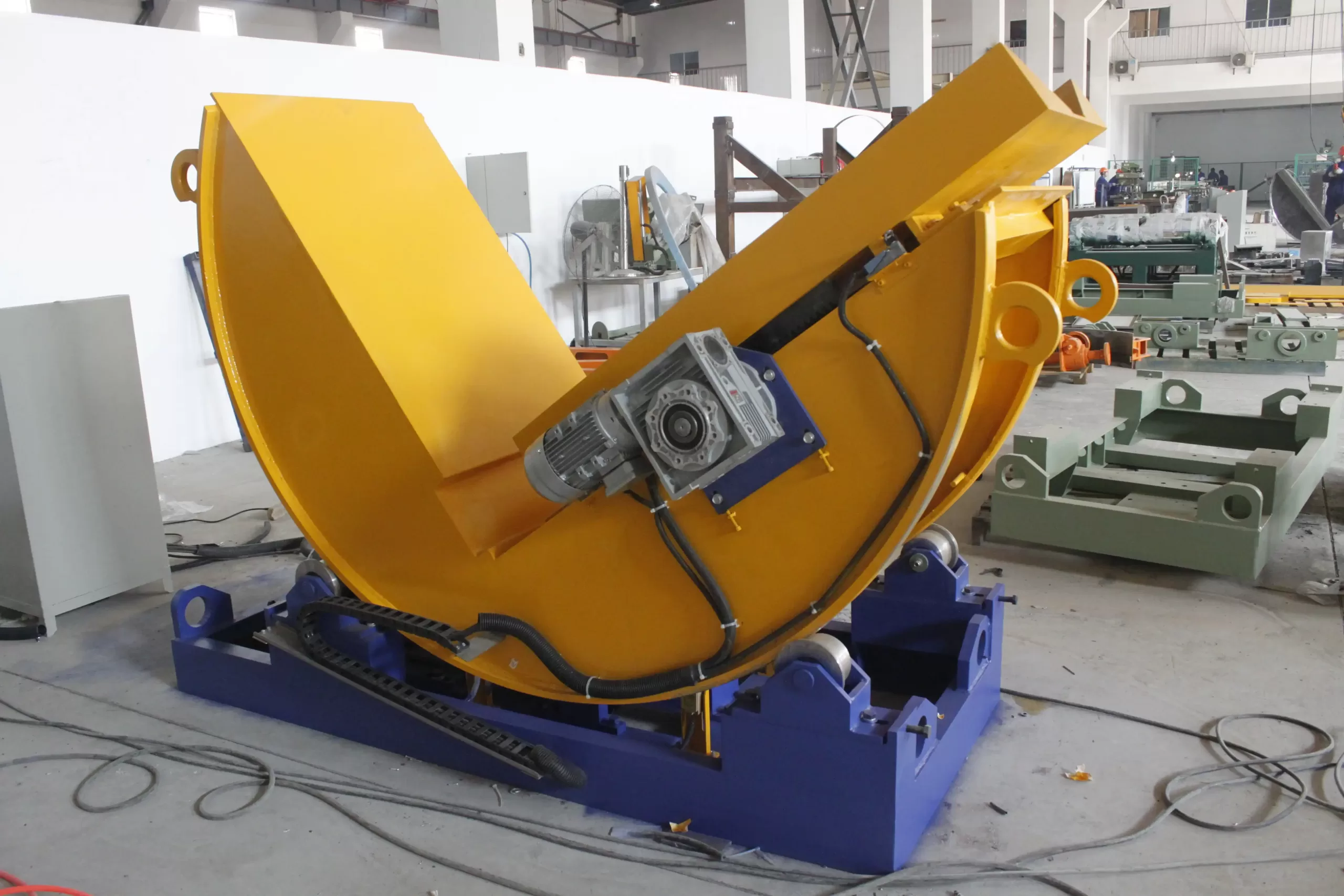

Safety in steel coil handling is crucial. Coil upenders offer a robust solution, shifting heavy coils from horizontal to vertical positions effortlessly. This transition facilitates safe and precise handling, reducing labor strain and material damage. Let’s delve deeper into why coil upenders are integral for your operations.

1. What are Coil Upenders and Why are They Important?

A coil upender is essential in industries that handle heavy coils, like steel manufacturing. It ensures safe, ergonomic transportation, helping avoid workplace injuries and improving operational efficiency.

Coil upenders safely transition steel coils into different orientations, reducing manual labor and injury risks. They enhance workplace productivity and are vital for industries relying on efficient coil handling and storage.

Critical Factors Enhancing Coil Upender Efficiency

Delving into coil upender efficiency involves understanding their impact. Firstly, install them at strategic points. This optimizes workflow, reducing unnecessary movement. Safety features like automatic locking and remote operation enhance safety and user-friendliness. Reliability factors are crucial. Evaluate through:

| Criteria | Impact on Safety & Efficiency |

|---|---|

| Mechanical Features | Robust construction prevents failures, thus improving safety. |

| Operation Simplicity | User-friendly designs reduce mishaps, easing operator handling. |

| Compliance Standards | Adhering to standards ensures overall workplace safety. |

In my past role overseeing logistics at a steel plant, transitioning to coil upenders eliminated many manual processes. This reduced personnel risks significantly, decreased damages, and boosted output by allowing precise inventory management. For your operations, ensure you assess these upender characteristics. Their integration could yield transformative safety and productivity benefits.

Conclusively, coil upenders are not mere equipment. They are pivotal solutions for modern industrial setups. For anyone in coil handling, understanding and integrating these machines could redefine safety standards and operational excellence.

2. How to Assess Safety Features in Coil Upender Solutions?

Safety concerns in coil handling are prominent. Unaddressed risks can lead to severe accidents, costly downtimes, and loss of trust. Explore efficient solutions to safeguard your operations.

To assess safety features in coil upender solutions, focus on robust design, intuitive controls, and emergency functionalities. These ensure secure coil handling, minimizing human error and operational hazards.

Ensure Comprehensive Safety with Coil Upender Solutions

Efficient coil handling is vital for operational safety. Assessing safety features of a coil upender requires focus on several critical aspects to ensure seamless integration into your workflow. Here’s a breakdown to help:

| Safety Feature | Description | Importance |

|---|---|---|

| Robust Design | Solid construction minimizes mechanical failure | Reduces risk of accidents |

| Intuitive Controls | User-friendly interface for easy operation | Prevents operator error |

| Emergency Stop Function | Rapid deactivation in case of malfunction | Quick response to unforeseen issues |

| Safety Sensors | Detect obstacles and prevent accidents | Enhances machine reliability and safe operation |

| Load Capacity Management | Ensures machine handles specified weight | Prevents overloading and structural damage |

For a seamless operation, every safety aspect should be scrutinized. Opt for intuitive controls that reduce operational complexities. Safety sensors are essential to detect potential hazards before they become incidents. A well-designed emergency stop function can save equipment and lives. Load capacity is another important factor. Adhering to manufacturer specifications prevents mechanical strain and prolongs equipment life. When prioritizing these features, remember to comply with industry standards and regulations to ensure maximum safety and efficiency.

3. What Factors to Consider When Selecting a Coil Upender?

Choosing the right coil upender is tricky. Picking the wrong one could mean wasted resources and increased risks. Find solutions that align with your needs.

When selecting a coil upender, consider load capacity, automation level, and safety compliance. These aspects help ensure efficiency and longevity in operations.

Evaluate Crucial Parameters for Coil Upender Selection

Choosing the right coil upender demands understanding specific requirements and evaluating its compatibility with existing systems. Here are several factors to consider:

| Factor | Detail | Relevance |

|---|---|---|

| Load Capacity | Match the upender to coil weight and size | Ensures safe handling and reduces machine wear |

| Automation Capability | Level of automation in operations | Improves operational efficiency and consistency |

| Safety Compliance | Adherence to industry safety standards | Guarantees safe operation and worker protection |

| Energy Efficiency | Power consumption level | Lowers operational costs and environmental impact |

| Maintenance Requirements | Frequency and ease of maintenance activities | Minimizes downtime and extends machine lifespan |

Evaluating these factors helps in smart decision-making. Load capacity ensures that the machine can safely handle the required tasks without risk of failure. Automation capabilities can drastically improve throughput and consistency. Safety compliance is non-negotiable to protect workers and ensure smooth operations. Meanwhile, considering energy efficiency can lead to significant cost savings and support sustainability efforts. Lastly, understanding maintenance requirements helps plan for downtime and repairs, ensuring continuous operation.

Conclusion

Choosing the right coil upender enhances safety and efficiency. Emphasizing thorough evaluation of features and compatibility ensures its optimal integration into the workplace for improved operations and safety.

Choosing the right coil upender enhances safety and efficiency, emphasizing thorough evaluation of features and compatibility for optimal workplace integration.