Are you struggling with bulky, unmanageable steel wire coils taking up precious warehouse space? Imagine transforming those loose wires into neatly compacted bundles, ready for efficient packing and shipping. Steel wire compacting is the answer to streamlining your pre-packaging process, saving space and ensuring secure transit. But how exactly is it done?

Steel wire compacting before packing involves compressing steel wire coils using specialized machinery to reduce volume and create a more stable and manageable form for packaging and transportation. This process typically employs hydraulic or mechanical force to bind the wire tightly, often followed by strapping to maintain the compacted shape.

Compacting steel wire isn’t just about saving space; it’s a crucial step that enhances efficiency and reduces potential damage during handling and shipping. Let’s delve deeper into the methods and benefits of steel wire compacting and discover how to optimize this process for your operations.

Why Steel Wire Compacting is Essential Before Packing

Have you ever dealt with tangled, unwieldy coils of steel wire? The frustration of handling loose wires, the wasted space in storage, and the potential for damage during transit are all too real for industries dealing with steel wire. Steel wire compacting addresses these problems head-on, transforming chaotic coils into organized, space-saving units.

Steel wire compacting is essential before packing to minimize volume, stabilize the wire for handling, prevent unraveling during transport, and optimize packaging efficiency. By reducing the overall size and creating a more uniform shape, compacting simplifies subsequent packaging processes and lowers the risk of damage to the wire and packaging. This leads to cost savings in storage, shipping, and material usage.

Dive Deeper into Compacting Benefits

Steel wire compacting offers a multitude of advantages that extend beyond simple space saving. To fully appreciate its value, let’s break down the key benefits in detail:

Space Optimization and Cost Reduction

The most immediate benefit of compacting is the significant reduction in volume. Loose coils occupy considerable space, increasing storage costs and potentially leading to higher shipping expenses. Compacting drastically reduces the footprint of wire bundles, allowing for denser storage and more efficient loading of trucks or containers. This translates directly into reduced warehousing expenses and lower transportation costs per unit of wire.

Enhanced Handling and Safety

Uncompacted wire coils are notoriously difficult and dangerous to handle. They can roll, tangle, and pose a safety risk to workers. Compacting creates a stable, solid unit that is easier to lift, move, and stack. This improved handling reduces the risk of workplace accidents and streamlines material flow within the production and packaging areas.

Product Protection and Damage Prevention

Loose steel wire is susceptible to damage during handling and transit. Bending, kinking, and unraveling can compromise the quality and usability of the wire. Compacting provides a protective layer, holding the wires firmly in place and minimizing the risk of these types of damage. This ensures that the wire arrives at its destination in optimal condition, reducing scrap and customer complaints.

Streamlined Packaging Process

Compacted wire bundles are much easier to package than loose coils. Their uniform shape and stability simplify the wrapping, strapping, and boxing processes. Automated packaging systems can operate more efficiently with compacted bundles, leading to faster throughput and reduced labor costs. The consistent shape also ensures a neater and more professional final package.

To illustrate the impact of compacting, consider the following comparison:

| Feature | Uncompacted Wire Coil | Compacted Wire Bundle |

|---|---|---|

| Volume | High | Low |

| Storage Space | High | Low |

| Handling Ease | Difficult | Easy |

| Safety Risk | High | Low |

| Damage Susceptibility | High | Low |

| Packaging Efficiency | Low | High |

| Shipping Costs | High | Low |

As the table demonstrates, compacting provides significant improvements across various critical aspects of wire handling and packaging, making it an indispensable step for optimizing efficiency and reducing costs.

Methods of Steel Wire Compacting Before Packing

Wondering how to actually compact steel wire? It’s not just about squeezing the wires together manually. Effective steel wire compacting relies on specialized machinery and techniques designed to achieve consistent and secure compaction. Let’s explore the common methods employed in the industry.

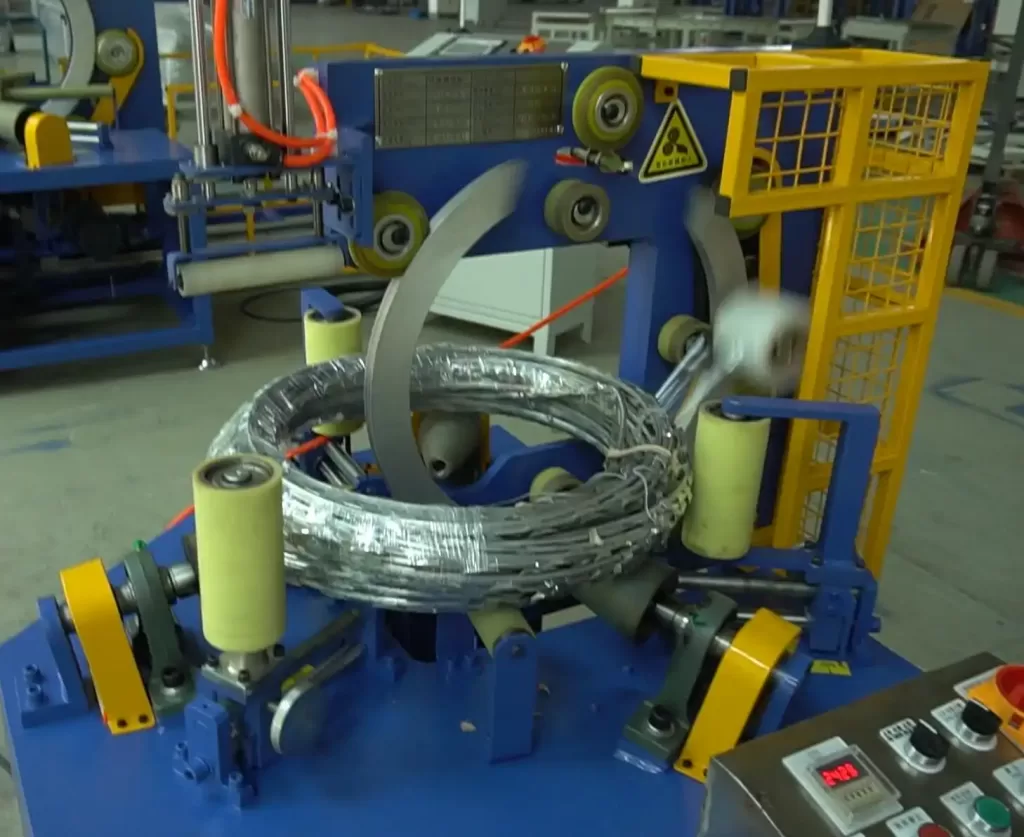

Steel wire compacting before packing is typically achieved through mechanical or hydraulic compression, often using automated [wire compacting machine] that apply force to reduce the coil’s volume and then secure it with strapping or binding. These methods range from basic manual techniques suitable for small-scale operations to fully automated lines designed for high-volume production.

Dive Deeper into Compacting Technologies

The choice of compacting method depends on factors like production volume, wire size and type, and desired level of automation. Here’s a closer look at the common technologies:

Manual Compacting Techniques

For small-scale operations or scrap wire processing, manual methods can be employed. These often involve using levers, winches, or even manual force combined with tools like sledgehammers or crowbars to compress the wire within a container or jig. While labor-intensive and less consistent, manual methods can be a starting point for low-volume needs. Examples from the scrap metal forum illustrate basic manual techniques:

- Weight and Gravity: Using a heavy weight or simply stepping on the wire in a container to compress it.

- Leverage Tools: Employing wooden poles, axle shafts, or sledgehammers to manually force wires into a smaller volume.

These methods are rudimentary and not suitable for industrial-scale production but highlight the basic principle of applying force to reduce wire volume.

Semi-Automated Compacting Machines

Semi-automated machines bridge the gap between manual labor and full automation. These machines typically utilize hydraulic or pneumatic cylinders to provide consistent and powerful compression. Operators manually load the wire coil into the machine, initiate the compacting cycle, and then handle the strapping or binding of the compacted bundle.

- Hydraulic Press Compactors: These machines use hydraulic pressure to compress the wire. They offer greater force and consistency compared to manual methods and are suitable for medium-volume production.

- Pneumatic Compactors: Similar to hydraulic presses but utilize compressed air. They are often faster and cleaner but may offer less force than hydraulic systems for very heavy-duty compaction.

Fully Automated Compacting Lines

For high-volume production environments, fully automated [wire coil packing line] offer the highest efficiency and consistency. These lines integrate wire feeding, compacting, strapping, and often wrapping into a seamless process. Automated systems minimize manual handling, maximize throughput, and ensure uniform compaction quality.

- Inline Compacting Systems: Integrated directly into the wire production or rewinding line, these systems automatically compact wire coils as they are produced.

- Rotary Compacting Machines: These machines often feature a rotating table or carousel that allows for continuous loading and unloading of wire coils while compacting is performed in another station.

Choosing the right method depends on your specific needs and production scale. Automated systems offer the best long-term efficiency for high volumes, while semi-automated or manual methods may be suitable for smaller operations or specific applications.

Optimizing Your Steel Wire Compacting Process

Just having a compactor isn’t enough to guarantee optimal results. To truly maximize the benefits of steel wire compacting, you need to fine-tune your process and consider key factors that influence efficiency and effectiveness. Let’s explore how to optimize your steel wire compacting process for peak performance.

To optimize steel wire compacting before packing, consider factors like wire type, desired compaction level, equipment selection, strapping methods, and integration with your overall packaging line for a streamlined workflow. Attention to these details will ensure consistent compaction, minimize waste, and maximize the return on your investment in compacting technology.

Dive Deeper into Process Optimization

Optimizing your compacting process involves a holistic approach, considering not just the machinery but also the materials and overall workflow. Here are key areas to focus on:

Wire Type and Characteristics

Different types of steel wire may require adjustments to the compacting process. Factors like wire diameter, material hardness, and coating can affect the force and technique needed for optimal compaction.

- Wire Diameter: Thicker wires require more force to compact effectively.

- Material Hardness: High-tensile steel may be more resistant to compaction than softer grades.

- Coatings: Certain coatings might be sensitive to excessive pressure and require gentler compaction settings.

Understanding the specific characteristics of your wire is crucial for setting the right parameters on your compacting equipment.

Desired Compaction Level

The degree of compaction required depends on the application and desired package density. Over-compaction can damage the wire, while under-compaction may not provide sufficient volume reduction or stability.

- Shipping Requirements: Heavier or more fragile items may necessitate tighter compaction for secure transit.

- Storage Density Goals: If maximizing warehouse space is a primary concern, a higher compaction level may be desired.

- Wire Integrity: It’s essential to find a balance that achieves the desired compaction without compromising the structural integrity or properties of the steel wire.

Equipment Selection and Maintenance

Choosing the right compacting equipment is paramount. Consider factors like production volume, wire size range, automation level, and budget. Regular maintenance is also crucial to ensure consistent performance and prevent breakdowns.

- Capacity and Throughput: Select equipment that can handle your production volume and wire sizes efficiently.

- Force and Control: Ensure the machine provides adequate force and precise control over compaction parameters.

- Reliability and Durability: Invest in robust equipment from reputable manufacturers to minimize downtime and maintenance costs.

- Preventative Maintenance: Implement a regular maintenance schedule to keep your compacting equipment in optimal working condition.

Strapping and Binding Methods

Securing the compacted bundle is as important as the compaction itself. Strapping or binding prevents the wire from unraveling and maintains the compacted shape during handling and shipping.

- Steel Strapping: Provides maximum strength and security, suitable for heavy and demanding applications.

- Plastic Strapping: A cost-effective option for lighter bundles, offering good security and flexibility.

- Wire Binding: Using wire to tie the compacted bundle, often employed in manual or semi-automated processes.

- Automatic Strapping Machines: Integrate seamlessly with automated compacting lines for high-speed and consistent strapping.

The choice of strapping method should align with the weight and handling requirements of the compacted wire bundles.

Level 4 Heading: Integrating Compacting into Your Packaging Line

Integrating steel wire compacting into your overall packaging line creates a streamlined and efficient workflow. By positioning the compactor strategically within your production process, you can minimize material handling, reduce bottlenecks, and maximize throughput.

Integrating compacting into your packaging line involves carefully planning the layout and flow of materials to ensure a seamless transition from wire production or rewinding to final packaging. This may include incorporating conveyors, automated transfer systems, and coordinated controls to optimize the entire process.

| Integration Aspect | Benefits | Considerations |

|---|---|---|

| Inline Integration | Continuous flow, minimized handling, high throughput | Requires significant upfront planning, potential for system-wide downtime |

| Buffer Zones | Allows for variations in upstream/downstream speeds, prevents bottlenecks | Requires additional space, potential for inventory buildup |

| Automated Transfer Systems | Reduces manual labor, increases speed and consistency, improves safety | Higher initial investment, requires skilled personnel for programming and maintenance |

| Coordinated Controls | Synchronized operation of compacting and packaging equipment, optimized flow | Complex system integration, requires robust communication protocols |

By carefully considering these integration aspects, you can create a highly efficient and optimized steel wire compacting and packaging line.

Conclusion

Steel wire compacting before packing is not merely an optional step; it’s a strategic imperative for businesses seeking to optimize efficiency, reduce costs, and ensure product integrity. From space savings and enhanced handling to improved product protection and streamlined packaging, the benefits are undeniable. By understanding the methods, optimizing your process, and integrating compacting seamlessly into your workflow, you can unlock significant advantages and elevate your steel wire handling operations to a new level of excellence. Investing in the right [wire coil wrapping machine] and process will pay dividends in the long run, ensuring smoother operations and a stronger bottom line.