How is Blockchain Impacting Mold Upender Supply Chain Transparency?

Feeling lost tracking your high-value mold upenders through the supply chain? The complexity invites risks like delays, damage, and even counterfeit components, eroding trust and inflating costs. Blockchain technology offers a robust solution, creating a transparent, unchangeable record of your equipment’s journey, ensuring authenticity and accountability every step of the way.

Blockchain revolutionizes mold upender supply chain transparency by creating a shared, immutable, and decentralized digital ledger. This technology records every transaction and movement—from raw material sourcing for the upender components to final delivery and installation—in a secure, time-stamped block. Authorized stakeholders gain real-time visibility, fostering trust and making it significantly harder to introduce errors, fraud, or counterfeit parts into the chain.

This shift towards verifiable data and shared truth isn’t just theoretical; it’s actively reshaping how manufacturers, logistics providers, and end-users interact. Dive deeper to understand precisely how this technology enhances traceability, boosts security, and overcomes the traditional hurdles in managing complex industrial equipment supply chains like those for mold upenders.

Understanding Blockchain’s Role in Mold Upender Traceability

Tracking a specialized piece of equipment like a mold upender involves numerous stages and stakeholders, often creating information silos and potential blind spots. Blockchain acts as a unifying digital thread, weaving together disparate data points into a coherent, trustworthy narrative. Its application ensures that the history of each upender is clear, verifiable, and accessible to those who need it.

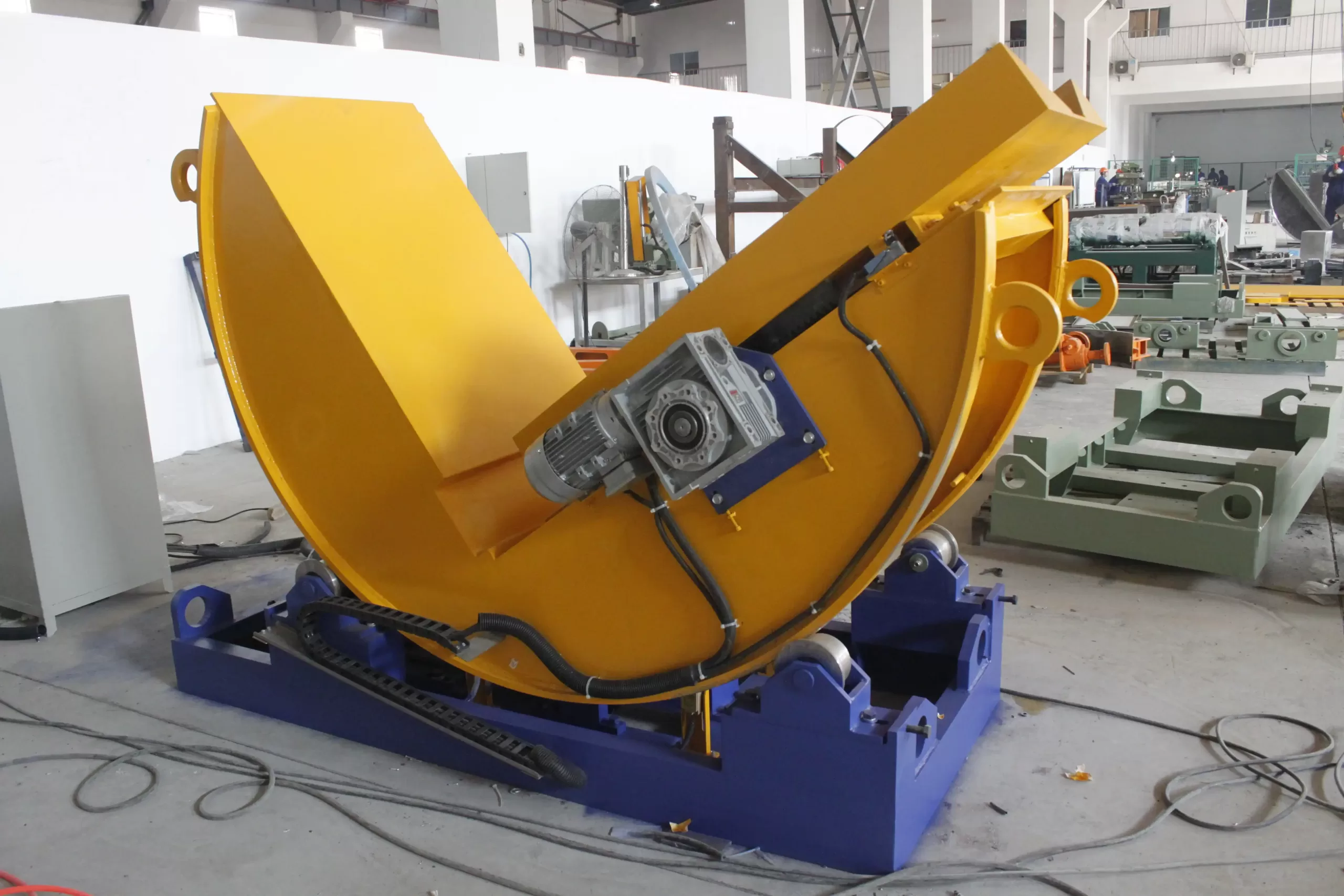

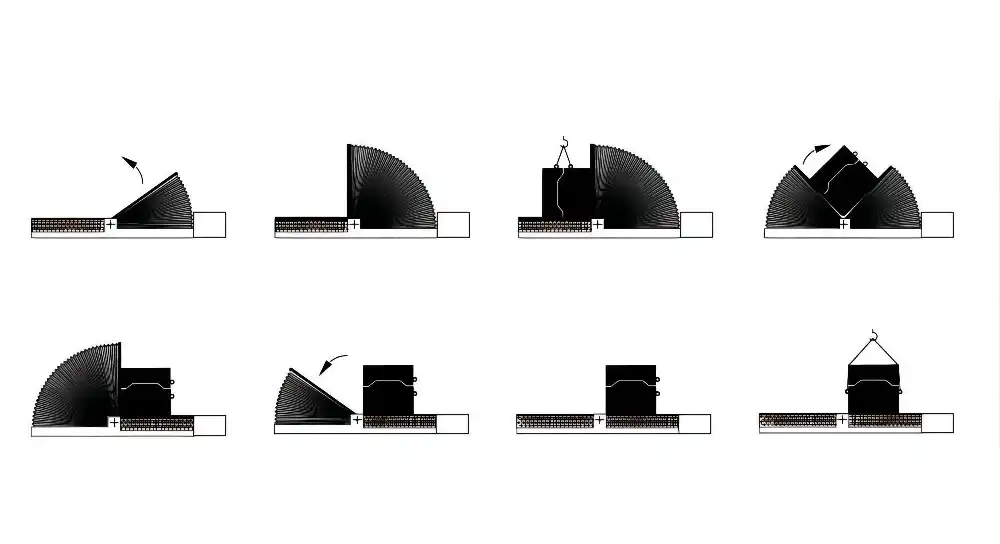

Blockchain enables granular traceability for mold upenders by establishing a decentralized, cryptographic ledger where each significant event in the equipment’s lifecycle is recorded as an immutable block. This includes sourcing specific steel grades, manufacturing key components like hydraulics or motors, assembly milestones, quality control checks (e.g., load testing results), shipping details with potential IoT sensor data integration (temperature, shock), customs clearance, and final installation confirmation. Every entry is time-stamped and cryptographically linked, creating an unalterable chain of custody visible to permissioned participants, dramatically improving provenance verification and accountability compared to traditional paper or centralized database methods.

Breaking Down the Blockchain Advantage for Mold Upenders

To truly grasp the impact, let’s dissect the core technological features of blockchain and how they apply directly to enhancing the transparency of mold upender supply chains.

H3: The Power of the Immutable Ledger

At its heart, blockchain provides an immutable ledger. Once data related to a mold upender – say, the certification of the high-tensile steel used in its frame or the results of a critical weld inspection – is recorded on the blockchain and verified by the network participants, it cannot be altered or deleted. This characteristic is fundamental to building trust. In traditional systems, records can be lost, modified accidentally, or intentionally tampered with. With blockchain, stakeholders can be confident that the information they see accurately reflects the historical events. For instance, if a quality control check is logged, its record remains permanent, providing a reliable audit trail for compliance and warranty purposes. This prevents disputes arising from questionable record-keeping regarding specifications, testing, or component origins.

H3: Decentralization Fosters Trust Without Intermediaries

Traditional supply chains often rely on central authorities or intermediaries to validate transactions and maintain records. This can create bottlenecks and points of failure. Blockchain, being decentralized, distributes the ledger across multiple participants (e.g., the manufacturer, the component supplier, the logistics provider, the end-user). No single entity controls the entire dataset. Trust is established not through a central party, but through cryptographic consensus mechanisms and the shared visibility of the ledger. For a high-value asset like a mold upender, where multiple parties have a vested interest, this decentralized trust model is highly effective. It ensures that all permissioned stakeholders are working from the same verified information, reducing friction and the need for constant reconciliation between different parties’ records.

H3: Capturing Granular Data Points for Comprehensive Visibility

Blockchain allows for the capture and secure storage of a wide array of data points throughout the mold upender’s journey. This goes far beyond simple shipping notifications. It can include:

- Component Provenance: Tracking serial numbers and origins of critical parts like motors, gearboxes, hydraulic systems, and control panels. This helps verify authenticity and combat counterfeit components.

- Manufacturing Milestones: Recording key assembly stages, quality checks, load testing results, and calibration certificates.

- Logistics Data: Integrating with IoT sensors to log real-time data during transit, such as temperature fluctuations, humidity levels, shock events, or GPS location, ensuring the upender wasn’t subjected to damaging conditions.

- Compliance Documentation: Storing digital copies of certifications, safety approvals, and customs documents directly linked to the specific upender unit.

- Maintenance Records: Creating a foundation for a digital passport where post-delivery maintenance, inspections, and part replacements can be logged by authorized service providers.

| Feature | Traditional Tracking | Blockchain-Based Tracking for Mold Upenders |

|---|---|---|

| Data Integrity | Vulnerable to errors & tampering | High (Immutable records) |

| Real-time Visibility | Often delayed, fragmented | Potential for near real-time updates across network |

| Stakeholder Trust | Reliant on intermediaries, often low | High (Decentralized, shared ledger) |

| Auditability | Can be complex, paper-intensive | Streamlined, transparent, verifiable history |

| Counterfeit Risk | Higher due to opaque origins | Significantly Reduced (Verifiable provenance) |

This comprehensive, secure, and transparent data capture transforms mold upender traceability from a reactive, often difficult process into a proactive, value-adding capability.

Key Benefits: Why Use Blockchain for Mold Upender Supply Chains?

Adopting blockchain isn’t just about implementing new technology; it’s about unlocking tangible business benefits specifically relevant to the manufacturing and logistics of heavy, complex equipment like mold upenders. The inherent features of blockchain directly address common pain points in these supply chains.

The core benefits of using blockchain in mold upender supply chains include drastically enhanced transparency across all stages, significant reduction in the risk of fraud (e.g., counterfeit components or falsified compliance documents), improved operational efficiency through faster verification and fewer disputes, and heightened security for sensitive data related to the equipment’s specifications, history, and transit.

Unpacking the Value Proposition

Let’s explore these benefits in more detail, considering the specific context of mold upenders:

- Cost Reduction: While implementation has costs, blockchain can lead to long-term savings. Reduced paperwork, automated verification processes (using smart contracts for milestones like delivery confirmation), faster audits, and fewer disputes directly translate to lower administrative overhead. Locating a specific upender or verifying its history becomes quicker and less labor-intensive. Resolving issues related to shipping damage or component failure is streamlined when an immutable record of conditions and origins exists.

- Improved Compliance and Quality Assurance: Mold upenders often need to meet stringent safety and performance standards. Blockchain provides an irrefutable record that required materials were used, necessary tests were performed (e.g., load capacity verification), and safety certifications are valid and linked to the specific unit. This simplifies compliance reporting for regulators and provides customers with greater confidence in the product’s quality and safety adherence. Tracking material origins also supports ESG (Environmental, Social, Governance) reporting requirements.

- Risk Mitigation: Supply chains face various risks, from shipping delays and damage to component failures and counterfeiting. Blockchain offers enhanced visibility, allowing for earlier detection of potential problems. If a batch of components from a specific supplier is found faulty, blockchain records can quickly identify which mold upender units contain those parts, facilitating targeted recalls or inspections. Integration with IoT sensors provides proof of handling conditions during transit, helping to pinpoint liability in case of damage. The difficulty of introducing counterfeit parts into a blockchain-tracked supply chain significantly mitigates risks associated with substandard components failing under load.

- Enhanced Collaboration and Trust: By providing a single, shared source of truth, blockchain fosters better collaboration between the manufacturer, logistics providers, component suppliers, and the end-user. Disputes arising from conflicting information are minimized. Everyone works from the same data set, improving planning, coordination, and overall relationship quality. This trust extends to the end-user, who gains verifiable proof of the equipment’s authenticity, specifications, and history.

In essence, blockchain transforms the mold upender supply chain from a series of potentially disconnected transactions into an integrated, transparent, and trusted ecosystem, adding significant value beyond simple tracking.

Overcoming Implementation Hurdles: Challenges and Solutions

Facing challenges with complex system integration? Implementing blockchain technology in a mold upender supply chain presents hurdles like cost, technical complexity, and achieving partner buy-in. Strategic planning, choosing the right partners, and focusing on clear use cases are key to navigating these obstacles and unlocking blockchain’s potential.

Key challenges in implementing blockchain for mold upender supply chains include the potentially high initial investment costs, the inherent technical complexity requiring specialized expertise, the need for industry-wide standardization for interoperability, difficulties integrating with existing ERP or manufacturing execution systems (MES), and ensuring data privacy and governance among participating partners.

Navigating the Path to Blockchain Adoption

Successfully implementing blockchain requires acknowledging these challenges and proactively developing strategies to mitigate them.

H3: Addressing Cost Concerns

The initial investment in blockchain technology, including platform development or subscription, hardware upgrades, and personnel training, can be substantial.

- Pilot Projects: Start small with a focused pilot project targeting a specific pain point, such as tracking critical high-value components or verifying final test certifications for mold upenders. This allows for demonstrating ROI and learning lessons before a full-scale rollout.

- Consortium Approach: Collaborate with key suppliers, logistics partners, or even industry peers to share the development costs and build a common platform. This distributes the financial burden and promotes standardization.

- Focus on High-Value Use Cases: Prioritize applications where the benefits (e.g., preventing costly fraud, meeting critical compliance mandates, significantly reducing disputes) clearly outweigh the costs. For mold upenders, tracking provenance of specialized alloys or verifying safety-critical systems might offer the highest initial ROI.

H3: Tackling Technical Complexity & Integration

Blockchain is a sophisticated technology, and integrating it seamlessly with existing operational systems requires expertise.

- Expert Partnerships: Collaborate with technology providers specializing in blockchain solutions for industrial supply chains. Their expertise can accelerate development and ensure best practices are followed.

- Platform Selection: Choose the right type of blockchain. For most supply chains, a permissioned blockchain (where participants are known and authorized) is more suitable than a public one like Bitcoin’s. Evaluate platforms based on scalability, security features, and ease of integration.

- API-Based Integration: Utilize Application Programming Interfaces (APIs) to connect the blockchain platform with existing ERP, MES, warehouse management systems (WMS), and IoT devices. This allows data to flow between systems without requiring a complete overhaul of legacy infrastructure.

H3: Fostering Standardization and Collaboration

For blockchain to be truly effective, participants in the mold upender supply chain need to agree on common standards and actively participate.

- Industry Working Groups: Participate in or initiate industry forums to discuss and agree upon data standards for tracking mold upenders and their components (e.g., data fields, formats, validation rules).

- Clear Data Governance: Establish clear rules about who can access what data, who is responsible for entering data, and how disputes are resolved within the blockchain network.

- Incentivize Participation: Clearly articulate the benefits of participation to partners (e.g., faster payments via smart contracts, reduced administrative burden, enhanced visibility). Sometimes, providing tools or support for smaller suppliers to join the network is necessary.

| Challenge | Potential Solution(s) for Mold Upender Supply Chain |

|---|---|

| High Initial Cost | Pilot projects, consortium model, focus on high-ROI use cases (e.g., safety parts) |

| Technical Complexity | Partner with blockchain experts, select appropriate permissioned platform, user training |

| Lack of Standardization | Industry collaboration, define clear data standards specific to upenders/components |

| Integration Issues | Use APIs for connection to ERP/MES/WMS, phased integration approach |

| Partner Adoption | Clear value proposition, incentives, support for smaller partners, establish governance |

| Data Privacy/Security | Permissioned access controls, data encryption, robust cybersecurity protocols |

Addressing these challenges thoughtfully is crucial for realizing the transformative potential of blockchain in achieving genuine transparency and efficiency in the mold upender supply chain.

Real-World Application: Blockchain and the Mold Upender Lifecycle

Let’s move beyond theory and visualize how blockchain integrates into the practical lifecycle of a mold upender, from its initial design conception through manufacturing, shipping, and operational use. This technology can create a verifiable digital "passport" for each unique piece of equipment.

Blockchain impacts the entire mold upender lifecycle by creating an auditable trail. It starts by logging the certification of raw materials like high-grade steel, tracks the origin and specifications of critical components (motors, hydraulics), records key manufacturing and quality control milestones (assembly steps, load tests), documents shipping conditions via integrated IoT sensors, verifies customs clearance, and finally establishes a digital identity for logging maintenance, ownership transfers, and operational history. This creates unprecedented transparency and a trusted history for each specific mold upender.

From Factory Floor to End-User

Imagine a specific mold upender, Serial #MU-12345. Its blockchain record could begin with the verified receipt of certified steel plates from a specific mill, linked via batch numbers. As manufacturing progresses, the installation and testing of its specific hydraulic power unit (Serial #HPU-9876) are logged, along with its performance test certificate. A critical load test result, confirming its capacity, is digitally signed and added to the chain.

During shipping, IoT sensors integrated with the blockchain platform record temperature, humidity, and G-force data. If the container experiences a significant shock event exceeding predefined thresholds, an alert is recorded on the blockchain, visible to both the manufacturer and the recipient upon arrival. This provides objective data for insurance claims or quality checks before acceptance.

Customs documents are digitally verified and linked to MU-12345’s record, speeding up clearance. Upon arrival at the customer’s facility, installation checklists and commissioning reports are added.

Post-installation, the blockchain serves as a foundation for a verifiable maintenance log. Authorized technicians performing scheduled maintenance or repairs can log their actions, parts replaced (linking new component serial numbers), and inspection results. If the mold upender is ever resold, its entire trusted history—from material origin to the latest service—is transferable to the new owner, potentially increasing its resale value and providing assurance about its condition and provenance. This end-to-end tracking using blockchain provides a level of detail, security, and trustworthiness previously unattainable, solidifying its role in modern manufacturing and supply chain management for complex machinery.

Conclusion

Blockchain technology presents a powerful paradigm shift for mold upender supply chain management. By establishing a secure, transparent, and immutable record of a product’s journey, it directly addresses critical challenges related to traceability, fraud, efficiency, and compliance. While implementation requires careful planning and investment to overcome hurdles like cost and integration, the benefits – enhanced trust, reduced risk, improved quality assurance, and streamlined operations – offer compelling value. Adopting blockchain represents a significant step forward in Supply chain innovation, enabling manufacturers and their partners to build more resilient, accountable, and ultimately more competitive supply chains for high-value industrial equipment like mold upenders.