Hose Coil Winding and Packing Systems: An Industry Analysis# Hose Coil Winding and Packing Systems: An Industry Analysis

I. Introduction to Hose Coiling and Packing

I. A. Defining the Processes: Purpose and Significance

The manufacturing and distribution of industrial and consumer hoses involve critical post-production steps: coiling (or winding) and packing. Understanding the purpose and significance of each process is fundamental to optimizing production efficiency, ensuring product quality, and managing logistics effectively.

Hose Coiling/Winding: This process transforms long, continuous lengths of flexible hose into a compact, typically circular, configuration.[^1] The primary objectives driving this step include:

- Storage Efficiency: Coiled hoses consume considerably less space compared to their straight counterparts. This is crucial for efficient warehouse management, inventory control, and maximizing storage density.[^3]

- Handling and Transport: Coils are inherently easier to handle, move, palletize, and transport than long, potentially unwieldy straight lengths.[^1] This simplifies logistics from the factory floor to the end-user.

- Preparation for Sale/Use: Coiling presents the hose in a standardized format suitable for retail display, industrial dispensing systems, or subsequent packaging steps.[^1] It makes the product ready for the next stage in the supply chain or for direct use by the customer.

- Damage Prevention: Properly executed coiling minimizes the risk of kinking, tangling, abrasion, and other forms of damage that can occur when hoses are handled or stored loosely.[^3]

Hose Packing: Following coiling, packing involves applying materials and methods to secure and protect the coiled hose for storage, transit, and eventual sale.[^1] The importance of effective packing cannot be overstated, as it serves several critical functions:

- Product Protection: Packaging acts as a barrier, shielding the hose (particularly its cover and any end fittings) from physical damage such as abrasions, impacts, crushing, and punctures. It also protects against environmental factors like dust, moisture, UV radiation, and contaminants during handling, storage, and shipping.[^16]

- Maintaining Coil Integrity: Packing methods like strapping, wrapping, or boxing ensure the coil maintains its wound form, preventing it from unwinding, loosening, or becoming tangled during transit.[^15]

- Facilitating Logistics: Securely packed coils form stable, often unitized loads that are easier to stack, store in warehouses, and load onto transport vehicles efficiently and safely.[^20]

- Meeting Customer/Retail Requirements: Packaging must often meet specific end-user needs or retail display standards, including labeling and presentation.[^12]

The effectiveness of the packing process is intrinsically linked to the quality of the initial winding. A poorly wound coil, characterized by uneven tension, loose layers, or inconsistent shape, presents significant challenges for secure packing. Such coils are more susceptible to damage during transit, regardless of the packing materials used. Conversely, the choice of packing method can influence the optimal winding parameters. For instance, a coil destined for shrink wrapping might require different tension or layering compared to one simply being strapped. Achieving a "perfect coil" [^1] – one that is uniform, stable, and tightly wound – is therefore essential not only for the hose’s performance but also for the success of subsequent packing and handling operations.[^1] Preventing issues like kinking [^3] or tangling [^3] during winding is paramount for efficient packing using methods like shrink wrapping or boxing.[^15]

I. B. Overview of Hose Types and Characteristics Influencing Handling

The hose market encompasses a vast array of products designed for diverse applications, including hydraulic systems, pneumatic tools, water transfer, material handling (abrasives, chemicals), and more.[^3] Several key characteristics inherent to these hoses significantly influence the selection and design of appropriate winding and packing systems:

- Material: Hoses are constructed from various materials, including rubber compounds (natural, EPDM, nitrile), plastics (PVC, Polyurethane/PU, Nylon, EVA, PE), composites, and occasionally metal (stripwound, corrugated).[^3] The material dictates crucial properties like flexibility, weight, surface friction (affecting winding tension), temperature resistance, and chemical compatibility with packing materials (e.g., adhesives, films).

- Construction: Most industrial hoses consist of an inner tube to contain the medium, reinforcement layers (textile braids, wire braids, spiral wires) to provide strength against pressure, and an outer cover for protection.[^12] The type and amount of reinforcement heavily influence the hose’s stiffness, pressure rating, minimum bend radius, and overall weight. The cover material determines abrasion resistance and the need for protection from environmental factors.

- Size: Key dimensions include Inner Diameter (ID), Outer Diameter (OD), and Length.[^3] These dimensions directly determine the final coil size, weight, and the capacity requirements of the winding and packing machinery.

- Flexibility & Minimum Bend Radius: This is a critical factor determining how tightly a hose can be coiled without kinking or damage.[^3] Stiffer hoses necessitate larger minimum coil diameters and may require specialized winding equipment with precise tension control to avoid damage.

- Pressure Rating (Working/Burst): High-pressure hoses typically require more substantial reinforcement (e.g., multiple wire braids or spirals), making them heavier, stiffer, and potentially requiring more robust winding and packing solutions.[^3]

- Temperature Rating: The operational temperature range influences material selection.[^12] While primarily an operational concern, extreme temperature ratings might necessitate specific packing materials to protect the hose during storage or transit in harsh climates.

The selection of appropriate winding techniques, machinery, packing methods, and materials is fundamentally driven by these inherent physical and mechanical properties of the hose. Manufacturers must carefully consider factors like size, weight, flexibility, material composition, and surface sensitivity when designing their winding and packing processes.[^12] For example, a heavy, large-diameter, relatively stiff hydraulic hose [^4] demands a heavy-duty coiling machine capable of handling its weight and managing winding tension precisely to avoid damage.[^1] Its packing will likely involve robust methods like heavy-duty strapping or even crating. In contrast, a lightweight, highly flexible garden hose [^9] can be processed on lighter machinery and may only require simple strapping or bagging. Winding machinery specifications frequently list capacity limits based on hose diameter, weight, and material type, underscoring the direct link between hose characteristics and equipment selection.[^1] Ignoring these fundamental properties inevitably leads to inefficient operations, increased risk of product damage, and higher overall costs.

II. Hose Coil Winding Technology

II. A. Objectives of Coiling and Winding

The primary objectives of coiling and winding hoses remain consistent: achieving efficient storage, simplifying handling and transportation, preparing the product for subsequent packaging or sale, and preventing damage such as kinks and tangles that compromise hose integrity and usability.[^1]

A key underlying goal is the creation of a "perfect coil".[^1] This implies a coil with uniform layers, consistent winding tension throughout, and a stable, self-supporting structure (or one properly supported by a spool). Achieving this optimal coil form is critical for efficient downstream processing, including automated packing operations like strapping, wrapping, or boxing, as well as for trouble-free dispensing and use by the end customer.[^54] The specific format of the coil—whether it’s a reel-less coil intended for bulk use or easy dispensing, or a hose wound onto a specific spool or reel for integration into machinery or retail sale—is also a critical consideration determined by the application and market requirements.[^10]

II. B. Winding Methodologies

The method chosen for winding hoses depends heavily on production volume, budget, required consistency, and labor availability. Three main methodologies exist:

- Manual Winding: This involves operators manually coiling the hose, often using simple hand-cranked reels or coiling stands, or even coiling by hand.[^4]

- Advantages: Lowest initial equipment cost, allows for complete operator control over winding speed and tension, adaptable to various hose types and irregular lengths.[^67]

- Disadvantages: Highly labor-intensive and time-consuming, prone to inconsistencies in coil quality and tension, can lead to operator fatigue and potential strain injuries, unsuitable for high-volume production.[^55]

- Semi-Automatic Winding: In this approach, the operator typically loads the hose end, initiates the cycle (often via foot pedal), and unloads the finished coil, while the machine performs the automated winding action.[^2] Some semi-automatic systems may also include automated tying or strapping.

- Advantages: Reduces manual labor and fatigue compared to manual winding, improves consistency, offers faster cycle times than purely manual methods. Represents a balance between cost and automation.[^2]

- Disadvantages: Still requires operator intervention for loading/unloading, limiting overall throughput compared to fully automatic systems. Initial cost is higher than manual setups.

- Fully Automatic Winding: These systems are designed for high-volume production, often integrating directly with the hose production line (e.g., post-extrusion).[^55] They automatically handle hose feeding, length measurement, coiling, cutting, securing (tying, strapping, or preparing for wrapping), and ejection of the finished coil with minimal or no operator involvement.[^2]

- Advantages: Maximizes production speed and throughput, ensures high consistency in coil dimensions and quality, significantly reduces labor costs, enables seamless integration into automated production lines, enhances workplace safety by minimizing manual handling.[^55]

- Disadvantages: Highest initial capital investment, greater complexity requiring skilled maintenance, potentially less flexible for very frequent product changeovers compared to simpler systems.[^67]

The decision between these methodologies extends beyond simple operational preference; it is a strategic choice. It involves balancing capital expenditure against long-term operational savings (labor, material waste), desired production volume, the need for consistent product quality, and the complexity of integrating the system into the overall manufacturing process. While manual methods suffice for niche or low-volume applications, the clear industry trend, driven by the pursuit of efficiency, cost reduction, and quality control, strongly favors increased automation, particularly in medium- to high-volume industrial settings.[^48] Semi-automatic systems offer a viable intermediate step, providing significant improvements over manual methods without the full investment required for complete automation.[^2]

II. C. Key Winding Techniques

Beyond the level of automation, specific techniques are employed to form the hose coil itself:

- Standard Coiling (Reel-less): This involves winding the hose directly upon itself to form a coil without a central spool. The coil is typically secured with straps or ties after winding.[^1] Machinery often uses collapsible mandrels or formers that retract after winding, allowing easy removal of the finished coil.[^59] This method is common for flexible hoses like garden hoses or shorter industrial lengths where the hose itself provides sufficient structure.

- Traverse Winding (Level Winding): This technique is used when winding longer lengths of material onto a spool or core. A traversing guide mechanism moves back and forth across the width of the spool as it rotates, laying the hose down in even, controlled layers.[^11] The linear distance the traverse moves per revolution of the spool is called the "pitch," which must be precisely controlled and synchronized with the spool’s rotation, typically based on the hose diameter, to ensure neat layering.[^63]

- Spooling/Reeling: This involves winding the hose onto a rigid core, spool, or reel.[^4] The spool provides structural support for the hose coil, preventing collapse and maintaining shape. This method is essential for very long lengths, less flexible hoses, or when the hose needs to be dispensed from the spool (as in hose reels used in workshops). Traverse winding is almost always employed when spooling long lengths.

For applications demanding compact, stable winding of long hose lengths onto spools, traverse winding offers significant advantages over simple coiling. By precisely controlling the placement of each wrap and layer, it achieves a much higher "fill factor"—meaning the hose occupies the available space on the spool more efficiently with less air volume.[^63] This controlled layering prevents lower layers from being crushed or distorted by upper layers and ensures the wound package is stable and less prone to shifting or collapsing during handling and transport. Furthermore, the even winding facilitates smoother, tangle-free unwinding or paying out of the hose from the spool.[^63] While the complex geometry of "orthocyclic winding" described for electrical wires [^93] may not be perfectly achievable with bulkier hoses, the principle of controlled, level layering via traverse winding delivers analogous benefits in terms of density, stability, and unwinding performance compared to random or uncontrolled winding methods. The critical need for precise pitch control based on hose diameter further highlights traverse winding’s role in creating high-quality, engineered spooled hose products.[^63]

II. D. Types of Winding and Coiling Machinery

The market offers various types of machinery tailored to different winding techniques and production needs:

- Coilers: These machines are specifically designed to create reel-less coils.[^1] They range from simple manual stands to sophisticated fully automatic systems that integrate length measurement, cutting, and strapping or wrapping functions.[^21] Key features often include adjustable core diameters (using pins or collapsible segments) and variable speed control.[^57] They are often categorized by capacity (light, medium, heavy-duty) and winding orientation (vertical or horizontal).[^1]

- Spoolers/Reelers/Winders: These machines wind hose onto a physical spool or reel, employing drive systems to rotate the spool and often incorporating traverse mechanisms for level winding.[^4] They exist as take-up units (winding material onto a spool) and pay-off units (unwinding material from a spool).[^57] Designs include shafted (spool mounted on a driven shaft) and shaftless (pintle arms grip the spool flanges) configurations.[^57]

- Hose Reels (Storage/Dispensing): While primarily end-use devices for storing and dispensing hoses in workshops, gardens, or emergency vehicles, their design principles are relevant.[^4] They demonstrate different retraction mechanisms – manual crank, spring-driven (automatic retraction), and motor-driven – mirroring the automation levels found in manufacturing winders.[^4] Features like controlled retraction speed (e.g., Coxreels’ EZ-Coil®) address safety concerns also relevant in production environments.[^53]

- Integrated Systems: These represent the highest level of automation, combining coiling or spooling with upstream processes (like extrusion via accumulators) and downstream packing functions (cutting, strapping, wrapping, bagging, boxing, palletizing) into a continuous, automated line.[^56]

II. E. Leading Manufacturers and Equipment Examples

The market for hose winding and coiling machinery includes several key players known for providing standard and customized solutions. Notable manufacturers identified include:

- Reelpower Industrial: Offers a wide range of coiling and reeling equipment, including heavy-duty coilers, spoolers, take-ups, and payoffs, often catering to custom applications.[^1] Competitors include Kenergy, Parfab, Fiberspar, Reelcraft, Coxreels, and others.[^92]

- DRTS: Specializes in equipment for pipe and tube production, offering a comprehensive range of semi-automatic and fully automatic coilers, often integrated with extrusion lines, along with auxiliary equipment like accumulators and shrink wrappers.[^21] Competitors in the broader traffic/data management space (a different DRTS) include Inrix, Miovision, StreetLight [^104], while competitors in power systems (another DRT) include Aegis Power, PCX Aerosystems.[^107]

- Fhopepack: Provides automatic coiling, strapping, and wrapping solutions, often integrated into packing lines.[^22] Competes with companies like Orved, Shandong Dyehome, Shjlpack, Kallfass, Robopac.[^108]

- Shjlpack: Offers automatic hose coilers, strapping machines, and wrapping machines, including horizontal orbital wrappers and integrated packing lines.[^18] Competes closely with Fhopepack and others in the coil wrapping space.[^108]

- RDN Manufacturing: Focuses on post-extrusion equipment, including traversing and lay-flat coilers in single and dual spindle configurations.[^81]

- Marken Manufacturing: Provides standard and custom coiling and re-coiling solutions, often including measuring and cutting capabilities.[^72]

- Coxreels: A major manufacturer of hose, cord, and cable reels for storage and dispensing, known for features like the EZ-Coil® safety system.[^53]

- Hannay Reels: Custom manufacturer of hose reeling and coiling machinery with various rewind options.[^80]

- Other Notable Manufacturers: Cavotec USA [^80], SICA [^72], Periplast [^72], Taymer [^59], O.M.A. (integrated lines) [^95], Wire Machine Systems [^81], Automated Industrial Motion [^81], FENN.[^81]

Equipment examples range from DRTS’s fully automatic coilers (DR-AT-900, DR-AT-1200PE) designed for integration with PE pipe extrusion lines [^56], Reelpower’s heavy-duty coilers (HDC, PC 3000) for robust materials [^1], RDN’s traversing spindle coilers for precise winding [^83], and integrated coiling and strapping systems from Fhopepack and Shjlpack.[^62] Many of these manufacturers emphasize their ability to provide customized solutions tailored to specific production requirements.[^56]

III. Hose Packing Technology

III. A. The Critical Role of Packaging for Coiled Hoses

Once a hose is properly coiled, packaging becomes the next critical step to ensure its integrity throughout the supply chain. Effective packaging serves multiple vital roles:

- Protection: It acts as the primary defense against physical damage (abrasion, impacts, crushing) and environmental hazards (dust, moisture, UV light, contaminants) encountered during handling, storage, and transportation.[^1] This is especially important for hoses with sensitive outer covers or critical end fittings.

- Coil Integrity: Packaging helps maintain the coiled shape, preventing the hose from unwinding, shifting, or becoming tangled, which can lead to kinks or make handling difficult.[^15]

- Handling Efficiency: Well-packaged coils, particularly when unitized on pallets, are easier and safer to handle, stack, and store using standard material handling equipment.[^20]

- Presentation and Information: Packaging provides a surface for branding, labeling (product information, handling instructions, certifications), and often serves as the final presentation for retail or industrial customers.[^12]

Specific risks mitigated by appropriate packaging include abrasion from rubbing against other coils or transport surfaces, crushing under the weight of stacked items, contamination of hose internals or fittings by dust and dirt, moisture ingress that can degrade certain hose materials or promote mold growth, UV degradation of the cover material during outdoor storage, and the general chaos of tangled or unwound coils.[^16]

III. B. Common Packing Methods

Several methods are employed to pack coiled hoses, often used in combination, offering varying levels of protection and cost:

- Strapping/Banding: This involves applying one or more bands around the circumference of the coil to prevent it from unwinding.[^16] Plastic straps (PP or PET) are most common for hoses. While effective for securing the coil shape, strapping alone offers minimal protection against surface abrasion or environmental factors. It can be performed manually, semi-automatically, or fully automatically, often integrated directly after coiling.[^62]

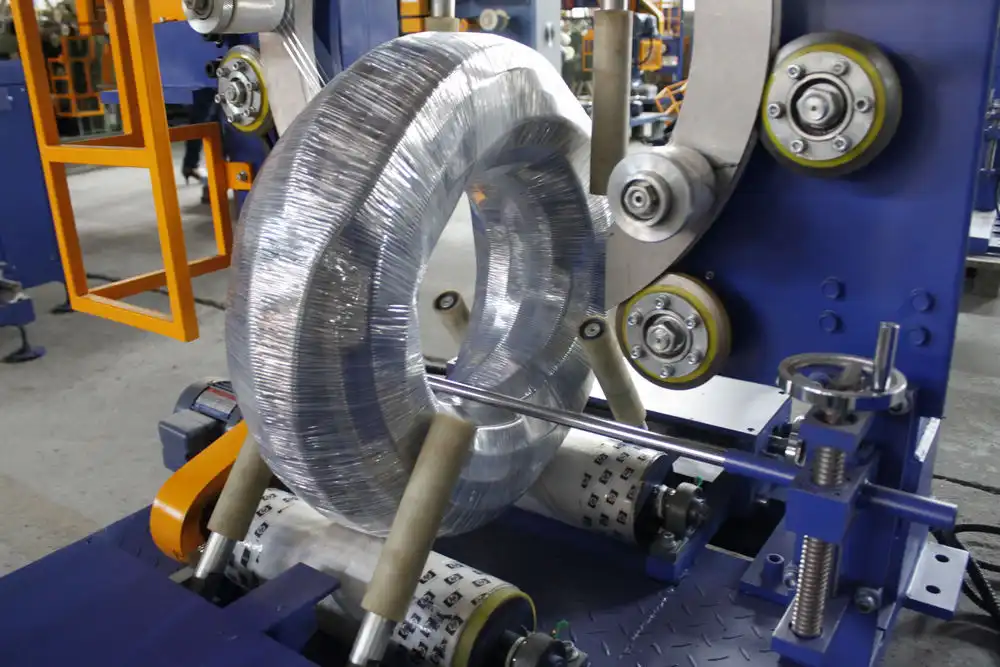

- Stretch Wrapping (Orbital/Horizontal): This method uses stretch film (typically LLDPE) applied by a machine where the coil passes through a rotating ring dispenser, or the coil itself rotates horizontally.[^16] Orbital wrappers are particularly well-suited for ring-shaped items like hose coils, providing excellent surface protection, stability, and containment for individual coils or bundles.[^19]

- Stretch Wrapping (Turntable/Rotary Arm – for Pallets): If multiple coils are palletized, turntable or rotary arm stretch wrappers are used to unitize the entire pallet load with stretch film.[^18] This secures the coils to the pallet and each other for stable transport.

- Shrink Wrapping: The coil is enclosed in a shrink film (available as pre-made bags, tubing, or centerfold film), which is then heated using a heat gun or a shrink tunnel.[^15] The heat causes the film to shrink tightly around the coil, providing a conformal, tamper-evident, and highly protective barrier against moisture, dust, and dirt. This method can be applied to individual coils or used to bundle multiple coils together.

- Bagging: Coiled hoses are placed into bags, usually made of polyethylene (PE).[^15] This offers good protection against dust and moisture and can be a cost-effective solution. Automated bagging machines (autobaggers) can integrate this step into a packing line.[^87]

- Boxing/Cartoning: Placing the coiled hose, which might already be strapped, wrapped, or bagged, into a corrugated cardboard box provides the highest level of physical protection against impacts and crushing.[^1] Boxes facilitate stacking, palletizing, and handling, and are often preferred for retail distribution or shipping individual, high-value coils. Automated boxing lines may involve case erectors and sealers.[^53]

These packing methods represent a clear hierarchy in terms of the level of protection offered and the associated costs. Strapping provides basic coil securement at the lowest cost.[^113] Stretch wrapping and shrink wrapping offer significantly better surface and environmental protection at a moderate cost.[^16] Bagging adds a further layer of defense against contaminants.[^15] Boxing provides the most robust physical protection and facilitates stacking, but typically involves the highest material and processing costs.[^1] Frequently, these methods are combined to achieve the desired level of protection; for example, a coil might be strapped, then bagged, and finally placed in a box with internal dunnage.[^21] The optimal strategy involves balancing the required protection level—determined by factors like hose value, transport hazards, storage conditions, and customer expectations—against the overall packaging cost.

III. C. Essential Packing Materials

A variety of materials are utilized in hose packing operations:

III. C. 1. Straps/Banding

- Plastic: Polypropylene (PP) is economical and widely used for light to medium-duty bundling.[^26] Polyester (PET) is stronger, has less stretch, and often serves as an alternative to steel for heavier loads.[^26] Both are available in various widths, thicknesses, and core sizes, with smooth or embossed finishes (embossed provides better grip for seals).[^26]

- Woven Cord: Offers high strength and flexibility.[^105]

- Steel: Provides maximum strength but is less common for hoses due to potential abrasion and cost, unless dealing with extremely heavy or rigid coils.[^26]

- Paper: An emerging eco-friendly alternative, often reinforced.[^117]

- Seals/Buckles: Metal or plastic components used to join strap ends (for PP, PET, Steel) or wire buckles for woven cord.[^47] Heat sealing (welding) is also common for PP and PET straps, especially in automated machines.[^46]

III. C. 2. Films

- Stretch Film: Primarily Linear Low-Density Polyethylene (LLDPE), used extensively for orbital wrapping of coils and pallet wrapping.[^16] Available in hand and machine grades, various thicknesses (gauges), widths, and colors.[^16]

- Shrink Film: Polyolefin (POF) and Polyvinyl Chloride (PVC) are common types.[^17] POF is generally preferred for its clarity and strength. PVC requires good ventilation due to chloride release during heating.[^29] Supplied as centerfold rolls, tubing, or pre-made bags.[^17]

- VCI Film: Impregnated with Vapor Corrosion Inhibitors to protect metal components (like fittings) from rust.[^47] Available in various film types (blown, cast, stretch).[^106]

III. C. 3. Bags

- Polyethylene (PE) bags are common for basic dust and moisture protection.[^15] VCI bags offer corrosion protection.[^57] Bubble bags provide cushioning.[^57]

III. C. 4. Boxes/Cartons

- Typically made from corrugated fiberboard.[^1] Strength varies based on construction (e.g., single/double wall).

III. C. 5. Dunnage

- Includes materials like foam sheets/planks, bubble wrap, air pillows, packing peanuts, and kraft paper used to fill voids, cushion products within boxes, and prevent movement.[^53] Dunnage air bags are inflatable bags used to brace loads within trucks or containers.[^53]

III. C. 6. End Caps/Protectors

- Plastic caps pushed into or over hose ends to protect fittings and prevent internal contamination.[^137] Edge protectors (angle board), made of cardboard or plastic, are placed on the corners of coils or pallet loads to distribute strap tension and prevent damage to the product from the strap.[^16]

III. C. 7. VCI Products

- Besides films and bags, VCI technology is available in paper, emitters, and capsules that release corrosion-inhibiting vapors within an enclosed package.[^47]

Effective hose packaging rarely relies on a single material. Instead, a synergistic approach is often adopted, layering different materials to address multiple potential risks. A common example might involve strapping a hose coil to maintain its form, enclosing it in a VCI bag to protect metal fittings from corrosion, adding bubble wrap for cushioning, and finally placing it in a corrugated box with dunnage to fill voids and provide robust physical protection during transit.[^21] The specific combination is determined by a careful assessment of the required protection level against the cost and complexity of the chosen materials and processes.

III. D. Types of Packing Machinery

Automating the packing process requires specialized machinery:

- Strapping Machines: These range from simple manual tensioners and sealers/crimpers to semi-automatic machines where the operator positions the strap, and fully automatic machines that feed, tension, seal (heat weld or friction weld for plastic, crimp for metal), and cut the strap, often integrated into conveyor lines.[^46] Automatic strapping can be directly linked with automatic coilers.[^56]

- Orbital Stretch Wrappers: Machines specifically engineered for wrapping elongated or annular products like hose coils, pipes, and profiles.[^19] A rotating ring carries the stretch film dispenser, wrapping the product as it passes through the ring. Available in semi-automatic (operator feeds product) and fully automatic (conveyorized infeed/outfeed, automatic film clamping/cutting) versions.[^80] Options often include dual film reels for faster or reinforced wrapping.[^120]

- Shrink Wrap Systems: These systems comprise two main components: a sealer to create a bag or enclosure of shrink film around the product, and a heat source to shrink the film.[^17] Sealers can be manual impulse sealers, semi-automatic L-bar sealers, or fully automatic continuous motion sealers.[^17] Heat sources range from manual heat guns for low volume to automated shrink tunnels for high throughput.[^17] Systems like the DRTS coil shrink wrapper are specifically adapted for coiled products.[^21]

- Bagging Machines (Autobaggers): Automate the process of placing products into poly bags.[^87] They typically use pre-opened bags on a roll or form bags from tubing. Can be integrated with weighing or counting systems and often include sealing capabilities.

- Boxing/Cartoning Equipment: Automates the creation and sealing of cardboard boxes. Case erectors automatically form flat boxes, case packers (manual or robotic) load the product, and case sealers apply tape or glue to close the box flaps.[^53] These components can be integrated into a complete automated boxing line.

- Integrated Packing Lines: Represent the highest level of automation, combining multiple packaging functions sequentially – for example, coiling → strapping → orbital wrapping → labeling → palletizing – into a single, synchronized system controlled by a central PLC.[^18]

III. E. Leading Manufacturers and Equipment Examples

Several manufacturers specialize in machinery relevant to hose packing:

- Orbital Wrapper Specialists: Handle It [^120], FROMM [^110], Shjlpack [^18], Fhopepack [^22], Robopac [^108], Cyklop.[^110] Handle It offers semi-auto and fully automatic models like the FA-90C specifically for round/coiled products.[^122] FROMM provides FV300 (semi-auto) and FV350 (auto inline) series orbital wrappers suitable for hose rolls.[^121]

- Strapping Machine Providers: Signode [^110], Mosca [^110], StraPack [^110], FROMM Automation [^110], Cyklop [^110], Technopack (JORES TECHNOLOGIES).[^46] Signode offers application-specific machines, though not explicitly for hose coils, their general purpose side-seal or horizontal machines could potentially be adapted.[^118]

- Shrink Wrap System Suppliers: EDL Packaging [^85], Kallfass [^108], US Packaging & Wrapping [^29], DRTS (coil-specific shrink wrapper).[^21] EDL offers a range of wrappers including continuous motion, intermittent, and semi-auto models.[^85]

- Integrated Line Providers: Fhopepack [^22], Shjlpack [^18], DRTS [^21], Massman Automation.[^84] These companies often combine coiling/winding with various packing steps. Fhopepack and Shjlpack, for instance, explicitly offer automatic hose coiling and strapping/wrapping lines.[^62]

Table 1: Comparison of Hose Packing Methods

| Packing Method | Primary Function | Protection Level (Physical) | Protection Level (Environmental) | Relative Cost (Materials & Process) | Automation Potential | Key Machinery Types |

|---|---|---|---|---|---|---|

| Strapping/Banding | Secure coil shape, prevent unwinding | Low | Very Low | Low | High | Manual Tools, Semi-Auto/Auto Strappers |

| Stretch Wrapping | Containment, surface protection, stability | Moderate | Moderate (dust, some moisture) | Low-Moderate | High | Orbital Wrappers, Pallet Wrappers (Turntable/Rotary Arm) |

| Shrink Wrapping | Conformal barrier, tamper evidence | Moderate | High (dust, moisture) | Moderate | High | Sealers (Impulse, L-Bar), Heat Guns, Shrink Tunnels |

| Bagging | Dust & moisture barrier, containment | Low | Moderate-High | Low-Moderate | High | Manual Bagging, Autobaggers |

| Boxing/Cartoning | Physical protection, stacking, handling | High | Moderate (depends on closure) | High | High | Case Erectors, Case Packers, Case Sealers |

IV. Selecting Appropriate Winding and Packing Systems

Choosing the optimal winding and packing machinery and methods requires a systematic evaluation based on specific operational needs, product characteristics, and economic factors.

IV. A. Criteria for Machinery Selection

Several key criteria should guide the selection process for both winding and packing machinery:

- Throughput Requirements: The machine’s processing speed (e.g., coils per minute, packages per hour, linear speed in m/min) must align with the required production output.[^2] Consider peak demands and potential future growth. Cycle time per operation is a critical metric.[^46]

- Hose Specifications Compatibility: The machinery must be capable of handling the specific range of hoses produced, including minimum/maximum ID and OD, weight per unit length, material type (affecting stiffness and surface friction), and required finished coil/spool dimensions (ID, OD, width/traverse).[^1] Minimum bend radius is crucial for coiling without damage.[^36]

- Automation Level: The choice between manual, semi-automatic, and fully automatic systems depends on balancing capital investment with labor costs, desired consistency, production volume, and integration complexity.[^1]

- Integration Capability: For automated lines, assess the machine’s ability to communicate and synchronize with upstream (e.g., extruders, cutters) and downstream (e.g., conveyors, palletizers, labeling systems) equipment.[^18] Compatibility of control systems (PLC, HMI) is essential.[^2]

- Cost (Total Cost of Ownership): Evaluate the initial purchase price (CAPEX) alongside ongoing operational expenses (OPEX), including labor, energy consumption, consumables (film, straps), maintenance, and spare parts, to determine the true long-term cost and return on investment (ROI).[^11]

- Safety: Prioritize machines with robust safety features, such as guards around moving parts, safety interlocks on access doors, emergency stop buttons, and controlled retraction mechanisms (for spring-rewind types) to protect operators.[^4] Ergonomics are important for manual and semi-automatic systems to minimize strain.[^20]

- Footprint and Layout: Ensure the physical dimensions of the machinery fit within the allocated floor space and allow for efficient material flow and operator access.[^1] Consider machine portability if required.[^1]

- Flexibility and Changeover Time: If producing a variety of hose sizes or coil formats, evaluate how quickly and easily the machine can be adjusted or reconfigured. Look for features like tool-less adjustments, programmable recipes (via HMI), and quick-change mandrels or guides.[^2]

- Durability and Maintenance: Assess the robustness of machine construction (e.g., steel frames, quality components), the expected lifespan, ease of access for routine maintenance, availability of spare parts, and the level of technical support offered by the manufacturer.[^29]

IV. B. Matching Packing Methods and Materials to Requirements

Selecting the right packing method and materials involves considering several factors:

- Required Protection Level: The primary driver is the degree of protection needed. Assess risks from physical impacts, abrasion, crushing, dust, moisture, UV exposure, and corrosion (especially for hoses with metal fittings).[^1] Use VCI materials (film, bags, paper) if rust prevention is necessary.[^47]

- Hose Type and Value: High-value hoses, or those with delicate surfaces or critical fittings, generally warrant more comprehensive packing methods like wrapping, bagging, or boxing.[^112]

- Transport Mode and Distance: Rougher handling or longer transit times (e.g., LTL trucking, sea freight) necessitate more robust packaging (e.g., boxing, secure pallet wrapping) compared to dedicated truckload or short local deliveries.[^16]

- Storage Conditions: Consider the storage environment (indoor/outdoor), duration, and potential exposure to temperature extremes, humidity, or sunlight.[^16] Outdoor storage demands UV-resistant and highly water-resistant packaging.

- Cost-Effectiveness: The cost of the packaging materials and the packing process must be weighed against the potential cost of product damage or replacement.[^15] Over-packaging increases costs unnecessarily, while under-packaging risks product loss.

- Customer Requirements: Specific industries or end-users may have mandated packaging standards, labeling requirements, or preferences for ease of unpacking and disposal.[^12]

- Sustainability Goals: Increasingly, companies seek environmentally friendly options. This may involve choosing recyclable materials like paper strapping [^117] or films with recycled content, minimizing material usage through efficient wrapping techniques, or using reusable containers where feasible.[^12]

IV. C. Evaluating Equipment Vendors

Thorough vendor evaluation is crucial before investing in winding or packing machinery:

- Technical Expertise and Support: Does the vendor understand hose manufacturing and packaging challenges? Do they offer application engineering, installation support, operator training, readily available spare parts, and responsive field service?[^57]

- Reliability and Reputation: Investigate the manufacturer’s history, market presence, and reputation for building durable, reliable equipment. Seek customer testimonials or case studies. Analyze their position relative to competitors.[^56]

- Customization Capability: Can the vendor adapt standard machinery or design custom solutions to meet unique requirements regarding hose types, sizes, line integration, or specific packing needs?[^56]

- Quality and Warranty: Examine the build quality, materials used, component sourcing (e.g., use of reputable brands for motors, controls), pre-shipment testing procedures, and the terms of the warranty offered.[^18]

- Cost and Lead Time: Obtain clear quotes covering the full scope of supply (including installation, training, options) and compare pricing. Verify lead times for delivery and installation.[^28]

V. Automation, Integration, and Future Trends

The hose winding and packing sector is increasingly influenced by automation, integration with broader production systems, and emerging technologies aimed at enhancing efficiency, quality, and sustainability.

V. A. The Impact of Automation and Robotics

Automation is transforming hose winding and packing operations, moving beyond simple mechanization to encompass sophisticated control and robotics. The key impacts include:

- Efficiency Gains: Automated systems operate at higher speeds and with greater consistency than manual or semi-automatic methods, leading to significantly increased throughput, reduced cycle times, and optimized utilization of equipment.[^1]

- Labor Reduction: Automation directly reduces the need for manual labor in repetitive tasks like coiling, strapping, wrapping, and handling, helping manufacturers address labor shortages, reduce operational costs, and reallocate personnel to higher-value activities.[^2]

- Consistency and Quality: Automated control over parameters like winding tension, traverse pitch, wrapping overlap, and sealing temperature ensures repeatable, high-quality results.[^20] This reduces product variability, minimizes defects related to improper winding or packing, and enhances final product presentation.

- Safety Improvements: Replacing manual handling with automated processes significantly reduces risks associated with repetitive strain, lifting heavy coils, and interacting with moving machinery.[^4] Automated systems typically incorporate enhanced safety guarding and interlocks.

- Robotics: While specific examples for hose packing are limited in the provided data, the general trend in packaging involves robotics for tasks like pick-and-place of coils, case packing, and palletizing, offering further potential for automation.[^84]

V. B. Integrating Winding and Packing into Production Lines

A major trend facilitated by automation is the integration of winding and packing processes directly into the main hose production line:

- Post-Extrusion Automation: Modern systems often position automatic coilers or spoolers directly downstream from the hose extrusion, cooling, and pulling equipment.[^56] This creates a continuous flow, eliminating intermediate handling steps. Achieving this requires precise synchronization between the extrusion line speed and the winder speed. Accumulators are often used as buffers to allow for coil changeovers or brief stops in the winding/packing section without halting the extrusion process.[^21]

- End-of-Line Systems: Manufacturers increasingly offer comprehensive end-of-line packaging solutions that combine multiple functions – such as coiling, cutting, strapping, wrapping, bagging, boxing, labeling, and palletizing – into a single, integrated automated system.[^18] Companies like Fhopepack, Shjlpack, DRTS, Massman Automation, and EDL Packaging are active in providing such integrated solutions.[^56]

- Control Systems: Integration relies heavily on sophisticated control systems, typically utilizing Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs).[^2] These systems manage the sequencing of operations, control parameters like speed and tension, monitor sensors, communicate between different machines in the line, and provide operators with status information and fault diagnostics.

The push towards integrating winding and packing seamlessly into production lines is fundamentally enabled by automation. Manual or semi-automatic processes inherently create bottlenecks and require buffer zones, disrupting continuous flow. Only fully automatic machines, orchestrated by advanced control systems capable of synchronizing diverse operations like extrusion, cooling, pulling, measuring, coiling, cutting, strapping, wrapping, and material handling, can achieve the efficiency and throughput benefits of a truly integrated line.[^21]

V. C. Smart Technologies and Predictive Maintenance

While detailed evidence for hose-specific machinery is sparse in the reviewed materials, broader industrial trends suggest future advancements will incorporate smart technologies. Drawing parallels from sectors like steel manufacturing [^142], we can anticipate:

- Sensor Integration: Increased use of sensors to monitor critical parameters in real-time, such as winding tension, traverse position accuracy, motor temperature, vibration levels, and material consumption.

- Data Analytics & Predictive Maintenance: Analyzing sensor data to optimize machine performance, identify potential issues before they cause failures, and schedule maintenance proactively, thereby minimizing unplanned downtime.

- IoT Connectivity: Enabling remote monitoring of machine status, performance dashboards, remote diagnostics, and potentially remote adjustments, enhancing operational visibility and support capabilities.[^109]

V. D. Sustainability in Machinery and Packaging Materials

Sustainability is an increasingly important consideration in manufacturing and packaging:

- Material Trends: There is growing demand for more environmentally friendly packaging options. This includes exploring alternatives to traditional plastic strapping, such as paper-based strapping [^117], and using stretch or shrink films with higher recycled content or designed for recyclability.[^12] Optimized wrapping patterns and tension control in automated machinery can also help minimize the total amount of film consumed per coil.[^16]

- Machinery Efficiency: While not a primary focus in the current data for hose machinery, future designs may place greater emphasis on energy efficiency through optimized motor controls (e.g., AC vector drives, servo motors mentioned in some specs [^57]), reduced compressed air consumption, and designs that minimize material waste during processes like film cutting or strapping.[^20]

VI. Conclusion and Strategic Recommendations

VI. A. Summary of Key Findings

This analysis highlights the critical importance of both coiling/winding and packing processes in the hose manufacturing industry. Coiling transforms long hose lengths into manageable formats for efficient storage, handling, and transport, while minimizing damage risks like kinking. Packing provides essential protection against physical and environmental hazards during storage and transit, maintains coil integrity, and facilitates logistics.

A diverse range of machinery exists, spanning manual tools, semi-automatic equipment, and fully automated, integrated lines. The selection of appropriate winding methods (standard coiling, traverse winding, spooling) and packing techniques (strapping, wrapping, bagging, boxing) is fundamentally driven by the specific characteristics of the hose (material, size, flexibility, value) and the operational requirements (volume, cost constraints, protection needs).

Automation and integration represent dominant trends, offering significant benefits in efficiency, labor reduction, consistency, and safety. Fully automated systems, often linked directly to extrusion lines and incorporating multiple packing functions, are becoming increasingly prevalent for medium- to high-volume producers. The choice of automation level, however, remains a strategic decision balancing capital investment, operational costs, and required flexibility.

VI. B. Recommendations for Optimizing Winding and Packing Operations

Based on the analysis, the following strategic recommendations can be made:

- For High-Volume Producers: Prioritize investment in fully automatic, integrated winding and packing lines, ideally connected directly downstream from the extrusion process. This approach maximizes throughput, ensures consistent quality, minimizes labor costs, and streamlines operations. Engage with vendors experienced in complex line integration and capable of providing robust post-installation support and service.[^56]

- For Medium-Volume Producers or Operations with High Product Variety: Evaluate the trade-offs between semi-automatic and flexible fully automatic systems. Semi-automatic machines offer a lower initial investment while still providing significant labor savings and consistency improvements over manual methods.[^2] If full automation is pursued, prioritize machines designed for quick changeovers between different hose sizes or coil formats.[^140] Orbital stretch wrappers offer considerable versatility for packing various coiled products effectively.[^19]

- For Low-Volume or Budget-Constrained Operations: Manual winding tools and basic packing methods can remain viable, provided sufficient labor is available and stringent consistency is not the primary driver. Emphasis should be placed on proper manual coiling techniques (e.g., figure-eight or over-under methods) to minimize kinking and ensure a stable coil for subsequent handling.[^14] Simple strapping or bagging may suffice for basic protection.

- Develop a Strategic Packing Approach: Implement a risk-based assessment to determine the necessary level of packaging protection. Analyze the potential hazards during handling, storage (duration, environment), and transportation (mode, distance, handling) for each product type. Select packing methods and materials (strapping, wrapping, bagging, boxing, VCI, dunnage) that provide the required protection cost-effectively. Consider multi-material solutions for comprehensive protection against various risks.[^1]

- Conduct Thorough Vendor Due Diligence: When selecting machinery suppliers, look beyond the initial purchase price. Evaluate the vendor’s technical expertise, customization capabilities, machine reliability based on references or track record, quality of construction, warranty terms, and the availability and responsiveness of after-sales service and support.[^57]

By carefully considering hose characteristics, production requirements, and available technologies, manufacturers can implement effective and efficient winding and packing strategies that protect product quality, reduce costs, and enhance overall operational performance.

Appendix

Appendix Table 2: Key Manufacturers of Hose Winding & Packing Machinery

(Note: This list is not exhaustive and is based on manufacturers mentioned in the reviewed sources. Specialization may vary.)

| Manufacturer | Primary Focus Areas Mentioned | Key Snippets |

|---|---|---|

| Reelpower Industrial | Coiling Machines, Spoolers, Take-ups/Payoffs (Standard & Custom, Heavy Duty) | [^1] |

| DRTS | Automatic Coilers (integrated w/ extrusion), Semi-Auto Coilers, Accumulators, Shrink Wrappers | [^21] |

| Fhopepack | Automatic Coiling, Strapping, Wrapping Machines, Integrated Packing Lines | [^22] |

| Shjlpack (Shanghai Jinglin) | Automatic Coilers, Strapping Machines, Orbital Wrappers, Integrated Packing Lines | [^18] |

| Handle It, Inc. | Orbital Stretch Wrappers (Semi-Auto, Auto, C-Style for Coils) | [^120] |

| FROMM | Orbital Stretch Wrappers (Semi-Auto, Auto Inline), Strapping Machines, Integrated Systems | [^110] |

| RDN Manufacturing | Coiling Machines (Traversing, Lay Flat, Single/Dual Spindle) for Post-Extrusion | [^81] |

| Signode | Strapping Machines (Application Specific, General), Strapping Heads, Consumables | [^110] |

| Coxreels | Hose Reels (Storage/Dispensing – Manual, Spring, Motor), EZ-Coil® Safety System | [^53] |

| Hannay Reels | Hose Reels (Storage/Dispensing – Manual, Power, Spring Rewind), Custom Reels | [^80] |

| Marken Manufacturing | Coiling & Re-coiling Machines (often with measuring/cutting) | [^72] |

| EDL Packaging | Shrink Wrappers, Shrink Bundlers, Roll Wrappers, Integrated Systems | [^85] |

| Massman Automation | Automated Packaging Equipment (Cartoners, Case Packers, Pouch Fillers), Integrated Lines | [^84] |

| Fhope | Pipe/Hose Bundling, Strapping, Wrapping, Bagging Machines, Packing Lines | [^108] |

| Mosca | Strapping Machines & Systems | [^110] |

| StraPack | Strapping Machines & Systems | [^110] |

| Robopac | Stretch Wrappers (Orbital, Pallet), Shrink Wrappers, Case Packers | [^108] |

| Cyklop | Strapping Machines, Stretch Wrappers (Orbital) | [^110] |

| Taymer | Coilers, Decoilers, Spoolers (often with length measurement) | [^59] |

| O.M.A. Braiding | Hose Braiding Machines, Integrated Hose Production Lines (including taping, spiraling) | [^95] |

| Cavotec USA | Motorized Reels (Cable, Hose, Cord) | [^80] |

| SICA | Automatic Coilers (often for extrusion lines) | [^72] |

| Periplast | Automatic Coilers (often for extrusion lines) | [^72] |

| Kallfass | Shrink Wrapping Machines | [^108] |

| Wrapsolut | Wrapping Machinery | [^108] |

Works cited

[^1]. Coiling Machines: Uses, Types and How To Choose? – Reelpower Industrial, accessed May 6, 2025, https://www.reelpowerind.com/parts-and-service/knowledge-center/efficient-coiling-made-easy.html

[^2]. Automatic Cable and Hose Coil Winding and Bundling Machine …, accessed May 6, 2025, https://ksyuanhan888.en.made-in-china.com/product/fdgTXKZMlehp/China-Automatic-Cable-and-Hose-Coil-Winding-and-Bundling-Machine-Cable-Winding-Binding-Machine.html

[^3]. Air Hoses vs Coiled Air Hoses: The Differences – Metro Sales, accessed May 6, 2025, https://www.metrosales.co.uk/air-hoses/air-hoses-vs-coiled-air-hoses-the-differences/

[^4]. Hose Reels: Characteristics, Features and Uses – IQS Directory, accessed May 6, 2025, https://www.iqsdirectory.com/articles/hose-reel.html

[^5]. Straight & Coiled Hose – Coilhose Pneumatics, accessed May 6, 2025, https://coilhose.com/index.php/straight-and-coiled-hose.html

[^6]. Types of garden hoses and best uses – MYKE, accessed May 6, 2025, https://www.usemyke.com/en-ca/tips/types-of-garden-hoses-and-best-uses/

[^7]. Garden Hose 50 ft Flexible Water Hose Coiled Water Pip Lightweight and No Kink for Coil Hose with 3/4” Brass Connector 10 Pattern Nozzle (Grey+Orange) – Amazon.com, accessed May 6, 2025, https://www.amazon.com/Garden-Flexible-Lightweight-Connector-Pattern/dp/B0CD5KTLQ8

[^8]. Retractable Self Coiling Hoses with 3/4" GHT Solid Brass Fittings – Kink Free and Flexible for Home and Garden Yard (10FT, Blue) – Amazon.com, accessed May 6, 2025, https://www.amazon.com/FUNJEE-Heavy-Duty-Garden-Fittings-Connectors/dp/B0B1ZNLQ9J

[^9]. Garden Hoses: What To Know Before You Buy | The Family Handyman, accessed May 6, 2025, https://www.familyhandyman.com/article/garden-hose-guide/

[^10]. HoseCoil 3/8 inch ID Self Coiling Garden, RV, Marine Outdoor Water Hose (15′ Green), accessed May 6, 2025, https://www.amazon.com/HoseCoil-Coiling-Garden-Outdoor-Water/dp/B07TV8SX1W

[^11]. Oscillate & Traverse Wound Slit Coil – Siegal Steel Company, accessed May 6, 2025, https://www.siegalsteel.com/steel-processes/oscillate-winding

[^12]. The Journey of Our Industrial Hose: From Concept to Creation – NRP …, accessed May 6, 2025, https://www.nrpjones.com/thought-leadership/the-journey-of-our-industrial-hose-from-concept-to-creation/

[^13]. Different Types of Garden Hoses, accessed May 6, 2025, https://www.gardengatemagazine.com/articles/how-to/water-feed/different-types-of-garden-hoses/

[^14]. Wrap Hoses Like a Pro! Never Get Tangles or Knots Again – YouTube, accessed May 6, 2025, https://www.youtube.com/watch?v=gU26qt7p9FE

[^15]. Air Tool Product Packaging – Coilhose Pneumatics, accessed May 6, 2025, https://coilhose.com/packaging

[^16]. Hose Wrapping Machine Hose Coil Wrapper Horizontal Bearing Wrapping Machine Bearing Packing Machine – Coil Wrapping Machine, Coil Packing Machine | Made-in-China.com – Anhui Dixin Machinery Technology Co., Ltd, accessed May 6, 2025, https://dixinmachine.en.made-in-china.com/product/IEDUndOxsKrf/China-Hose-Wrapping-Machine-Hose-Coil-Wrapper-Horizontal-Bearing-Wrapping-Machine-Bearing-Packing-Machine.html

[^17]. How to Shrink Wrap – U.S. Packaging & Wrapping, accessed May 6, 2025, https://uspackagingandwrapping.com/how-to-shrink-wrap.html

[^18]. Coil packing machines & Automatic coiler | Shjlpack, accessed May 6, 2025, https://www.shjlpack.com/products-and-production/

[^19]. Orbital Wrapper – Semi-Automatic Horizontal Spiral Wrapping, accessed May 6, 2025, https://www.getpacked.com.au/p/orbital-wrapper-semi-automatic-horizontal-spiral-w/1-Orbital-Wrapper

[^20]. 5 Benefits of an Automatic Orbital Stretch Wrapper | Omni Group, accessed May 6, 2025, https://omnigroup.com.au/blogs/benefits-automatic-orbital-stretch-wrapper

[^21]. Coil Wrapping Machine (Round Pipe) – DRTS, accessed May 6, 2025, https://drts.com/products/coil-wrapping-machine-round-pipe-2-2/

[^22]. How coil wrapping machine for hose and pipe coil packaging – YouTube, accessed May 6, 2025, https://m.youtube.com/watch?v=l0y_EIyt1uI

[^23]. Understanding Packing in Construction: Its Definition, Uses, and Importance in the USA, accessed May 6, 2025, https://alsyedconstruction.com/understanding-packing-in-construction-its-definition-uses-and-importance-in-the-usa/

[^24]. Introduction to Hydraulic Hose and Fittings – Department of Land and Natural Resources, accessed May 6, 2025, https://dlnr.hawaii.gov/mk/files/2017/01/Freitas-S-18-a.pdf

[^25]. Packaging | Rotor Clip, accessed May 6, 2025, https://www.rotorclip.com/packaging/

[^26]. Guide: Everything you need to know about strapping – IPS Packaging and Automation, accessed May 6, 2025, https://www.ipack.com/solutions/post/strapping-what-you-need-to-know

[^27]. Hose care tips – GOLLMER & HUMMEL, accessed May 6, 2025, https://gollmer-hummel.com/en/application-areas/fire-fighting/hose-treatment

[^28]. Cable Coil Shrink Wrapping Machine – ETW International, accessed May 6, 2025, https://www.etwinternational.com/3-2-cable-coil-shrink-wrapping-machine-487704.html

[^29]. Shrink Wrap Systems – U.S. Packaging & Wrapping, accessed May 6, 2025, https://uspackagingandwrapping.com/shrink-wrap-systems/

[^30]. Metal hose – Wikipedia, accessed May 6, 2025, https://en.wikipedia.org/wiki/Metal_hose

[^31]. Hose Glossary | The Hose Company, accessed May 6, 2025, https://www.thehosecompany.com/hose-glossary/

[^32]. Wholesale Coiled Tubing & Hoses – Freelin-Wade, accessed May 6, 2025, https://www.freelin-wade.com/coiled-tubing-hoses.html

[^33]. Best Garden Hoses for Your Yard – The Home Depot, accessed May 6, 2025, https://www.homedepot.com/c/ab/best-garden-hoses-for-your-yard/9ba683603be9fa5395fab9005153863

[^34]. Pneumatic Coil Hose | Buy Now | G&G Hydraulics Corporation, accessed May 6, 2025, https://www.gghyd.com/hose/coiled.html

[^35]. Coiled Air Hose Assemblies | Dillon Supply, accessed May 6, 2025, https://www.dillonsupply.com/Catalog/Products/Hoses-Tubing-And-Fittings/Hoses/Coiled-Air-Hose-Assemblies

[^36]. Technical Information Industrial Hoses | Semperit, accessed May 6, 2025, https://hoses.semperitgroup.com/info-center/technical-information-industrial-hoses/

[^37]. Hydraulic hose construction and characteristics – Industrial Radiator Service, accessed May 6, 2025, https://industrial-radiator.com/hydraulic-hose-construction-and-characteristics/

[^38]. Tips to Improve Processing Efficiency of Textile Hose Reinforcement – Service Thread, accessed May 6, 2025, https://www.servicethread.com/blog/tips-to-improve-processing-efficiency-of-textile-hose-reinforcement-for-low-and-medium-pressure-applications

[^39]. Coiled Hose | Flexcoil PR14 Flexible Hoses – Freelin-Wade, accessed May 6, 2025, https://www.freelin-wade.com/coiled-tubing-Flexcoil-PR14.html

[^40]. HoseCoil Standard Series, accessed May 6, 2025, https://hosecoil.com/products/hosecoil-standardseries

[^41]. Flexible Hose Winding Machines – Efficient and Reliable – Alibaba.com, accessed May 6, 2025, https://www.alibaba.com/showroom/hose-winding-machine.html

[^42]. 25 ft. Coiled Air Hose | MillerWelds – Miller Welding, accessed May 6, 2025, https://www.millerwelds.com/safety/respiratory/supplied-air-respirators-m30106?ml=270408

[^43]. The Selection and Inspection of Hoses – Purdue Extension, accessed May 6, 2025, https://www.extension.purdue.edu/extmedia/ppp/ppp-89.pdf

[^44]. Safety & Technical Information – Parker Hannifin, accessed May 6, 2025, https://www.parker.com/content/dam/Parker-com/Literature/Hose-Products-Division/Industrial-Hose-Safety-Guide.pdf

[^45]. Coiled Hose – Coilhose Pneumatics, accessed May 6, 2025, https://coilhose.com/index.php/coiled-hose.html

[^46]. Stainless Steel EVA Coil Hose with Nozzle, 50 FT Metal Corrosion Resistant Wa… 810151832722 | eBay, accessed May 6, 2025, https://www.ebay.com/itm/375648832495?chn=ps&mkevt=1&mkcid=28

[^47]. VIAIR 35ft Coil Hose with 1/4" M Swivel and Clip-on Chuck (00037) – JB Tools, accessed May 6, 2025, https://www.jbtools.com/viair-00037-35-ft-coil-hose-with-1-4-m-swivel-with-close-ended-clip-on-chuck/

[^48]. Top 10 Coil hose manufacturers in the World 2025, accessed May 6, 2025, https://www.sourcifychina.com/top-coil-hose-manufacturers-compare/

[^49]. Hose/Hose Operations Flashcards | Quizlet, accessed May 6, 2025, https://quizlet.com/553417070/hosehose-operations-flash-cards/

[^50]. Hose Reels Selection Guide: Types, Features, Applications | GlobalSpec, accessed May 6, 2025, https://www.globalspec.com/learnmore/material_handling_packaging_equipment/material_handling_equipment/hose_reels

[^51]. Seven Easy Steps for Selecting the Proper Hose – Tom Parker Ltd, accessed May 6, 2025, http://www.tom-parker.co.uk/file/literature_file-372.pdf

[^52]. Principles and Applications of Cable Reels – IQS Directory, accessed May 6, 2025, https://www.iqsdirectory.com/articles/hose-reel/cable-reels.html

[^53]. Hose Reels | Compressor World, accessed May 6, 2025, https://www.compressorworld.com/categories/6333/hose-reels

[^54]. The force analysis of the winding roller. | Download Scientific Diagram – ResearchGate, accessed May 6, 2025, https://www.researchgate.net/figure/The-force-analysis-of-the-winding-roller_fig2_301943840

[^55]. (PDF) Design and experiments of an automatic pipe winding machine – ResearchGate, accessed May 6, 2025, https://www.researchgate.net/publication/372843751_Design_and_experiments_of_an_automatic_pipe_winding_machine

[^56]. DRTS Fully Automatic Pipe Coiler Machine – Learn More Here!, accessed May 6, 2025, https://drts.com/products/pe-pipe-automatic-coiler-2/

[^57]. Coiling Machines – Products – Reelpower Industrial, accessed May 6, 2025, https://www.reelpowerind.com/products/coiling-machines.html

[^58]. Wire Spooling & Reeling Machine – Reelpower Industrial, accessed May 6, 2025, https://www.reelpowerind.com/products/take-up-spooling-coiling.html

[^59]. Coilers, Decoilers & Spoolers for Wire and Cable – Taymer, accessed May 6, 2025, https://www.taymer.com/wire-cable/length-measurement/coiler-decoiler-spooler/

[^60]. Wholesale spool reeling machine At Factory Prices Online – Alibaba.com, accessed May 6, 2025, https://www.alibaba.com/showroom/spool-reeling-machine.html

[^61]. Traverse Laying Form Dynamic Spooler Metal Wire Winding Machine – SHIJIAZHUANG SATLE MACHINERY MANUFACTURE CO., LTD., accessed May 6, 2025, https://cnwiremachine.en.made-in-china.com/product/qBWEDdwbMlRo/China-Traverse-Laying-Form-Dynamic-Spooler-Metal-Wire-Winding-Machine.html

[^62]. Automatic coiler and strapping machine – SHJLPACK, accessed May 6, 2025, https://www.shjlpack.com/coiler/Hose-coiling-and-strapping-machine.html

[^63]. Traverse Drive Unit Selection for a Winding System – Amacoil, Inc., accessed May 6, 2025, https://www.amacoil.com/news-articles/traverse-selection-winding-system/

[^64]. Hose Reel Coilers & Winders – New-Line Hose and Fittings, accessed May 6, 2025, https://www.new-line.com/crimpers-reels/hose-reels/hose-reel-coilers-winders

[^65]. Hose, cord and cable reels – Reelcraft Industries, accessed May 6, 2025, https://www.reelcraft.com/wp-content/uploads/reelcraft_catalog.pdf

[^66]. SAFETY REELS – Coxreels, accessed May 6, 2025, https://www.coxreels.com/docs/catalogs/2022/COXREELS_2022_Catalog_-_EZ-Coil-hq.pdf

[^67]. Manual vs. Automatic Hose Reels: Which is Right for You? – TheBlueHose, accessed May 6, 2025, https://thebluehose.com/blogs/news/manual-vs-automatic-hose-reels

[^68]. Types of Hose Reel – CRI Reels, accessed May 6, 2025, http://www.crireels.com/index.php?route=information/information&information_id=21

[^69]. You Probably Haven’t Considered ALL the Pros and Cons of Retractable vs Manual Hose Reels (2024) – YouTube, accessed May 6, 2025, https://www.youtube.com/watch?v=eOhhg2Ppy9w&pp=0gcJCdgAo7VqN5tD

[^70]. Manual HOSE CRIMPING1 | PDF – Scribd, accessed May 6, 2025, https://www.scribd.com/document/468177852/Manual-HOSE-CRIMPING1

[^71]. Semi Automatic Rubber Hose Expanding Machine – SR-HO01 – Alibaba, accessed May 6, 2025, https://www.alibaba.com/product-detail/Semi-automatic-rubber-hose-expanding-machine_1601253604197.html

[^72]. Automatic coiler – All industrial manufacturers – DirectIndustry, accessed May 6, 2025, https://www.directindustry.com/industrial-manufacturer/automatic-coiler-142635.html

[^73]. Automatic hose coiler – SHJLPACK, accessed May 6, 2025, https://www.shjlpack.com/products-and-production/Horizontal-hose-coiler/

[^74]. Reelpower Industrial: Best Coiling, Reeling & Spooling Machines, accessed May 6, 2025, https://www.reelpowerind.com/

[^75]. Traverse Winding Machines – Efficient Cable Production – Alibaba.com, accessed May 6, 2025, https://www.alibaba.com/showroom/traverse-winding-machine.html

[^76]. WO1995003241A1 – Winding machine with programmable traverse control – Google Patents, accessed May 6, 2025, https://patents.google.com/patent/WO1995003241A1/en

[^77]. Automatic hose coiler and strapping machine – SHJLPACK, accessed May 6, 2025, https://www.shjlpack.com/products-and-production/Horizontal-hose-coiler/hose-coiling-strapping.html

[^78]. Automatic hose and pipe coiler and strapping machine line -FHOPEPACK, accessed May 6, 2025, http://icoiler.com/automatic-pipe-coiler/

[^79]. High-Quality Coilers | Reliable Coiling Machines for Your Production – DRTS, accessed May 6, 2025, https://drts.com/products-category/coiler/

[^80]. Hose Reeling & Coiling Machinery Suppliers – Thomasnet, accessed May 6, 2025, https://www.thomasnet.com/products/hose-reeling-coiling-machinery-47124003-1.html

[^81]. 35 Coiling Machine Manufacturers in 2025 – Metoree, accessed May 6, 2025, https://us.metoree.com/categories/101277/

[^82]. Hose coiler – All industrial manufacturers – DirectIndustry, accessed May 6, 2025, https://www.directindustry.com/industrial-manufacturer/hose-coiler-142647.html

[^83]. Coiling Machines – RDN Manufacturing Co., Inc., accessed May 6, 2025, https://www.rdnmfg.com/products/coiling-machines/

[^84]. Massman Automation: Industry Leading Custom Packaging Machinery Solutions, accessed May 6, 2025, https://massmanautomation.com/

[^85]. Industrial Packaging Machines & Solutions, accessed May 6, 2025, https://edlpackaging.com/machines/

[^86]. EDL Packaging: Tailored Packaging Equipment Solutions, accessed May 6, 2025, https://edlpackaging.com/

[^87]. Hose Packing Machine – Made-in-China.com, accessed May 6, 2025, https://usam.made-in-china.com/hot-china-products/Hose_Packing_Machine.html

[^88]. How I Coil a Garden Hose and Avoid Kinking – YouTube, accessed May 6, 2025, https://www.youtube.com/watch?v=vJMEZHmNyf4

[^89]. Traverse Winding Machinery Suppliers – Thomasnet, accessed May 6, 2025, https://www.thomasnet.com/products/traverse-winding-machinery-49030448-1.html

[^90]. Progressive Machine Co S109-RH Single Spindle Traverse Winder W/ Loop Controller, accessed May 6, 2025, https://www.ebay.com/itm/404521916043

[^91]. Reeling Machines – Steel Wire Rope, accessed May 6, 2025, https://steelwirerope.com/tools-and-machinery/reeling-machines/

[^92]. More Hose Reel Manufacturer Listings, accessed May 6, 2025, https://hose-reels.net/more-hose-reel-manufacturer-listings/

[^93]. Coil winding technology – Wikipedia, accessed May 6, 2025, https://en.wikipedia.org/wiki/Coil_winding_technology

[^94]. Reel | ENDO, accessed May 6, 2025, https://www.endo-kogyo.co.jp/english/product/reel/index.html

[^95]. Integrated Hose Lines | Omabraid, accessed May 6, 2025, http://www.omabraid.it/en/products/hose-integrated-lines

[^96]. Fire Truck Hose Deployment: Tips to Optimize Operational Tactics – Pierce Manufacturing, accessed May 6, 2025, https://www.piercemfg.com/pierce/blog/fire-truck-hose-deployment-tips-to-optimize-operational-tactics

[^97]. Top Reel Power International Alternatives, Competitors – CB Insights, accessed May 6, 2025, https://www.cbinsights.com/company/reel-power-international/alternatives-competitors

[^98]. How to Choose a Hose Reel for Compressed Air – Topring, accessed May 6, 2025, https://info.topring.com/en/blog/how-choose-hose-reel-compressed-air

[^99]. Retractable Hose Reel Buying Guide – Blog – The Hosemaster, accessed May 6, 2025, https://www.thehosemaster.co.uk/blog/post/retractable-hose-reel-buying-guide

[^100]. Ultimate Guide to Choosing the Best Retractable Garden Hose Reel – VEVOR Blog, accessed May 6, 2025, https://www.vevor.com/diy-ideas/choosing-the-best-retractable-garden-hose-reel/

[^101]. Factors to Consider When Choosing a Garden Hose Reel – Zephyr Watering, accessed May 6, 2025, https://zephyrwatering.com/blogs/news/factors-to-consider-when-choosing-a-garden-hose-reel

[^102]. www.cbinsights.com, accessed May 6, 2025, https://www.cbinsights.com/company/tulsa-power-holding-corp/alternatives-competitors#:~:text=Reelpower%20Industrial’s%20top%20competitors%20include,Parfab%20Companies%2C%20and%20Fiberspar%20Corporation.

[^103]. Top Reelpower Industrial Alternatives, Competitors – CB Insights, accessed May 6, 2025, https://www.cbinsights.com/company/tulsa-power-holding-corp/alternatives-competitors

[^104]. DRT Solutions – 2025 Company Profile, Funding & Competitors – Tracxn, accessed May 6, 2025, https://tracxn.com/d/companies/drt-solutions/__173FmjgDvp4IJCgu2z5IW3l_3Gj1B87R2r2OtZzGs2k

[^105]. Top 10 DRT Strategies Alternatives & Competitors in 2025 – G2, accessed May 6, 2025, https://www.g2.com/products/drt-strategies/competitors/alternatives

[^106]. DRT Strategies 2025 Company Profile: Valuation, Funding & Investors | PitchBook, accessed May 6, 2025, https://pitchbook.com/profiles/company/130429-27

[^107]. Top DRT Power Systems Alternatives, Competitors – CB Insights, accessed May 6, 2025, https://www.cbinsights.com/company/drt-power-systems/alternatives-competitors

[^108]. Tire Packing Machine Market Trends Analysis 2025-2033: Type and – NEWS CHANNEL NEBRASKA, accessed May 6, 2025, https://www.newschannelnebraska.com/story/52478443/tire-packing-machine-market-trends-analysis-2025-2033-type-and-application-96-page-report

[^109]. The Top Leading Coil Wrapping Machine Manufacturer – SHJLPACK, accessed May 6, 2025, https://www.shjlpack.com/info/the-top-leading-coil-wrapping-machine-manufacturer/

[^110]. Automatic Steel Strapping Machine 2025-2033 Trends and Competitor Dynamics: Unlocking Growth Opportunities, accessed May 6, 2025, https://www.datainsightsmarket.com/reports/automatic-steel-strapping-machine-80693

[^111]. Fully Automatic Tire Packing Machine – Market, Report Size, Worth, Revenue, Growth, Industry Value, Share 2024, accessed May 6, 2025, https://reports.valuates.com/market-reports/QYRE-Auto-1E15159/fully-automatic-tire-packing-machine-global

[^112]. Markets / Coil Wrapping Machine – SHJLPACK, accessed May 6, 2025, https://www.shjlpack.com/Coil-Wrapping-Machine/

[^113]. U.S. SOLID Banding Strapping Kit Pallet Packaging Tool, 3/4" x 1640′ Woven Cord, Polypropylene Composite Banding Coil, 300pcs Metal Buckles, Heavy Duty Tensioner Kit, 2000 lbs Break-Resistant Strength – Amazon.com, accessed May 6, 2025, https://www.amazon.com/U-S-Strapping-Packaging-Polypropylene-Break-Resistant/dp/B0BV6HVZKS

[^114]. Plastic Strapping – U.S. Packaging & Wrapping, accessed May 6, 2025, https://uspackagingandwrapping.com/plastic-strapping/

[^115]. Strapping for Secure Packaging & Bundling | SHIP-PAQ, accessed May 6, 2025, https://www.ship-paq.com/product-category/strapping/

[^116]. Strapping Kit – Walmart, accessed May 6, 2025, https://www.walmart.com/c/kp/strapping-kit

[^117]. Forzaband Eco Paper Strapping – Benchmark Industrial, accessed May 6, 2025, https://www.benchmarkinc.com/forzaband-eco-paper-strapping-p15800.html

[^118]. Application-Specific Strapping Machines – Signode, accessed May 6, 2025, https://www.signode.com/en-us/products/strapping-systems/application-specific-strapping-machines/

[^119]. Packaging-Line-Engineering-and-Automatic-Strapping-Systems – Allstrap, accessed May 6, 2025, https://www.allstrap.com/packaging-line-engineering-and-automatic-strapping-systems

[^120]. Orbital Stretch Wrapping System – Cougar Packaging Solutions, accessed May 6, 2025, https://cougargroup.com/end-of-line-packaging-equipment/orbital-stretch-wrapping-system/

[^121]. Orbital Stretch Wrappers – FROMM Packaging Ltd, accessed May 6, 2025, https://www.fromm-pack.co.uk/wrapping-solutions/orbital-stretch-wrappers/

[^122]. FA-90C Round/Coil Products Orbital Wrap Machine – Handle It, accessed May 6, 2025, https://www.handleitinc.com/products/cs-90-round-products-orbital-wrap-machine/

[^123]. FA-90C Round/Coil Products Orbital Wrap Machine – Handle-It – Source 4 Industries, accessed May 6, 2025, https://www.source4industries.com/products/fa-90c-round-coil-products-orbital-wrap-machine

[^124]. Automatic horizontal hose pipe coil wrapping machine – Copper Coil Packing Line, accessed May 6, 2025, https://www.coilpackingmachine.com/sale-36592040-automatic-horizontal-hose-pipe-coil-wrapping-machine.html

[^125]. Corrugated Hose Pipe Packing Machine Coil Stretch Wrapping Machine Horizontal GW300 380V / 50HZ – Copper Coil Packing Line, accessed May 6, 2025, https://m.coilpackingmachine.com/sale-14035411-corrugated-hose-pipe-packing-machine-coil-stretch-wrapping-machine-horizontal-gw300-380v-50hz.html

[^126]. Orbital stretch wrapper, Orbital wrapping machine – All industrial manufacturers – DirectIndustry, accessed May 6, 2025, https://www.directindustry.com/industrial-manufacturer/orbital-stretch-wrapper-80122.html

[^127]. Signode 2225 2X1847 Polyester Strapping – 3/4" x 2400 ft., .050", 2500 lb … – BGR, accessed May 6, 2025, https://store.packbgr.com/polyester-strapping/3-4x2400ftx050-108945.asp

[^128]. The Complete Guide To Buying Packaging Machinery, accessed May 6, 2025, https://www.industrialpackaging.com/the-complete-guide-to-buying-packaging-machinery

[^129]. Rapid Shrink 25′ Hose Assembly (DS-RS-HOSE), accessed May 6, 2025, https://dr-shrink.com/product/rapid-shrink-25-hose-assembly-ds-rs-hose/

[^130]. Hanging up a boxing bag with paracord, need a 4 point solution – Reddit, accessed May 6, 2025, https://www.reddit.com/r/paracord/comments/el0l48/hanging_up_a_boxing_bag_with_paracord_need_a_4/

[^131]. Track Systems – ProMountings.com, accessed May 6, 2025, https://www.promountings.com/collections/track-systems

[^132]. COILED AIR HOSE EUROX 03-001-011 7M – HomePro, accessed May 6, 2025, https://www.homepro.co.th/p/1003719?lang=en

[^133]. COMPONENTS FOR INDUSTRIAL PACKAGING MACHINES, accessed May 6, 2025, https://essentracomponents.bynder.com/m/7b8bc702a86698d9/original/Essentra_Packaging-machinery-guide-UK-pdf.pdf

[^134]. Air Runway Coiled Hose Festoon Kit | Unified Industries – Columbus McKinnon, accessed May 6, 2025, https://www.cmco.com/en-us/products/crane-systems/enclosed-track-rail-crane-systems/festooning/unified-air-festooning-kit/

[^135]. GARDENA PowerRoll XL Wall Hose Box – Automatically retractable – For 35 m garden hose, accessed May 6, 2025, https://hermie.com/en/201922695/gardena-powerroll-xl-wall-hose-box-automatically-retractable-for-35-m-garden-hose-rotatable

[^136]. Top 10 Strapping machines manufacturers in the World 2025 – Sourcify China, accessed May 6, 2025, https://www.sourcifychina.com/top-strapping-machines-manufacturers-compare/

[^137]. Hose winding machine – Textile machinery, accessed May 6, 2025, https://textile-machinery.bossgoo.com/kw-hose-winding-machine/

[^138]. Signode Packaging Systems Company Overview, Contact Details & Competitors | LeadIQ, accessed May 6, 2025, https://leadiq.com/c/signode-packaging-systems/5a1d82a524000024005d2f1f

[^139]. Signode Company Overview, Contact Details & Competitors – LeadIQ, accessed May 6, 2025, https://leadiq.com/c/signode/5a1d88f3240000240062845a

[^140]. How Do I Choose a Packing Machine? – HonorPack, accessed May 6, 2025, https://honorpack.com/how-do-i-choose-a-packing-machine/

[^141]. The Complete Hydraulic Hose Manufacturing Process Explained, accessed May 6, 2025, https://cntopa.com/the-complete-hydraulic-hose-manufacturing-process-explained.html

[^142]. How AI and Robotics are Reshaping Steel Manufacturing and Distribution, accessed May 6, 2025, https://steelindustry.news/how-ai-and-robotics-are-reshaping-steel-manufacturing-and-distribution/

[^143]. Steel Industry Trends 2025: Innovations, Sustainability & Market Shifts, accessed May 6, 2025, https://www.fedsteel.com/insights/steel-industry-trends-2025/

[^144]. The Future of Steel Pipe Manufacturing: Key Trends and Innovations for 2024, accessed May 6, 2025, https://www.fedsteel.com/insights/the-future-of-pipe-manufacturing-trends-innovations-2024/

[^145]. Innovative Approaches To Steel Packaging And Delivery Efficiency – EOXS, accessed May 6, 2025, https://eoxs.com/new_blog/innovative-approaches-to-steel-packaging-and-delivery-efficiency/