Safety First! Choosing the Right Machinery is Key to Ensuring Workplace Safety.

Workplace safety issues occur frequently, making the selection of the right equipment crucial to maintaining a safe environment.

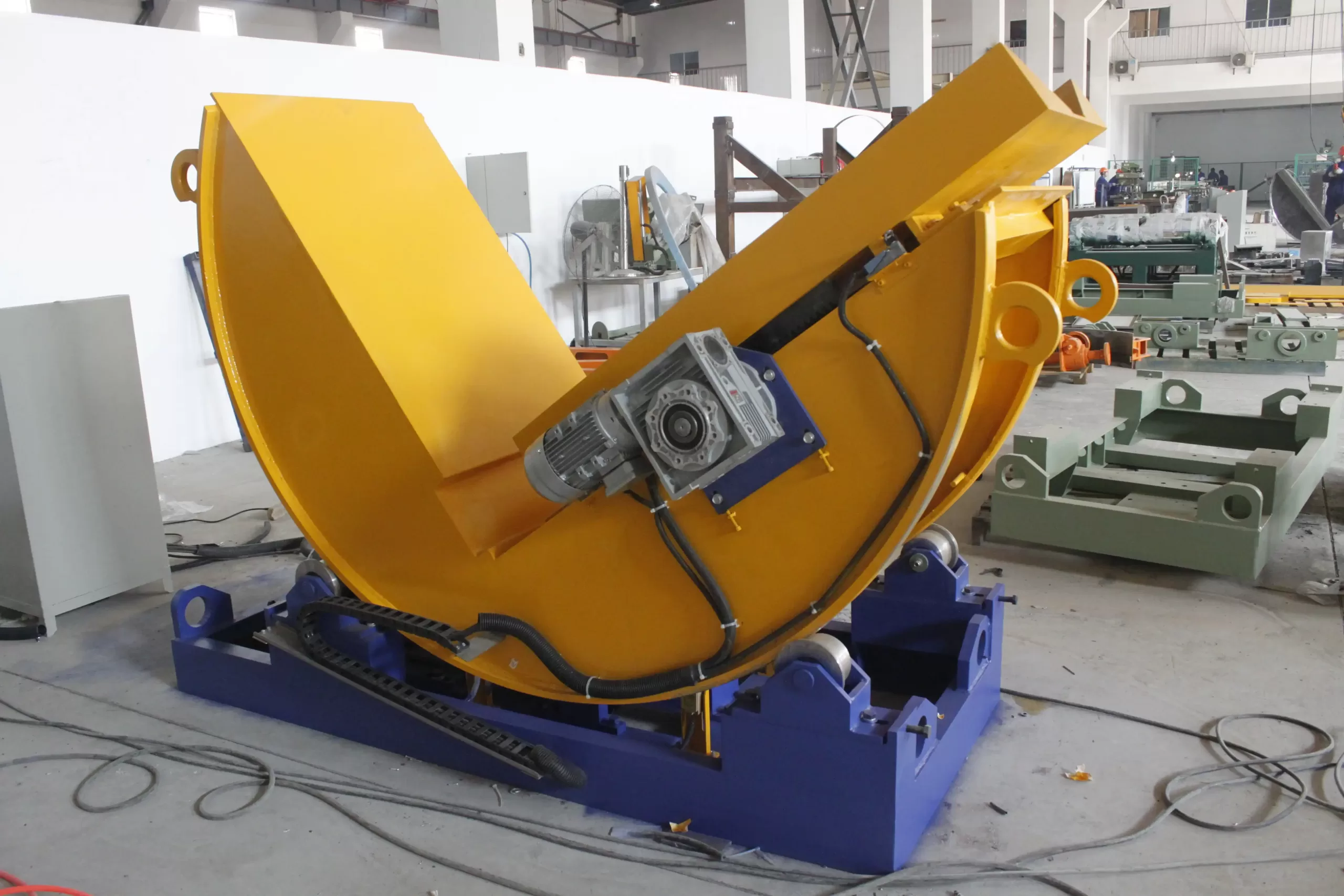

alt with keywords

Safety First! Choosing the Right Machinery is Key to Ensuring Workplace Safety.

Workplace safety issues occur frequently, making the selection of the right equipment crucial to maintaining a safe environment.

Workplace safety is everyone’s responsibility and must be taken seriously. When using a coil upender, associated risks must be carefully evaluated to ensure safe operations.

1. What are the Common Hazards of Coil Upenders?

Using a coil upender can lead to several safety risks. The PAS strategy can help raise awareness and reduce accident rates.

Improper use or inadequate maintenance of machinery can lead to workplace injuries. Common risks with coil upenders include incorrect operation, electrical failures, and falling objects. These risks not only jeopardize employee safety but can also damage equipment and disrupt production.

Known Hazards in Coil Upender Operations

In my career, I have witnessed severe accidents due to a lack of risk management. To analyze this in more depth, we can break down the potential hazards into the following areas:

- Operational Errors: New employees often lack experience, making them prone to mistakes when handling complex machinery. To mitigate this risk, companies should enhance training and supervision.

- Insufficient Maintenance: Even the most advanced equipment needs regular inspections and maintenance to function properly. Irregular maintenance can lead to aging equipment or failure.

- Environmental Factors: The safety of the work environment also significantly impacts operational safety. For example, slippery floors can lead to staff injuries.

The table below shows common safety hazards and their potential impacts on work:

| Hazard Type | Potential Impact | Preventive Measures |

|---|---|---|

| Operational Error | Injury, Equipment Damage | Training, Supervision |

| Insufficient Maintenance | Equipment Failure, Production Interruptions | Regular Inspections, Maintenance |

| Environmental Factors | Injuries, Reduced Productivity | Improve Workplace Environment, Ensure Safe Operating Conditions |

We cannot afford to overlook workplace safety. Selecting the optimal equipment solution can effectively reduce or even eliminate these dangers, ensuring the safety of every employee.

2. How Can Technological Innovations Reduce These Risks?

Packaging heavy steel coils can be risky. Recognizing these risks is key to ensuring safe and efficient operations.

Technological innovations like automated packaging systems reduce risks by improving consistency, lowering manual labor needs, and minimizing handling errors. These solutions enhance safety, reduce human error, and increase operational efficiency.

Exploring Technological Solutions for Risk Reduction

Innovative packaging machinery can greatly reduce the risks and inefficiencies associated with coil handling. Automation plays a crucial role in this transformation by providing precise execution and reducing the need for direct human intervention. The table below highlights some specific technologies and their impacts:

| Innovation | Description | Impact on Risk Reduction |

|---|---|---|

| Coil Wrapping Machine | Automates secure wrapping of coils | Ensures consistency, reduces manual errors |

| Pallet Inverter | Flips pallets safely | Minimizes risks during transportation |

| Coil Upender | Safely rotates coils | Prevents manual handling injuries |

| Conveyor Systems | Automates transport processes | Reduces collision and handling time |

By implementing these technologies, companies can streamline operations and focus on maximizing safety. It’s important to assess the specific needs of your facility to select the most appropriate solutions. In my experience, working closely with engineers and operators to customize systems can lead to safer and more efficient outcomes.

3. What are the Best Practices for Implementing Safety Measures?

Managing safety in industrial settings requires proactive planning. Identifying potential hazards and implementing robust safety measures can mitigate risks.

Safety measures like regular maintenance, training, and using safety equipment are crucial. These practices reduce accident rates, improve worker safety, and enhance overall operational efficiency.

Effective Strategies for Safety Implementation

Ensuring safe industrial operations requires a comprehensive approach that integrates safety into everyday practices. Below are key strategies along with their benefits:

| Strategy | Description | Benefit to Workplace Safety |

|---|---|---|

| Regular Maintenance | Routine inspections and repairs | Prevents equipment failures and accidents |

| Worker Training | Continuous education and skill updates | Enhances competency and hazard awareness |

| Safety Equipment Use | Proper utilization of protective gear | Reduces injury from unexpected incidents |

| Emergency Protocols | Clear and rehearsed action plans | Ensures efficient response in emergencies |

Integrating these practices into daily operations helps create a culture of safety. Experience has taught me that consistency in applying these measures improves overall safety standards. Establishing a strong safety protocol not only protects workers but also increases productivity by minimizing downtime and enhancing morale.

Conclusion

Assessing risks in coil handling and implementing robust technological solutions and safety measures are essential to protecting workers and minimizing hazards. By embracing these practices, businesses can achieve safer, more efficient packaging processes.

Summarize the importance of assessing coil upender risks and implementing technological solutions and safety best practices to minimize hazards and protect workers.