Optimizing Mold Handling: A Deep Dive into 180-Degree Mold Tilter Technology and Selection Criteria

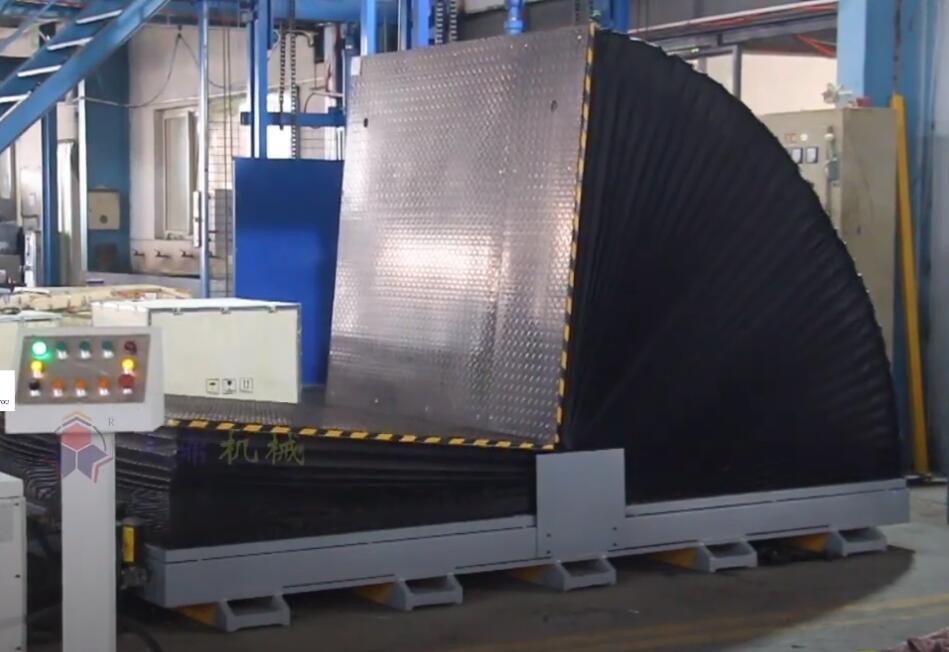

The 180-degree mold tilter, also known as a mold flipper or mold turnover machine, represents a critical piece of equipment in modern manufacturing, particularly within industries reliant on injection molding, die casting, and tool and die making. These machines are engineered to safely and efficiently manipulate heavy, cumbersome molds, significantly enhancing workplace ergonomics and drastically reducing the downtime associated with manual or less sophisticated turning methods. As noted in various industry publications like Manufacturing Engineering and Modern Machine Shop, optimizing mold handling directly correlates with improved production throughput and worker safety. With a diverse range of models available, selecting the appropriate mold tilter necessitates a thorough evaluation of key technical and operational parameters to ensure alignment with specific production demands and safety protocols.

This analysis provides an in-depth comparison of the crucial features and technical specifications to consider when evaluating 180-degree mold tilters, drawing upon insights from engineering principles, industry best practices, and patent literature concerning material handling innovations.

1. Load Capacity: Matching Power to Payload

The cornerstone of mold tilter selection is its load capacity. Industrial molds vary significantly in weight, from relatively modest units under 5 tons to massive dies exceeding 50 tons or more, commonly found in automotive or large appliance manufacturing.

- Specification: Define the maximum and typical weight range of molds used in your facility.

- Safety Margin: Select a tilter with a capacity that comfortably exceeds your heaviest mold, incorporating a safety factor as recommended by industry standards (e.g., ASME B30.20 for Below-the-Hook Lifting Devices). Overloading poses severe risks to personnel and equipment.

- Industry Examples: Standard models often range from 5 to 20 tons, while heavy-duty hydraulic systems cater to the 30-50+ ton range.

2. Maximum Mold Dimensions & Geometry Handling

Beyond weight, the physical size and geometry of the mold dictate the required machine specifications. Complex mold shapes or exceptionally large dimensions necessitate tilters with adequate table size, clamping range, and clearance.

- Working Envelope: Verify the maximum length, width, and height the tilter can accommodate.

- Adaptability: Advanced models feature adjustable clamping systems or customizable support structures to securely handle diverse mold footprints, a feature often highlighted in patents related to versatile workholding solutions (e.g., Patent US9186787B2 discussing adjustable clamping).

flipper lift table& mold reverser 3. Drive Mechanism: Hydraulic vs. Electro-Mechanical

The core turning mechanism is typically powered either hydraulically or electro-mechanically, each offering distinct advantages:

- Hydraulic Systems:

- Pros: Superior power density for handling extremely heavy loads, inherently smooth and controlled motion due to fluid dynamics, robust performance.

- Cons: Potential for leaks, requires hydraulic power unit, generally slower cycle times compared to mechanical drives. Research often points to the reliability of hydraulic systems in high-load, high-force applications.

- Electro-Mechanical Systems:

- Pros: Generally faster cycle times, higher energy efficiency, easier maintenance (no hydraulic fluid), precise control via Variable Frequency Drives (VFDs), cleaner operation.

- Cons: May have limitations on peak load capacity compared to hydraulics, potentially higher initial cost for high-torque motor/gearbox combinations. Studies in industrial automation often favor electro-mechanical drives for speed and precision in moderate load ranges.

4. Operational Speed and Cycle Time Efficiency

Rotation speed and overall cycle time directly impact production flow, especially in high-volume environments.

- Variable Speed Control: Modern tilters often incorporate VFDs (for electro-mechanical) or proportional valves (for hydraulic) allowing adjustable rotation speeds. This enables optimization for different mold types and operational needs – slower speeds for delicate molds, faster for robust ones.

- Throughput Calculation: Evaluate cycle times (loading, clamping, tilting, unclamping, unloading) in the context of your Takt time or production targets. Reducing mold changeover time is a key tenet of Lean Manufacturing principles.

5. Clamping and Securing Systems: Ensuring Stability

The clamping system is paramount for securing the mold during the 180-degree rotation, preventing slippage or catastrophic failure.

- Mechanism Types: Common systems include hydraulic clamps, motorized chain V-blocks, screw clamps, or magnetic systems (less common for tilting).

- Safety Features: Look for redundant clamping mechanisms, pressure monitoring (hydraulic), load sensors, and fail-safe locking features. Recent patent activity often centers on enhancing clamping security and automation (e.g., self-centering clamps).

- Surface Protection: Ensure clamping surfaces are designed to prevent damage to valuable molds (e.g., non-marring contact pads).

6. Control Systems, Automation, and Ease of Use

User-friendly controls streamline operation and minimize errors.

- Interface: Options range from simple pendant controls to sophisticated touchscreen Human-Machine Interfaces (HMIs). HMIs can offer diagnostics, maintenance schedules, and integration capabilities.

- Automation Level: Consider options like remote control operation, automated clamping sequences, and integration with factory automation systems (e.g., interfacing with AGVs or overhead cranes via PLC communication). Industry 4.0 trends emphasize connectivity and data exchange.

7. Operational Safety Features and Compliance

Safety is non-negotiable. Modern mold tilters should incorporate multiple layers of protection.

- Standard Features: Emergency stop buttons, overload protection, safety interlocks (preventing operation if guards are open or clamps are not secure).

- Advanced Systems: Light curtains, safety scanners, audible/visual alarms during operation.

- Regulatory Compliance: Ensure the machine complies with relevant safety standards (e.g., CE marking in Europe, OSHA guidelines in the US). Ergonomic design, reducing manual strain, is also a critical safety consideration highlighted in occupational health research.

8. Customization and Application-Specific Solutions

Standard models may not fit every unique requirement. Leading manufacturers often provide customization options.

- Tailored Design: Modifications can include specific table dimensions, increased load capacity, unique clamping fixtures for non-standard molds, specialized paint or coatings, or enhanced environmental protection (e.g., for foundry environments).

- Integration: Custom interfaces for integration into fully automated production cells.

9. Maintenance, Reliability, and Technical Support

Long-term performance depends on robust design and available support.

- Design for Maintainability: Assess ease of access to key components (motors, gearboxes, hydraulic units), lubrication requirements, and availability of diagnostic tools.

- Component Quality: High-quality components from reputable suppliers generally translate to higher reliability and reduced downtime.

- Manufacturer Support: Evaluate the manufacturer's reputation for providing timely technical support, readily available spare parts, and comprehensive documentation (maintenance manuals, schematics). Service Level Agreements (SLAs) might be considered for critical operations.

10. Total Cost of Ownership (TCO) and Return on Investment (ROI)

A comprehensive evaluation extends beyond the initial purchase price.

- TCO Factors: Include initial cost, installation, energy consumption, routine maintenance, spare parts, potential downtime costs, and operator training.

- ROI Calculation: Quantify the benefits: reduced mold changeover time, improved worker safety (lowered injury costs), damage prevention to molds, increased production uptime. A higher initial investment in a reliable, efficient, and safe machine often yields a lower TCO and faster ROI, a point frequently emphasized in capital equipment investment analysis.

Strategic Implications in Modern Manufacturing

Investing in an advanced 180-degree mold tilter is not merely an equipment purchase; it's a strategic decision impacting core manufacturing metrics. These machines directly support:

- Lean Manufacturing: By reducing setup times (SMED - Single-Minute Exchange of Die principles) and improving workflow.

- Workplace Ergonomics: Significantly mitigating risks of musculoskeletal disorders associated with manual mold handling, aligning with occupational health best practices.

- Asset Protection: Minimizing the risk of damage to expensive molds during handling and maintenance.

- Industry 4.0 Readiness: Models with advanced controls and connectivity can integrate into smart factory ecosystems, providing operational data and enabling remote monitoring or control.

Conclusion: Making an Informed Investment

Selecting the right 180-degree mold tilter requires a meticulous assessment of your specific operational needs against the capabilities and features of available models. Prioritizing load capacity, safety systems, drive mechanism suitability, operational efficiency, and long-term reliability is crucial. While initial cost is a factor, the Total Cost of Ownership (TCO) provides a more accurate measure of long-term value.

Engaging with reputable manufacturers, discussing customization possibilities, and understanding the available technical support are vital steps. A well-chosen mold tilter is a powerful asset that enhances productivity, ensures operator safety, and protects valuable tooling, ultimately contributing significantly to the bottom line.

For further information or specific application inquiries, please contact info@fhopepack.com