Enhancing Steel Wire Packaging: A Deep Dive into Automatic Coiling & Strapping Machinery

Steel wire production demands precision not just in manufacturing, but critically in packaging. Meeting stringent customer specifications for coil dimensions, weight, and securement requires robust, automated solutions. An automatic steel wire coiling and strapping machine addresses these needs head-on, transforming a labor-intensive process into a streamlined, efficient operation. This technology precisely re-winds steel wire to predetermined lengths, forms stable coils, and automatically secures them with PP (Polypropylene) or PET (Polyethylene Terephthalate) straps, creating packages ready for shipment or downstream processing. Whether integrated seamlessly into a continuous production line or operating offline fed by wire drums, these machines are pivotal in boosting productivity, ensuring package integrity, and reducing operational costs.

Understanding the technical capabilities, operational nuances, and integration potential of this equipment is key for manufacturers aiming to optimize their wire handling processes. Let's explore the design, components, specifications, and real-world benefits of automated steel wire coiling and strapping systems.

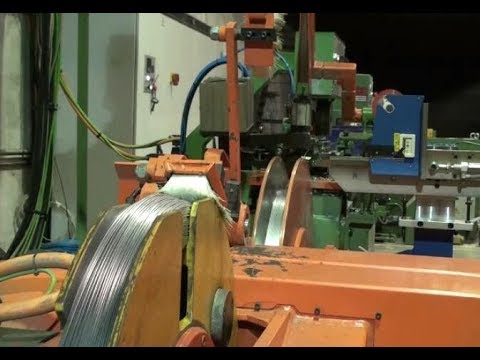

1. Core Functionality: How the Machine Operates

At its heart, the automatic coiling and strapping machine performs a sequence of precise actions:

- Payoff and Tension Control: Wire is fed from a source (e.g., extruder line, payoff drum). A tension control system ensures consistent wire tension during winding, crucial for forming stable, uniform coils and preventing wire damage or tangling.

- Precision Length Measurement: Integrated sensors (often rotary encoders) accurately measure the wire length as it feeds into the coiling head, ensuring each coil meets the exact specified length.

- Automated Coiling: The wire is wound onto a coiling head or drum. The machine controls the winding pattern and speed to achieve the desired coil dimensions (Inner Diameter - ID, Outer Diameter - OD, Width).

- Automatic Cutting: Once the target length is reached, an integrated cutting mechanism cleanly severs the wire.

- Coil Transfer (Optional): In many designs, the completed coil is automatically transferred from the coiling station to the strapping station.

- Automated Strapping: One or more strapping heads apply PP or PET straps radially around the coil circumference at pre-set positions. The straps are tensioned, sealed (typically via heat or friction weld), and cut automatically.

- Coil Ejection/Discharge: The finished, strapped coil is automatically ejected onto a conveyor, accumulation table, or stacking system.

steel wire rewinding and strappign machine 2. Key Components and Design Considerations

Understanding the machine's structure helps appreciate its capabilities:

- Payoff Stand: Holds the source wire drum or interfaces with the production line. Can be passive or driven, often incorporating dancers or accumulators for tension management.

- Wire Straightener (Optional): Removes residual cast or kinks from the wire before coiling.

- Tension Control System: Crucial for coil quality. May use dancer arms, load cells, or servo-driven capstans.

- Length Counter: Typically a high-resolution encoder coupled with a measuring wheel. Accuracy is paramount.

- Coiling Head/Winder: The mechanism that forms the coil. Designs vary (e.g., collapsible drum, belt winder) depending on coil size and weight requirements. Must allow easy coil removal.

- Cutting Unit: Pneumatic, hydraulic, or servo-driven shear designed for the specific wire type and diameter range.

- Strapping Head(s): The core of the strapping function. Must be compatible with selected strap type (PP/PET), width, and thickness. Includes mechanisms for strap feeding, tensioning, sealing, and cutting. Multiple heads allow faster strapping cycles.

- Control System (PLC & HMI): The brain of the operation. A Programmable Logic Controller (PLC) manages the sequence, timings, and interlocks. A Human-Machine Interface (HMI) touch screen allows operators to set parameters (length, coil dimensions, strap positions, tension), monitor status, and troubleshoot. Common PLC brands include Siemens, Allen-Bradley, or Mitsubishi.

- Safety Systems: Includes guarding, emergency stops, light curtains, and interlocks to protect operators, complying with relevant safety standards like ISO 13849-1.

Alt text: Close-up of an automated strapping head applying a PET strap to a steel wire coil, showcasing the precision mechanism.

3. Technical Specifications Overview

Performance capabilities vary based on machine design and application. Here are typical specification ranges:

- Wire Diameter Range: 1.0 mm – 8.0 mm (can vary significantly based on machine class)

- Coil Specifications:

- Inner Diameter (ID): 200 mm – 800 mm

- Outer Diameter (OD): 300 mm – 1200 mm

- Coil Width: 50 mm – 500 mm

- Max Coil Weight: 25 kg – 1000 kg (or higher for heavy-duty models)

- Coiling Speed: 50 – 300 meters/minute (dependent on wire diameter and coil handling)

- Length Measurement Accuracy: Typically ± 0.1% to ± 0.5%

- Strapping:

- Strap Type: PP (Polypropylene) or PET (Polyethylene Terephthalate)

- Strap Width: 9 mm, 12 mm, 16 mm, 19 mm (common sizes)

- Strap Thickness: 0.5 mm – 1.2 mm

- Number of Straps per Coil: 2 – 6 (programmable)

- Strapping Cycle Time: 5 – 15 seconds per strap (depends on coil size and head type)

- Control System: PLC with Touch Screen HMI (e.g., 7-10 inch)

- Power Requirements: 380V/480V, 3-Phase, 50/60Hz; Power consumption varies (e.g., 5 kW – 25 kW)

- Pneumatic Requirements: Clean, dry compressed air (e.g., 6-8 bar)

Note: These are typical ranges. Specific machine models will have precise specifications.

4. Operational Workflow and Advanced Features

Beyond basic coiling and strapping, modern machines offer enhanced functionality:

- Online Integration: The machine can be synchronized with upstream equipment (e.g., wire drawing lines, extruders) for continuous, unattended operation. Data communication via protocols like Profinet or Ethernet/IP allows seamless integration.

- Offline Operation: Flexibility to operate standalone, typically fed from large wire drums or spools using a dedicated payoff system. Ideal for processing stored wire or handling specialized orders.

- Automatic Changeover: Advanced models may feature automated adjustments for different wire diameters or coil recipes, minimizing downtime between production runs.

- Data Logging & Reporting: The control system can log production data (coils produced, lengths, weights, fault history) for quality control and OEE (Overall Equipment Effectiveness) analysis.

- Optional Add-ons:

- Weighing: Integrated scale for recording individual coil weight.

- Labeling/Tapping: Automatic application of identification labels or logo tape.

- Stacking: Robotic or mechanical systems to stack finished coils onto pallets.

Alt text: Diagram showing a steel wire coiling machine integrated into an automated packaging line, illustrating online operation capabilities.

5. User Experience and Maintenance Insights

From an operational standpoint, key considerations include:

- Ease of Use: Modern HMIs simplify parameter setting and recipe management. Intuitive interfaces reduce training time.

- Changeover Efficiency: How quickly can operators switch between different wire sizes, coil dimensions, or strap types? This impacts flexibility and productivity, especially in high-mix environments. Look for designs with quick-release tooling or automated adjustments.

- Reliability: Robust construction, high-quality components (bearings, motors, sensors, strapping heads), and effective tension control are crucial for minimizing downtime.

- Maintenance: Regular preventative maintenance is essential. Key areas include lubrication, cutter blade sharpness, strapping head cleaning (especially the sealing area), sensor checks, and pneumatic system checks. Accessibility for maintenance is an important design factor.

- Troubleshooting: Clear diagnostics on the HMI and well-documented manuals are vital for quick problem resolution. Common issues might involve strap feed problems, inconsistent tension, or length inaccuracies, often traceable to setup or maintenance oversights.

6. Benefits of Automation: Efficiency, Quality, and Cost Savings

Investing in automatic coiling and strapping yields significant advantages:

- Increased Throughput: Automation drastically speeds up the coiling and packaging process compared to manual or semi-automatic methods.

- Labor Cost Reduction: Frees up personnel previously needed for manual coiling, strapping, and handling, allowing reallocation to higher-value tasks.

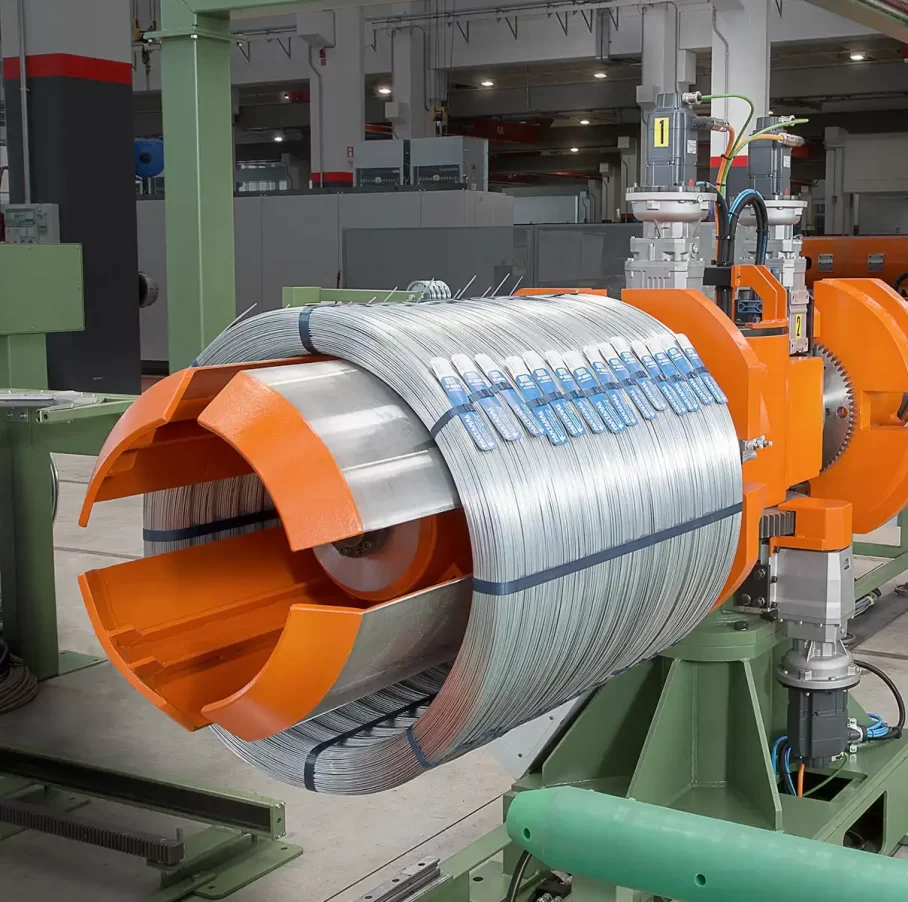

- Improved Package Quality & Consistency: Automated control ensures every coil meets precise length, dimension, and tension specifications. Straps are applied consistently, enhancing package integrity and appearance.

- Material Savings: Precise strapping control minimizes waste of PP or PET strap compared to manual application. Accurate length measurement reduces wire scrap.

- Enhanced Safety: Enclosed automated systems reduce operator exposure to moving machinery and heavy lifting hazards associated with manual coiling.

- Data Integration: Enables better production monitoring, quality tracking, and integration with plant-wide manufacturing execution systems (MES).

Alt text: Neatly strapped steel wire coils stacked uniformly, demonstrating efficient material use and high package quality achieved through automation.

7. Choosing the Right System: Semi-Auto vs. Full-Auto

While full automation offers maximum efficiency, semi-automatic options exist. These typically automate the coiling but require manual strap insertion or coil removal. The choice depends on:

- Production Volume: High volumes generally justify full automation.

- Budget: Fully automatic lines represent a higher initial investment.

- Product Mix: Frequent changeovers might favor systems designed for flexibility, whether semi or fully automatic.

- Labor Availability and Cost: Local labor dynamics influence the ROI calculation for automation.

Both semi-automatic and fully automatic options provide significant improvements over purely manual methods, offering pathways to enhanced efficiency and cost-effectiveness tailored to specific operational needs.

In conclusion, automatic steel wire coiling and strapping machines are sophisticated systems vital for modern wire manufacturing and processing. By delivering precision, speed, consistency, and integration capabilities, they provide a powerful solution for creating high-quality, securely packaged wire products while optimizing operational efficiency and reducing costs. Evaluating the technical specifications, operational features, and integration potential against specific production requirements is crucial for selecting the right system to meet today's demanding market needs.