Optimizing Steel Wire Packaging: A Deep Dive into FHOPE's Automatic Coil Winding and Strapping Systems

In the demanding world of steel wire production, efficient and reliable downstream packaging is paramount. Manual or semi-automated processes often introduce bottlenecks, inconsistencies, and safety concerns. FHOPE, a leading manufacturer specializing in steel wire coil winding and strapping machines, provides advanced, fully automated solutions designed to address these challenges head-on, enhancing productivity and ensuring package integrity for diverse steel wire applications.

1. The Challenge: Inefficiencies in Traditional Wire Coil Handling

Traditional methods for coiling and securing steel wire often involve significant manual labor, leading to:

- Inconsistent Coil Quality: Variations in winding tension and dimensions.

- Low Throughput: Manual handling limits production speed.

- Labor Intensity: High reliance on operators for repetitive tasks.

- Safety Risks: Potential for injuries during handling and strapping.

- Material Waste: Improper strapping or handling can lead to damaged products.

Addressing these issues requires a move towards sophisticated automation, precisely where FHOPE's technology excels.

2. FHOPE's Automated Solution: An Integrated Approach

FHOPE designs and manufactures fully automatic steel wire coil winding and strapping lines that seamlessly integrate these two critical processes. This system is engineered for continuous operation, minimizing manual intervention and maximizing efficiency from the take-up stage to the final strapped coil ready for dispatch.

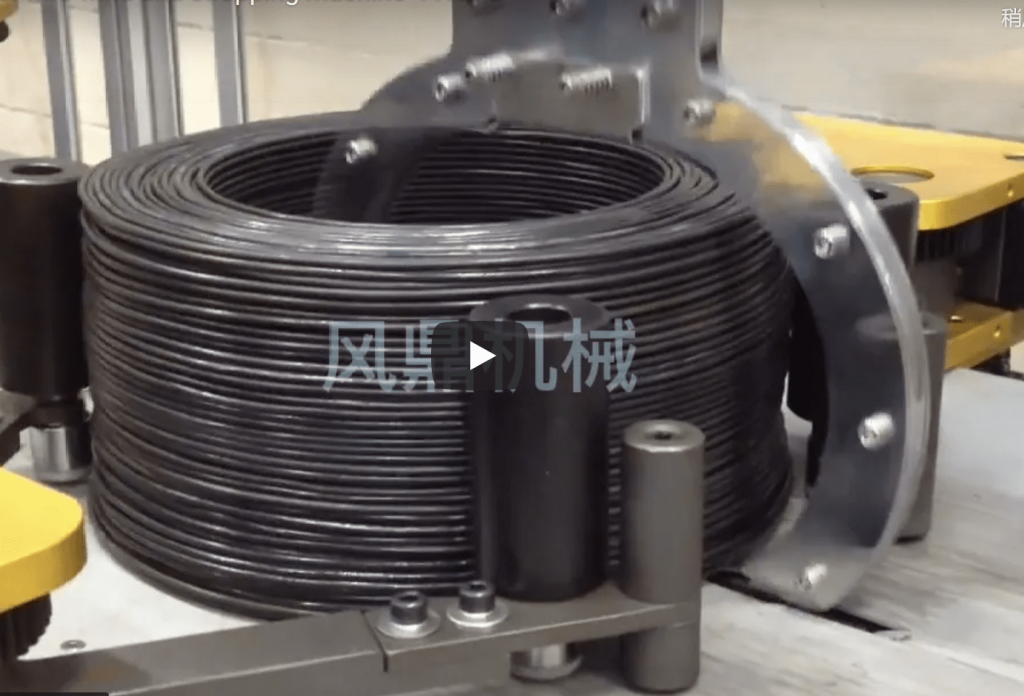

(Image: [Insert relevant image of the FHOPE machine or production line here] Alt Text: FHOPE Automatic Steel Wire Coil Winding and Strapping Machine in operation)

3. Core Functionality: Precision Winding Meets High-Speed Strapping

The effectiveness of the FHOPE system lies in the precision and synchronization of its core components:

3.1 Precision Winding Technology

- Accurate Coil Formation: Utilizes advanced controls (often PLC-based with servo drives) to ensure consistent wire layering and precise coil dimensions (ID/OD/Width) according to pre-set parameters.

- Tension Control: Sophisticated tension control systems maintain uniform tension throughout the winding process, crucial for coil stability and preventing wire damage.

- Programmable Parameters: Operators can easily set and adjust winding specifications via an intuitive Human-Machine Interface (HMI) for different wire types and customer requirements.

3.2 High-Speed Strapping System

- Automated Coil Handling: The system automatically transfers the finished coil from the winder to the strapping station.

- Multiple Strapping Options: Configurable for applying multiple radial straps (typically 3 or 4) using PET or steel strapping material, ensuring coil security for handling and transport.

- Reliable Strapping Heads: Employs robust and high-speed strapping heads for consistent tensioning, sealing (friction weld for PET or seals for steel), and cutting.

- Indexing Accuracy: Precisely rotates the coil for accurate strap placement at desired intervals.

4. Technical Specifications & Design Deep Dive

Understanding the technical capabilities highlights the system's suitability for various industrial environments.

4.1 Key Performance Indicators (Typical Ranges):

| Parameter | Specification | Notes |

|---|---|---|

| Wire Diameter Range | 1.0 mm - 16.0 mm (Typical) | Customizable based on application |

| Max Coil Weight | Up to 2500 kg (Model dependent) | Varies significantly with machine size |

| Coil ID Range | 300 mm - 800 mm | Adjustable fixtures |

| Coil OD Range | 500 mm - 1500 mm | Dependent on wire diameter and weight |

| Coil Width Range | 50 mm - 600 mm | Adjustable during winding |

| Winding Speed | Variable, up to 200 m/min | Dependent on wire size and line speed |

| Strapping Speed | 15 - 30 seconds per coil (3 straps) | Includes transfer, indexing, strapping |

| Strapping Material | PET (Polyester) or Steel | Specify head type based on requirement |

| Strap Width | 12 mm, 16 mm, 19 mm (Common) | Matched to strapping head |

| Control System | PLC (e.g., Siemens, Allen-Bradley) | HMI for operation and diagnostics |

Note: These are representative values. FHOPE provides customized machines tailored to specific client requirements.

4.2 Structural Design and Components

- Robust Frame: Constructed from heavy-duty steel for stability and longevity in industrial settings.

- Quality Components: Utilizes internationally recognized brands for key components like PLCs, drives, sensors, and pneumatic systems to ensure reliability and ease of maintenance.

- Safety Integration: Comprehensive safety features, including guarding, emergency stops, and light curtains (optional), comply with relevant safety standards.

4.3 Customization Capabilities

FHOPE distinguishes itself by offering custom coil winding equipment. This includes:

- Adapting machine dimensions to fit existing plant layouts.

- Integrating specialized sensors for quality control.

- Handling unique wire profiles or materials.

- Developing specific coil handling solutions (e.g., tilting, conveying, palletizing).

5. Operational Advantages and User Experience

Implementing an FHOPE automatic system delivers tangible benefits:

5.1 Enhanced Productivity and Efficiency

- Increased Throughput: Continuous, automated operation significantly boosts the number of coils processed per shift compared to manual methods.

- Reduced Cycle Times: Streamlined workflow minimizes delays between winding, transfer, and strapping.

- Consistent Output: Automation eliminates human variability, ensuring every coil meets specification.

5.2 Improved Safety and Reduced Labor

- Minimized Manual Handling: Reduces operator exposure to heavy lifting and repetitive motions associated with manual coiling and strapping.

- Safer Work Environment: Enclosed guarding and automated processes lower the risk of accidents.

- Labor Reallocation: Frees up personnel for higher-value tasks.

5.3 User Interface and Control

- Intuitive HMI: Touchscreen panels provide easy access to machine settings, recipe management, real-time status monitoring, and diagnostics.

- Ease of Operation: Simplifies parameter adjustments for different product runs.

5.4 Reliability and Maintenance Considerations

- Designed for Durability: Robust construction and quality components minimize downtime.

- Accessible Design: Considerations for ease of access for routine maintenance and component replacement.

(Image: [Insert relevant image of the HMI screen or control panel] Alt Text: User-friendly HMI panel on the FHOPE steel wire packaging machine)

6. Integration and Versatility

FHOPE's steel wire handling solutions are designed for flexibility:

- Line Integration: Can be seamlessly integrated with upstream wire drawing or processing lines and downstream conveying or palletizing systems.

- Material Adaptability: Capable of handling various types of steel wire, including low/high carbon steel wire, galvanized wire, PC strand, and more.

7. Conclusion: Investing in Automated Steel Wire Packaging

FHOPE's automatic steel wire coil winding and strapping machines represent a significant advancement for steel wire manufacturers seeking to optimize their packaging operations. By combining precision engineering, robust construction, customization capabilities, and intelligent automation, these systems deliver enhanced productivity, improved coil quality, greater operational safety, and a strong return on investment. For companies looking to streamline their steel wire processing and packaging workflow, exploring FHOPE's tailored solutions is a crucial step towards achieving competitive advantage.

For more information or to discuss your specific steel wire coil packaging requirements, contact FHOPE directly.