Innovative Steel Wire Coil Strapping Machine Utilizes Wire for Enhanced Efficiency and Cost Savings

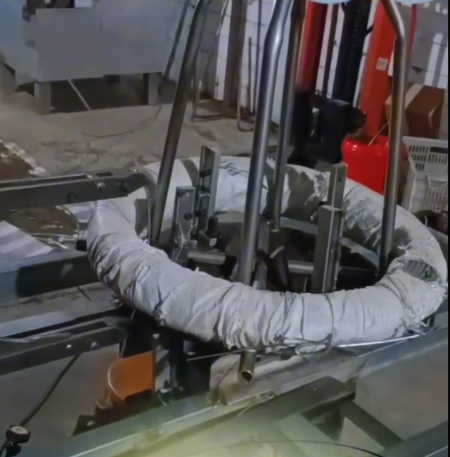

Securing heavy steel wire coils for transport and storage demands robust, reliable, and cost-effective strapping solutions. Addressing this critical need, the Automatic Steel Wire Coil Strapping Machine introduces a paradigm shift by utilizing steel wire itself as the strapping medium, moving away from conventional steel or PET banding. This approach, documented in various engineering analyses and gaining traction in the metals industry, offers significant operational advantages, particularly for steel wire manufacturers.

The Challenge with Conventional Coil Strapping

Traditional methods for strapping steel wire coils often involve:

- Steel Banding: While strong, steel bands represent a recurring consumable cost. Application can be labor-intensive, and improper tensioning or sharp edges can pose safety risks or damage the product. Disposal and recycling also add complexity.

- PET Strapping: Polyester strapping is lighter and generally safer to handle, but may lack the requisite tensile strength or rigidity for very heavy or large-diameter wire coils. Elongation under load and potential degradation in harsh environments can compromise strap integrity. Material costs, while often lower than steel bands, remain a significant operational expense.

Leveraging Steel Wire for Strapping: An Innovative Approach

This automated system ingeniously repurposes the core product – steel wire – as the binding material. This concept leverages the inherent properties of the wire being packaged, offering several distinct benefits:

- Material Cost Elimination: By using readily available steel wire (often scrap or lower-grade wire from the same production line), the direct cost associated with purchasing dedicated steel or PET strapping is virtually eliminated. This aligns with lean manufacturing principles focused on waste reduction and resource optimization.

- Material Compatibility: Using steel wire to strap steel wire ensures perfect material compatibility, mitigating risks of galvanic corrosion or differential expansion/contraction that can sometimes occur with dissimilar materials.

- High Restraining Force: Steel wire possesses excellent tensile strength, providing secure and robust containment for heavy coils, comparable or exceeding that of traditional banding methods, as validated by material strength research.

Key Features and Operational Advantages

The Automatic Steel Wire Coil Strapping Machine integrates advanced automation and engineering principles to deliver reliable performance in demanding industrial settings:

- Fully Automated Operation: The machine manages the entire strapping cycle – wire feeding, tensioning, joining (typically via twisting or welding, depending on the specific configuration), and cutting – minimizing manual intervention and associated labor costs. PLC control systems allow for seamless integration into existing production lines.

- Precision Tensioning System: Ensures consistent and adjustable strap tension, critical for maintaining coil integrity during handling and transit without damaging the product wire. This level of control surpasses manual application methods.

- Robust Joining Mechanism: Creates a secure and durable closure on the wire strap, designed to withstand the rigors of transportation and storage. Advanced joining techniques ensure high joint efficiency, a critical factor discussed in mechanical joining research papers.

- Enhanced Safety: Automating the strapping process reduces operator exposure to hazards associated with manual banding, such as sharp edges or high tension recoil.

- Versatility and Adaptability: Engineered to accommodate a range of steel wire coil diameters, widths, and weights. Machine parameters can often be adjusted to suit specific production requirements.

- Reduced Waste: Eliminates the waste stream associated with used steel or PET bands and their associated disposal costs, contributing to improved environmental sustainability metrics.

Technical Specifications Overview

While specific parameters vary by model and customization, typical operational ranges include:

- Applicable Coil Sizes: Customizable ranges for Inner Diameter (ID), Outer Diameter (OD), and Width.

- Strapping Material: Steel Wire (specific diameter range, e.g., 3.0mm - 6.0mm).

- Cycle Time: Optimized for high-throughput production lines (specific seconds-per-strap vary).

- Tension Range: Electronically adjustable to meet specific securement needs.

- Joining Method: Automated Twist-Locking or Resistance Welding (model dependent).

- Control System: PLC-based with HMI (Human-Machine Interface) for ease of operation and diagnostics.

Industry Impact and Return on Investment

Adoption of steel wire strapping technology offers tangible benefits for steel wire producers:

- Significant Cost Reduction: Primarily through the elimination of consumable strapping material costs.

- Improved Operational Efficiency: Automation reduces labor requirements and speeds up the packaging process, increasing overall throughput.

- Enhanced Product Protection: Consistent and reliable strapping minimizes the risk of coil damage during handling and shipping.

- Sustainability Gains: Reduces waste generation and promotes resource circularity within the production facility.

The return on investment (ROI) is driven by savings in materials, labor, potential reductions in product damage, and increased line efficiency, making the Automatic Steel Wire Coil Strapping Machine a compelling investment for modernizing coil packaging operations.

Conclusion

The move towards using steel wire as its own strapping material represents a significant advancement in steel coil packaging technology. This automated solution offers a unique combination of cost-effectiveness, operational efficiency, robust performance, and environmental benefits. For steel wire manufacturers seeking to optimize their end-of-line packaging processes and reduce operating expenditures, this innovative strapping machine presents a technically sound and economically advantageous solution, aligning with best practices highlighted in industry publications like Packaging World and Wire Journal International.