Optimizing End-of-Line Efficiency: A Deep Dive into Automated Steel Tube Bundle Stacking and Strapping Lines

In today's competitive metal fabrication landscape, optimizing every stage of production is paramount. While significant focus is often placed on cutting, bending, and welding processes, the end-of-line handling – specifically the stacking, bundling, and strapping of finished steel tubes and pipes – presents a critical opportunity for efficiency gains, cost reduction, and safety improvements. Manual or semi-automated handling methods are often labor-intensive, slow, prone to inconsistencies, and pose potential safety risks to personnel. Automated steel tube bundle stacking and strapping lines offer a sophisticated solution to these challenges.

This article delves into the design, components, operational workflow, and tangible benefits of implementing such automated systems, providing valuable insights for fabricators seeking to enhance their downstream operations.

1. The Bottleneck: Challenges in Traditional Tube Handling

Before exploring the automated solution, it's essential to understand the limitations of conventional methods:

- Labor Intensity: Manually collecting, arranging, and strapping tubes requires significant manpower, diverting skilled labor from other value-added tasks.

- Inconsistent Bundle Quality: Achieving consistently tight, uniform, and stable bundles (especially hexagonal shapes for optimal packing) manually is difficult and operator-dependent.

- Low Throughput: Manual processes inherently limit the speed at which finished tubes can be packaged, potentially creating bottlenecks that slow down the entire production line.

- Safety Concerns: Handling heavy steel tubes manually increases the risk of strains, crush injuries, and other workplace accidents.

- Potential Product Damage: Improper handling can lead to scratches, dents, or deformation of finished tubes.

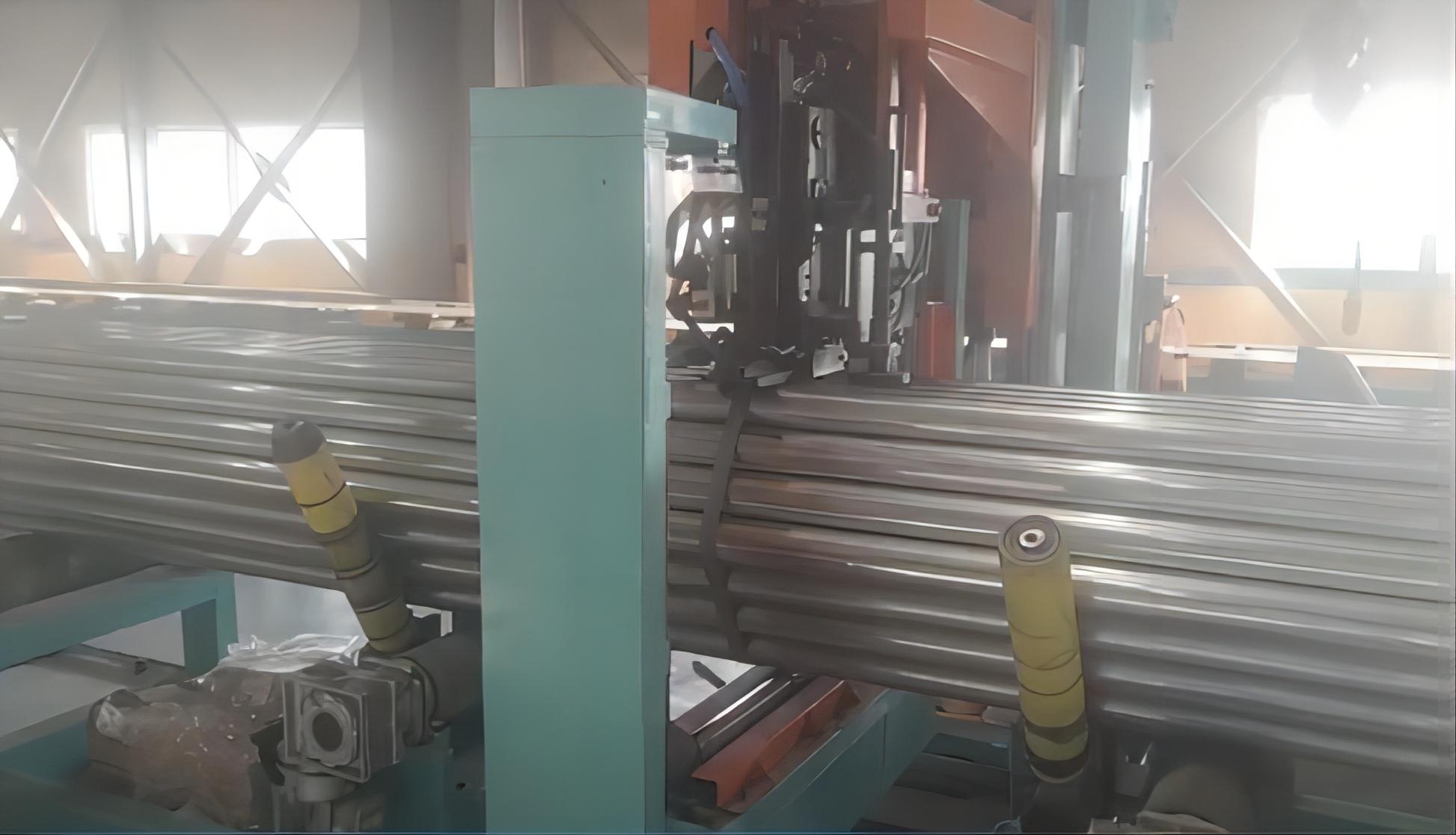

steel tube bundle strapping line 2. Anatomy of an Automated Stacking and Strapping Line

An automated system integrates several key modules working in concert to transform loose tubes into securely strapped bundles ready for storage or shipment. While specific configurations vary based on application requirements, typical core components include:

- Infeed System: Conveyors (roller or belt type) receive finished tubes from the preceding process (e.g., tube mill, cutting station) and transport them towards the collection area. Sensors often track tube arrival.

- Tube Collection and Counting: A mechanism, often involving escapements or gates, collects a predetermined number of tubes required for a single layer or the complete bundle. Precision counting ensures bundle consistency.

- Layer Formation / Pre-Stacking: Tubes are arranged into a specific layer configuration (e.g., a flat row). This may involve guides or pushers.

- Bundle Formation Unit: This is the heart of the stacking process. It often utilizes:

- Lifting Arms/Carriages: To pick up formed layers.

- Shaping Jigs/Nests: Typically V-shaped or specifically contoured plates that guide tubes into the desired bundle shape (commonly hexagonal for round tubes, offering high density and stability). Clamps may temporarily secure the layers during formation.

- Vertical Stacking Mechanism: Layers are incrementally added and lowered or raised to build the complete bundle within the shaping jig.

- Strapping Integration: Once the bundle is formed, it's transferred or indexed to the strapping station(s).

- Strapping Heads: Automated heads feed, tension, seal (usually via heat or friction weld for PET straps, or crimping for steel straps), and cut the strap. Multiple heads may operate simultaneously for faster cycle times or securement at different points along the bundle length.

- Strap Dispenser: Holds large coils of PET (polyester) or steel strapping material.

- Bundle Outfeed/Ejection: Once strapping is complete, the finished bundle is discharged from the machine onto an outfeed conveyor, rollers, or a designated collection area, ready for removal by forklift or crane.

- Control System: A Programmable Logic Controller (PLC) orchestrates the entire sequence, receiving input from sensors and controlling motors, actuators, and the strapping heads. A Human-Machine Interface (HMI) provides operator controls, system status display, diagnostics, and recipe management (for different tube sizes and bundle configurations).

3. Key Technical Specifications & Performance Data Comparison

When evaluating automated tube bundling systems, several technical parameters are crucial. Below is a representative comparison table illustrating typical ranges – actual specifications depend heavily on the manufacturer and specific application needs:

| Feature | Typical Range (System A - Medium Duty) | Typical Range (System B - Heavy Duty) | Unit | Notes |

|---|---|---|---|---|

| Tube Diameter Range | 20 - 90 | 50 - 160 | mm | Or equivalent square/rectangular dimensions |

| Tube Length Range | 3 - 6 | 4 - 12 | meters | Longer lengths often require additional support |

| Bundle Shape | Hexagonal, Square | Hexagonal, Square, Rectangular | - | Hexagonal is common for round tubes |

| Max. Bundle Weight | 1,500 | 3,000+ | kg | Dependent on structure and handling capacity |

| Cycle Time (Approx.) | 60 - 90 | 90 - 180 | seconds/bundle | Varies greatly with bundle size & complexity |

| Strapping Material | PET | PET or Steel | - | PET is common; Steel for very heavy bundles |

| Strap Width | 12 - 19 | 16 - 32 | mm | |

| Number of Straps/Bundle | 2 - 4 | 2 - 6+ | - | Programmable |

| Automation Control | Siemens / Allen-Bradley PLC | Siemens / Allen-Bradley PLC | - | HMI Touchscreen Standard |

| Power Requirements | 480V/3Ph/60Hz (Varies) | 480V/3Ph/60Hz (Varies) | - | Check specific machine requirements |

| Estimated Footprint (LxW) | 10m x 5m | 15m x 7m | meters | Highly variable based on configuration |

Note: This data is illustrative. Always consult manufacturer specifications for accurate details.

4. Operational Workflow: From Loose Tubes to Secured Bundle

The process, as visualized in the video and typical of these systems, generally follows these steps:

- Tube Arrival: Tubes exit the production line onto the infeed conveyor.

- Counting & Collection: Sensors count the tubes as they arrive; gates release the correct number for a layer/bundle into the formation area.

- Layer Formation: Tubes are arranged side-by-side.

- Stacking & Shaping: Layers are lifted and placed into the bundling jig, forming the hexagonal (or other) shape incrementally.

- Bundle Transfer: The complete, unstrapped bundle is indexed or transferred to the strapping position(s).

- Automatic Strapping: Strapping heads cycle – feeding strap around the bundle, tensioning to a pre-set level, sealing the strap, and cutting it. This repeats for the required number of straps along the bundle length.

- Bundle Ejection: The secured bundle is moved onto the outfeed conveyor or holding area.

- System Reset: The bundling and strapping stations reset, ready for the next cycle.

5. Quantifiable Benefits: Why Automate?

Investing in an automated stacking and strapping line yields significant operational advantages:

- Increased Throughput: Dramatically faster cycle times compared to manual methods, eliminating end-of-line bottlenecks.

- Consistent Bundle Integrity: Precise counting and automated shaping ensure every bundle is uniform, stable, and securely strapped according to specifications.

- Enhanced Safety: Removes operators from the hazards of manually lifting, positioning, and strapping heavy steel tubes. Reduces risk of repetitive strain and other injuries.

- Reduced Labor Costs: Frees up personnel previously assigned to manual bundling for more skilled tasks, optimizing labor allocation.

- Minimized Product Damage: Gentle, controlled handling reduces the likelihood of scratches, dents, or deformation during the packaging process.

- Improved Floor Space Utilization: Automated lines can often be designed with a more compact and efficient footprint compared to sprawling manual stations.

- Data Logging & Traceability: Advanced control systems can log production data (bundle counts, cycle times, faults) for process monitoring and quality control.

6. Integration and Considerations for Implementation

Successfully implementing an automated bundling line requires careful planning:

- Upstream/Downstream Integration: Ensure seamless flow from the tube production/cutting line and efficient removal of finished bundles (e.g., forklift access, crane interface).

- Product Variability: The system must accommodate the range of tube diameters, lengths, wall thicknesses, and desired bundle configurations.

- Strapping Material Choice: PET is often preferred for its cost-effectiveness, safety (no sharp edges), and ability to retain tension, but steel may be necessary for extremely heavy or rigid bundles.

- Space and Layout: Assess available floor space, ceiling height, and access requirements for installation and maintenance.

- Customization: Work with system suppliers to tailor the line's features (e.g., number of strapping heads, specific jigging, control system options) to your specific needs.

- Operator Training: While automated, personnel still require training for operation, basic troubleshooting, and safety procedures.

7. Operator Perspective: Day-to-Day Interaction

From an operational standpoint, interacting with a well-designed automated line is often straightforward. Operators typically use the HMI touchscreen to:

- Select pre-programmed recipes for different tube sizes and bundle types.

- Monitor the system's status, viewing cycle progress and sensor inputs.

- Acknowledge alarms or faults, often guided by diagnostic messages on the HMI.

- Initiate manual movements for maintenance or setup purposes.

- Replenish strapping material.

Operators often report significant improvements in workplace ergonomics and a reduction in physically demanding tasks. The consistency of the machine's output also simplifies quality checks and downstream handling. Reliability and ease of troubleshooting are key factors contributing to operator satisfaction and overall system uptime.

Conclusion: A Strategic Investment in Efficiency

Automated steel tube bundle stacking and strapping lines represent a significant step forward from manual methods. By integrating robust mechanical design, precise automation controls, and reliable strapping technology, these systems directly address key challenges in end-of-line handling. The resulting improvements in throughput, bundle quality, worker safety, and labor efficiency provide a compelling return on investment for forward-thinking steel tube and pipe fabricators aiming to streamline operations and maintain a competitive edge in the demanding metals industry. Evaluating your current processes and exploring the potential of automation in this area is a worthwhile endeavor for any facility handling significant volumes of tubular products.