Optimizing Long Product Packaging: A Deep Dive into FHOPE's Semi-Auto Orbital Wrapping Machine

Wrapping long, bulky, or irregularly shaped items like pipes, profiles, timber, or bars presents unique challenges in industrial packaging. Ensuring product protection, load stability, and operational efficiency requires specialized equipment. FHOPE's semi-automatic orbital wrapping machine offers a targeted solution, designed specifically for these demanding applications. Let's explore its technology, benefits, and operational aspects in detail.

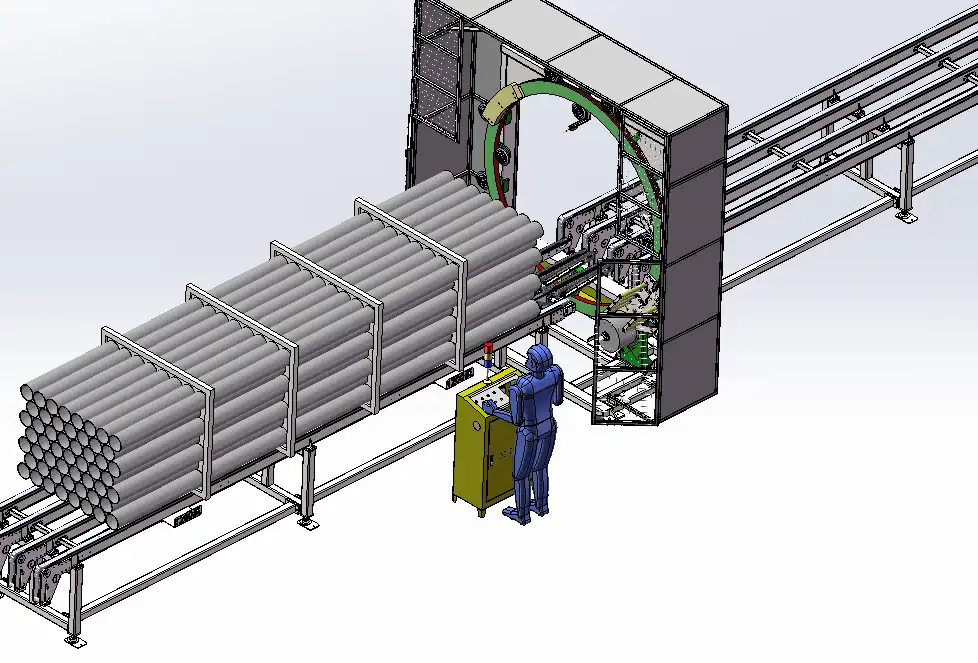

1. Understanding the Technology: How the Semi-Auto Orbital Wrapper Works

Unlike traditional turntable stretch wrappers, an orbital wrapper (also known as a horizontal stretch wrapper) operates differently. The core components include:

- Rotating Ring: A large ring holds the stretch film roll and carriage.

- Film Carriage: This mechanism dispenses the stretch film and controls the tension.

- Conveyor System (or Manual Feed): The product moves horizontally through the rotating ring.

In a semi-automatic operation, the process typically involves:

- The operator manually places the long product onto the infeed conveyor or support rollers.

- The operator initiates the wrapping cycle via a control panel or foot switch.

- The ring rotates around the stationary or slowly moving product, applying the stretch film helically along its length.

- Once the product is fully wrapped, the operator manually cuts the film (unless equipped with auto-cut) and removes the product.

This semi-automatic approach strikes a balance between automation efficiency and operator control, making it suitable for varied production volumes.

2. Key Technical Specifications and Features

While specific configurations vary, typical parameters for a FHOPE semi-auto orbital wrapper include:

- Ring Speed: Adjustable, often ranging from 20 to 60 RPM, dictating wrapping speed.

- Wrapping Material: Primarily designed for LLDPE (Linear Low-Density Polyethylene) stretch film. Common widths might be 100mm, 250mm, or 500mm depending on the model and application.

- Maximum Product Dimensions: Critical specifications defining the maximum cross-section (e.g., 500x500mm, 800x800mm) and length (often theoretically unlimited, practically determined by conveyor/support setup) the machine can handle.

- Control System: Typically user-friendly controls for adjusting ring speed, conveyor speed (if applicable), wrap tension, and overlap.

- Film Tension Control: Mechanical or electronic systems to ensure consistent film stretch and load containment.

- Power Requirements: Standard industrial power supply (e.g., 380V/50Hz/3Ph, customizable).

- Optional Enhancements:

- Automatic Film Cut & Clamp: Automates the start and end of the wrapping cycle, boosting efficiency.

- Top Presser Units: Pneumatic or mechanical devices to stabilize lighter or unstable loads during wrapping.

- Infeed/Outfeed Conveyors: Powered or gravity rollers for easier product handling.

3. Practical Applications and Enhanced Benefits

The FHOPE semi-auto orbital wrapper proves invaluable across various industries:

- Metals: Wrapping aluminum extrusions, steel bars, copper pipes, bundles of profiles.

- Plastics: Securing PVC pipes, conduits, plastic profiles.

- Wood: Packaging timber beams, mouldings, flooring planks.

- Building Materials: Bundling insulation panels, door/window frames.

- Textiles: Wrapping rolls of fabric or carpet.

Compared to manual wrapping or basic strapping, this machine offers significant advantages:

- Superior Protection: Provides a complete, tight wrap shielding products from dust, moisture, scratches, and handling damage during transit and storage.

- Improved Load Stability: Securely unitizes bundles or single long items, preventing shifting and potential damage.

- Operational Efficiency: Drastically reduces the time and labor required compared to manual wrapping. Ensures consistent wrap quality cycle after cycle.

- Material Savings: Optimized film stretching ensures efficient material usage, often reducing film consumption compared to manual methods.

- Enhanced Operator Safety: Minimizes the physical strain and repetitive motions associated with manually wrapping large or heavy items.

4. Operational Insights and User Experience

From personal observation and user feedback, operating a semi-automatic orbital wrapper like those from FHOPE is generally straightforward:

- Ease of Use: The controls are typically intuitive, allowing operators to quickly learn how to adjust settings for different product types. Film roll changes are designed to be relatively simple.

- Flexibility: Adjusting for different product lengths is usually seamless. Adapting tension and overlap for varying protection needs is easily done via the control panel.

- Maintenance: Routine maintenance is generally limited to cleaning sensors, checking roller conditions, and ensuring the film carriage mechanism is functioning smoothly.

The semi-automatic nature means the operator remains involved, allowing for visual inspection and immediate intervention if needed, which can be beneficial for variable product flows or quality checks.

5. Choosing the Right Configuration

Selecting the appropriate semi-auto orbital wrapper depends on:

- Product Characteristics: Maximum dimensions (width, height), weight, and stability.

- Throughput Requirements: Number of pieces or bundles needing wrapping per hour/shift.

- Protection Level: Need for full encapsulation vs. basic bundling.

- Budget: Balancing initial investment against long-term labor and material savings.

- Available Options: Deciding if features like automatic film cutting or powered conveyors are necessary for your specific workflow.

Conclusion

FHOPE's semi-auto orbital wrapping machine represents a robust and cost-effective solution for businesses needing to package long or awkward products efficiently and securely. Its combination of specialized technology, user-friendly operation, flexibility, and ability to significantly enhance product protection makes it a smart investment for manufacturers and distributors in sectors dealing with pipes, profiles, timber, and similar items. By automating the most labor-intensive part of the wrapping process, it boosts productivity while ensuring products reach their destination in optimal condition.

For more detailed specifications or to discuss your specific application needs:

https://www.fhopepack.com/Horizontal_wrapping_machine.html

Contact: info@fhopepack.com