Revolutionizing Steel Tube Logistics: Advanced Automated Packaging Solutions

In today's demanding industrial landscape, efficiency, precision, and safety in steel tube handling and packaging are paramount. Driven by growth in construction, manufacturing, and energy sectors, the need for streamlined logistics has spurred significant innovation in automation. Manual packaging processes, often laborious and prone to inconsistencies and safety hazards, are increasingly being replaced by sophisticated automated systems that deliver tangible benefits in productivity and quality assurance. This article delves into the state-of-the-art technologies transforming steel tube packaging, drawing insights from industry practices and technological advancements.

The Imperative for Automation in Steel Tube Handling

Traditional methods of handling and packaging steel tubes involve considerable manual labor, presenting challenges such as:

- Safety Risks: Handling heavy and often long tubes poses ergonomic risks and potential for accidents.

- Inconsistency: Manual bundling, strapping, and wrapping can lead to variations in package integrity and protection.

- Labor Intensity: Significant workforce allocation is required, impacting operational costs.

- Speed Limitations: Manual processes inherently limit throughput compared to automated lines.

Automation directly addresses these challenges, offering a strategic advantage for manufacturers and distributors seeking enhanced operational excellence.

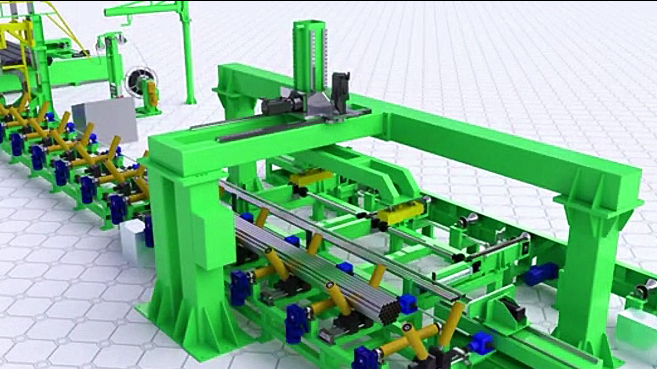

Core Technologies Driving Automated Steel Tube Packaging

Modern automated packaging lines integrate several key technologies, each optimized for specific stages of the process:

Precision Lifting and Collection: Vacuum vs. Electro-Permanent Magnets (EPMs)

The initial collection phase is critical for efficiency and preventing product damage. Two dominant technologies prevail:

- Vacuum Suction Systems: Ideal for handling tubes with smooth, non-porous surfaces, such as stainless steel or aluminum. These systems utilize arrays of suction cups to securely grip and lift tubes. Their effectiveness is well-documented in applications requiring gentle handling to preserve surface finish. However, performance can be sensitive to surface contamination or irregularities.

- Electro-Permanent Magnets (EPMs): Highly effective for ferrous steel tubes, EPMs offer significant advantages. They require power only to switch their magnetic state (ON/OFF) and maintain their holding force indefinitely without continuous electricity consumption, enhancing energy efficiency. Crucially, this provides inherent fail-safe operation, as the load remains securely held even during a power outage. Advanced EPM control systems, often incorporating patented logic, ensure precise magnetic flux control for safe engagement and disengagement, handling varying tube diameters and weights effectively. Industry studies highlight EPMs for their robustness and reliability in heavy-duty material handling.

Automated Counting, Arrangement, and Bundling Systems

Once lifted, tubes are conveyed to the bundling station. The process typically involves:

- Counting & Layer Formation: Sensors (e.g., optical, laser-based) accurately count tubes as they are fed into a collection area. Systems meticulously arrange tubes layer by layer to form the desired bundle shape.

- Bundle Configuration: Sophisticated steel tube packaging machine lines can automatically configure bundles into various profiles – typically square, rectangular, or hexagonal – based on pre-programmed parameters or customer specifications. This precise arrangement optimizes packing density and stability.

- Transfer: The completed layer or bundle is then transferred to the next station (strapping).

High-Integrity Strapping Technologies

Securing the bundle is vital for maintaining its shape and integrity during subsequent handling, storage, and transportation. Key aspects include:

- Strapping Material: Common options are steel straps (for high tensile strength) and Polyethylene Terephthalate (PET) straps (offering good strength, elongation, and resistance to environmental factors). The choice depends on bundle weight, transport conditions, and cost considerations. Research often compares the life-cycle impacts and performance characteristics of these materials in industrial packaging.

- Automated Strapping Heads: These units automatically feed, tension, seal (often via heat welding for PET or crimping for steel), and cut the strap. Advanced systems feature precise tension control, ensuring the bundle is secured tightly without damaging the tubes, particularly crucial for thin-walled or coated products. Compliance with transport regulations (e.g., guidelines similar to those from the Association of American Railroads - AAR) necessitates robust strapping.

Protective Wrapping Solutions

For enhanced protection against environmental factors like moisture, dust, and surface abrasion, bundles are often wrapped:

- Stretch Wrapping: Machines apply layers of stretch film around the bundle. Orbital wrapping machines are commonly used for long products like tubes, ensuring complete coverage. The film provides a barrier against corrosion triggers and physical damage. Studies in corrosion prevention often validate the effectiveness of barrier films in preserving steel product quality during shipping and storage.

- VCI Film Integration: For superior corrosion protection, Vapor Corrosion Inhibitor (VCI) films can be incorporated, releasing molecules that form a protective layer on the metal surface.

Robotic Palletizing and Stacking

The final stage involves preparing bundles for storage or shipment:

- Automated Stacking: Wrapped bundles are transported to a palletizing station. Robotic arms or gantry systems precisely lift and stack the bundles onto pallets according to predefined patterns. This maximizes pallet stability and space utilization in warehouses and during transport.

- System Integration: These palletizing systems are often integrated with upstream processes and downstream Warehouse Management Systems (WMS) for seamless tracking and inventory control. Vision systems can aid in precise placement and quality checks. Safety is paramount, with systems designed according to standards like ISO 10218 (Safety of industrial robots).

- Labeling: Automated labeling units can apply identification tags or labels with barcodes, QR codes, or RFID for tracking and traceability throughout the supply chain.

Quantifiable Benefits and Strategic ROI

Investing in automated steel tube packaging yields significant, measurable advantages:

- Operational Efficiency: Drastic reduction in cycle times and increased throughput, often leading to improvements in Overall Equipment Effectiveness (OEE) cited in manufacturing case studies.

- Labor Optimization: Frees up human resources from repetitive and potentially hazardous tasks, allowing reallocation to more complex, value-added roles. Reduces direct labor costs significantly.

- Enhanced Workplace Safety: Mitigates risks associated with manual lifting and handling of heavy materials, contributing to a safer work environment and reduced insurance premiums.

- Product Quality Assurance: Consistent, high-quality packaging minimizes damage during handling and transit, reducing scrap rates and customer claims. Protection against corrosion preserves product value.

- Supply Chain Velocity: Faster processing and standardized packaging facilitate quicker loading, unloading, and overall logistics flow.

Future Trends: Smarter Packaging Automation

The evolution continues with trends like:

- IIoT Integration: Sensors embedded within the machinery provide real-time data on performance, enabling predictive maintenance and minimizing downtime.

- AI and Machine Learning: Optimizing bundling patterns, strap tension, and robotic movements based on learned data for further efficiency gains.

- Enhanced Vision Systems: Improving quality inspection and guidance for robotic handling.

Conclusion: A Strategic Imperative

Automated steel tube packaging solutions, leveraging technologies from advanced EPM lifting to robotic palletizing, represent a fundamental shift from traditional manual methods. The benefits extend far beyond mere cost savings, encompassing enhanced safety, superior product protection, greater operational flexibility, and improved supply chain performance. As documented in numerous industry reports and case studies, the adoption of these technologies is not just an operational upgrade but a strategic imperative for companies aiming to maintain competitiveness and meet the evolving demands of the global steel market. By embracing automation, steel tube manufacturers and processors can ensure their products are handled, packaged, and delivered with unparalleled efficiency and reliability.