Enhancing Efficiency and Protection: A Technical Look at the Fhopepack Full-Auto Wire Coil Wrapping Machine

In today's demanding industrial landscape, optimizing packaging processes is paramount. For industries dealing with steel wire, cable, or hose coils, ensuring product integrity during transit and storage while maximizing operational efficiency presents a significant challenge. Manual or semi-automatic methods often fall short, leading to inconsistencies, potential product damage, and high labor costs. The Fhopepack Full-Auto Wire Coil Wrapping Machine offers a robust, automated solution designed to address these very issues. This article provides a technical deep dive into its design, components, operational benefits, and user experience.

1. The Challenge: Moving Beyond Manual Coil Packaging

Traditional methods of packaging wire coils often involve manual labor for wrapping with paper, stretch film, or other protective materials. This approach suffers from several drawbacks:

- Inconsistency: Manual wrapping tension and overlap can vary significantly, potentially compromising package integrity.

- Labor Intensity: Requires dedicated personnel, increasing operational costs and diverting resources from other value-added tasks.

- Speed Limitations: Manual processes inherently limit throughput, creating bottlenecks in production or shipping workflows.

- Safety Concerns: Manual handling of heavy coils and wrapping materials can pose ergonomic risks.

Automation is the key to overcoming these hurdles, offering consistency, speed, and reduced reliance on manual intervention.

2. System Overview: The Fhopepack Horizontal Wrapping Solution

The machine featured is a horizontal-type automatic wire coil wrapping machine. This design is particularly suited for stable integration into production lines, allowing coils to be fed and discharged smoothly via integrated power conveyor systems. Its core function is to apply protective layers – typically Kraft paper or VCI paper followed by stretch film – securely around the coil, finishing with an automated taping mechanism for brand reinforcement or sealing.

3. Design Philosophy and Structural Integrity

The Fhopepack machine is engineered with durability and operational reliability in mind:

- Robust Frame: Constructed from heavy-duty steel, ensuring stability and longevity even in demanding industrial environments. The structure is designed to withstand the stresses of continuous operation and heavy coil handling.

- Horizontal Axis Operation: Facilitates easy loading and unloading via conveyors, minimizing manual handling and enabling seamless integration with upstream and downstream processes.

- Modular Components: Key systems like the wrapping ring, conveyor sections, and control panel are designed for accessibility, simplifying maintenance and potential upgrades.

4. Deep Dive into Key Components

Understanding the core components reveals the machine's technical sophistication:

- Powered Conveyor System: Provides automated feeding and unloading of coils. Roller types and spacing can often be customized based on coil dimensions and weight.

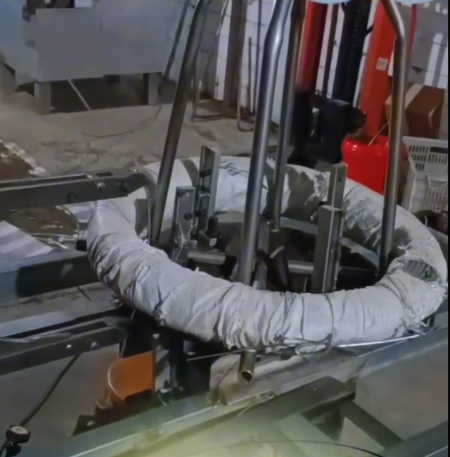

- Wrapping Ring: The heart of the machine. This rotating ring carries the wrapping material dispensers (paper and film) and orbits around the coil as it passes through. Precision engineering ensures smooth rotation and consistent material application.

- Material Dispensers: Separate units for paper (e.g., Kraft, VCI) and stretch film. Equipped with adjustable tension control systems to ensure optimal wrap tightness without damaging the product. Automatic film/paper feeding and cutting mechanisms are standard.

- Automatic Cutting & Clamping: Precisely cuts the wrapping materials upon cycle completion and securely clamps the ends for the next cycle, minimizing waste and ensuring a clean finish.

- Logo Tape Tapping Device: An automated system applies adhesive logo tape at designated points on the wrapped coil, enhancing branding and providing an additional seal.

- PLC Control System: Typically utilizes industry-standard PLCs (e.g., Siemens, Allen-Bradley) with a user-friendly HMI (Human-Machine Interface) touchscreen. Allows operators to set parameters (wrap counts, overlap percentage, conveyor speed), monitor operations, and troubleshoot issues.

5. Technical Specifications Overview

While exact specifications vary based on model and customization, typical parameters include:

- Coil Outer Diameter (OD): 500mm - 1500mm (Example range)

- Coil Inner Diameter (ID): 300mm - 800mm (Example range)

- Coil Width: 100mm - 500mm (Example range)

- Maximum Coil Weight: 100kg - 2000kg (Depending on model)

- Wrapping Ring Speed: 60 - 120 RPM (Adjustable)

- Conveyor Speed: 5 - 15 m/min (Adjustable)

- Wrapping Materials:

- Stretch Film: Width 100-250mm, Thickness 17-35 microns

- Paper/VCI: Width 90-200mm

- Logo Tape: Standard adhesive tape widths

- Control System: PLC + HMI Touchscreen

- Power Supply: 380V/50Hz/3Phase (or customized)

- Air Supply: 0.5 - 0.7 Mpa

Note: These are representative figures. Always consult specific model documentation for precise data.

6. The Automated Wrapping Process: Step-by-Step

The typical operational sequence showcases the machine's efficiency:

- Coil Feeding: The wire coil is automatically transferred onto the infeed conveyor section.

- Positioning: Sensors detect the coil's arrival and position it correctly within the wrapping ring's orbit.

- First Layer Wrapping (Paper): The wrapping ring begins rotating, applying the paper layer with the pre-set overlap and tension. The coil may rotate or remain stationary depending on the configuration.

- Paper Cut & Clamp: Once the required wraps are complete, the paper is automatically cut and clamped.

- Second Layer Wrapping (Stretch Film): The stretch film dispenser engages, applying the film layer over the paper for moisture protection and load stability. The system automatically handles the film tail to prevent unraveling.

- Film Cut & Clamp: The stretch film is cut and clamped upon completion.

- Logo Taping: The automatic tapping device applies the logo tape as programmed.

- Coil Unloading: The wrapped coil is transferred onto the outfeed conveyor for removal or further processing.

7. Quantifiable Benefits and Investment Return

Investing in a Fhopepack automatic wrapping machine delivers tangible advantages:

- Increased Throughput: Significantly faster than manual methods, boosting overall packaging capacity to keep pace with production.

- Reduced Labor Costs: Frees up personnel for other tasks, leading to direct cost savings. The claim of a potential 1-year Return on Investment (ROI) is often achievable, particularly in high-volume operations, due to labor savings and efficiency gains.

- Enhanced Product Protection: Consistent tension and overlap ensure coils are securely wrapped, reducing damage during handling and shipping. The dual-layer (paper + film) approach offers excellent protection against environmental factors and physical abrasion.

- Improved Package Appearance: Uniform wrapping and professional logo taping enhance brand image.

- Operational Consistency: Eliminates variability inherent in manual processes, leading to predictable results.

- Enhanced Safety: Reduces manual handling of heavy coils and repetitive wrapping motions.

8. User Experience and Integration

From a user perspective, the machine is designed for ease of use:

- Intuitive HMI: The touchscreen interface simplifies parameter setting and operational monitoring.

- Accessibility: Key components are designed for straightforward maintenance access.

- Customization: Fhopepack solutions can often be tailored to specific coil sizes, weights, wrapping material requirements, and existing line configurations.

- Integration: Designed to seamlessly integrate into existing production lines, receiving coils directly from production machinery and feeding them into storage or shipping areas.

9. Conclusion: A Strategic Investment in Packaging Automation

The Fhopepack Full-Auto Wire Coil Wrapping Machine represents a significant technological advancement over manual packaging methods. Its robust design, sophisticated components, and automated processes deliver substantial improvements in efficiency, product protection, and operational safety. By providing consistent, high-quality packaging at increased speeds and reduced labor costs, it offers a compelling ROI and serves as a strategic investment for manufacturers and processors in the wire, cable, and related industries seeking to optimize their end-of-line operations.

For more detailed information on tailored wire coil packing solutions: