Revolutionizing Cable Packaging: An In-Depth Look at the Fully Automated Coiling, Strapping, Shrinking, and Palletizing Line

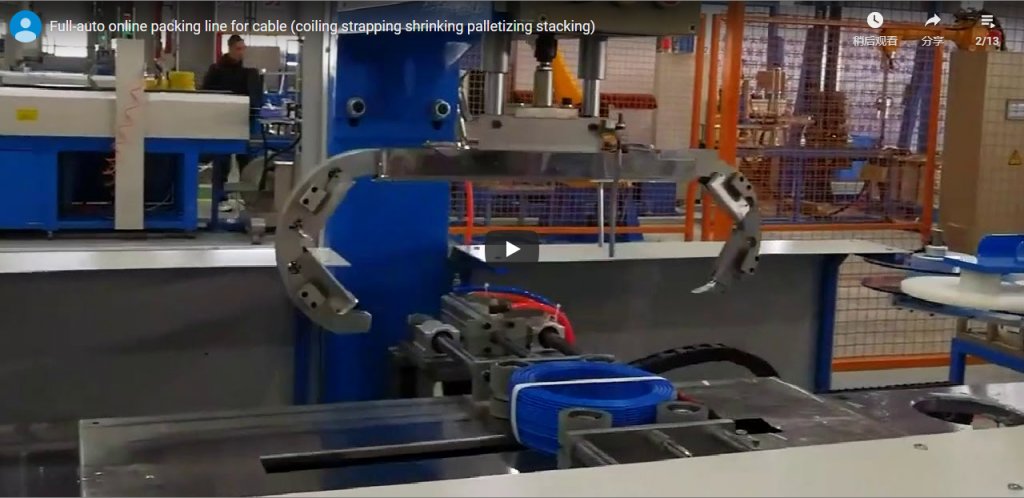

In today's demanding manufacturing landscape, efficiency, consistency, and cost-effectiveness are paramount, especially in high-volume sectors like wire and cable production. Manual or semi-automated end-of-line packaging processes often introduce bottlenecks, inconsistencies, and significant labor costs. This article delves into a comprehensive, fully automated online cable packing solution – integrating coiling, strapping, shrink wrapping, and robotic palletizing – designed to streamline operations and elevate packaging standards. Explore how this integrated system, as showcased in the video above from Fhope Packing Team, transforms cable handling post-extrusion.

1. The Challenge: Overcoming Traditional Packaging Hurdles

Traditional cable packaging methods often face several limitations:

- Labor Intensity: Manual coiling, tying, wrapping, and stacking require significant manpower, leading to high labor costs and potential ergonomic issues.

- Inconsistency: Manual processes can result in variations in coil tightness, strap tension, wrap quality, and pallet stack stability.

- Speed Bottlenecks: Manual or semi-automated steps often struggle to keep pace with modern high-speed extrusion lines, creating production bottlenecks.

- Material Waste: Inconsistent application of strapping or shrink film can lead to material wastage.

- Safety Concerns: Repetitive manual handling of heavy or awkward cable coils poses safety risks.

automatic cable winding and packing line 2000x1500 2. The Solution: Integrated End-of-Line Automation

The Fhopepack full-auto online cable packing line addresses these challenges by seamlessly integrating multiple packaging functions into a single, continuous workflow directly linked to the cable extrusion output. This system comprises several key automated modules operating in perfect synchronization.

3. Core Components & Technical Deep Dive

Let's break down the critical stages and the technology involved:

3.1. Precision Cable Coiling

- Function: Automatically winds extruded cable into neat, specified coils.

- Mechanism: Features a precision winding head and a traversing unit that ensures level layer winding for uniform coil density and shape.

- Control: Servo motors or variable frequency drives (VFDs) control winding speed and tension, synchronizing perfectly with the extrusion line speed. Sensors detect cable presence and diameter for accurate operation.

- Parameters: Coil Inner Diameter (ID), Outer Diameter (OD), and width are precisely controlled and easily adjustable via the Human-Machine Interface (HMI).

3.2. Automated Coil Conveying

- Function: Transports the finished coil from the coiler to the subsequent stations.

- Mechanism: Typically utilizes powered roller or belt conveyors, designed for smooth and stable transfer of coils.

- Integration: Sensors and PLC logic ensure coils are correctly positioned and spaced for the next process (strapping).

3.3. Automatic Strapping Station

- Function: Secures the coil with PP (Polypropylene) belt ties to prevent unwinding.

- Mechanism: An automated strapping head positions the coil, feeds the PP belt around it, tensions the strap to a pre-set level, seals it (often via heat or ultrasonic welding), and cuts the belt.

- Configuration: Can be configured for single, double, or multiple straps per coil depending on coil size and stability requirements.

3.4. Auto Sealing & Shrink Wrapping

- Function: Encloses the strapped coil in a protective film (POF or PE) and shrinks it for a tight, secure, and tamper-evident package.

- Mechanism:

- Sealing: An automatic L-bar sealer or side sealer creates a bag around the coil using center-folded shrink film.

- Shrinking: The bagged coil passes through a heat shrink tunnel where controlled hot air circulation shrinks the film uniformly around the coil contours.

- Film Types: Compatible with Polyolefin (POF) or Polyethylene (PE) shrink films, chosen based on required durability, clarity, and cost.

- Control: Precise temperature and airflow control within the tunnel are crucial for optimal shrink results without damaging the cable insulation.

3.5. Robotic Palletizing & Stacking

- Function: Automatically picks the finished, shrink-wrapped coils and stacks them onto a pallet in a pre-defined pattern.

- Mechanism: Utilizes an industrial robot (e.g., a 4-axis or 6-axis articulated arm) equipped with a custom End-of-Arm Tooling (EOAT) specifically designed to grip cable coils securely.

- Flexibility: Stacking patterns, layer counts, and pallet types can be programmed via the robot controller or line HMI.

- Integration: Often works in conjunction with automatic pallet dispensers and potentially stretch wrappers for final load stabilization.

4. Key Technical Specifications Overview

| Parameter | Typical Specification / Feature | Benefit |

|---|---|---|

| Applicable Cable Dia. | Customizable (e.g., 5mm - 50mm+) | Versatility for different product lines |

| Coil Dimensions (ID/OD/W) | Fully Adjustable via HMI | Flexibility for various customer needs |

| Coiling Speed | Synchronized with Extrusion Line (e.g., up to 150m/min) | Matches production output, avoids bottlenecks |

| Strapping Material | PP Belt (Width/Thickness Variable) | Cost-effective and reliable coil securement |

| No. of Straps | 1-4 (Programmable) | Adaptable stability for different coil sizes |

| Shrink Film Type | POF / PE | Options for clarity, durability, cost |

| Shrink Tunnel Control | Precise Temperature & Airflow | Consistent, high-quality package appearance |

| Palletizing Robot | 4/6-Axis Industrial Robot (Payload/Reach varies) | High speed, accuracy, and flexibility |

| Stacking Patterns | Programmable | Optimized pallet density and stability |

| Control System | PLC with Touchscreen HMI | Centralized control, easy operation & config |

| Integration | Direct link to Extrusion Line, MES/ERP possible | Seamless workflow, data potential |

(Note: Specific values are illustrative and depend heavily on the customized configuration.)

5. Design Philosophy: Modularity and Customization

A key strength of systems like the one offered by Fhopepack lies in their modular design. This allows for:

- Tailored Solutions: Each module (coiler, strapper, wrapper, palletizer) can be selected and configured based on the specific requirements of the cable type, production volume, available space, and budget.

- Scalability: The line can potentially be expanded or modified in the future if production needs change.

- Optimized Footprint: Layouts are designed to make efficient use of factory floor space.

The entire line is engineered for robustness and reliability in demanding industrial environments, utilizing high-quality components and advanced control systems (typically PLC-based with user-friendly HMIs).

6. Seamless Integration & Workflow

The "online" aspect signifies direct integration with the cable production process, typically connecting immediately after the extrusion line's cooling trough and caterpillar/puller unit. This ensures a continuous flow:

- Cable exits extruder and cooling system.

- Length is measured, and the cable is fed directly into the automatic coiler.

- Once the target length is reached, the cable is cut, and the full coil is ejected onto the conveyor.

- The coil moves to the strapping station for automatic tying.

- The strapped coil proceeds to the shrink wrapping station (sealing and shrinking).

- The final packaged coil is picked by the robot and placed onto a pallet according to the programmed pattern.

- Full pallets are automatically discharged (potentially to a stretch wrapper or holding area).

7. Operational Benefits & ROI

Implementing a fully automated cable packing line delivers significant advantages:

- Increased Throughput: Dramatically faster than manual methods, keeping pace with high-speed production.

- Reduced Labor Costs: Frees up operators for more value-added tasks, reducing direct labor expenditure.

- Improved Consistency & Quality: Ensures every coil is wound, strapped, wrapped, and stacked uniformly, enhancing product presentation and protection.

- Enhanced Workplace Safety: Eliminates manual lifting and handling of heavy coils, reducing injury risks.

- Optimized Material Usage: Precise application of strap and film minimizes waste.

- Data & Traceability: Advanced systems can offer data logging for production monitoring and quality control.

The Return on Investment (ROI) is typically realized through labor savings, increased efficiency, reduced waste, and improved product quality.

8. From the Operator's Perspective: User Experience Matters

Beyond the technical specifications, the user experience is critical. Modern automated lines emphasize:

- Intuitive HMI: Touchscreen interfaces allow for easy setup, parameter adjustments (coil size, strap number, shrink temperature, stacking pattern), real-time monitoring, and diagnostics.

- Quick Changeovers: Designed for relatively fast adjustments when switching between different cable types or coil sizes.

- Reliability & Maintenance: Built with durable components and designed for accessibility to minimize downtime and simplify routine maintenance. Alarms and diagnostic screens help pinpoint issues quickly.

automatic cable coiling2 9. Choosing the Right Automation Partner

Implementing such a sophisticated system requires a partner with deep expertise in both cable handling and packaging automation. Fhope Packing Team demonstrates this capability, offering customized solutions tailored to specific production environments and cable characteristics. Key considerations when selecting a provider include:

- Proven experience in the wire and cable industry.

- Ability to customize the system to specific needs.

- Robust machine design and quality components.

- Comprehensive support, including installation, training, and after-sales service.

Conclusion: Automate to Elevate

The transition to fully automated online cable packing represents a significant step forward for manufacturers seeking to optimize their end-of-line processes. By integrating coiling, strapping, shrink wrapping, and palletizing into a single, efficient system, businesses can achieve substantial improvements in speed, consistency, cost-efficiency, and safety. This technology not only addresses current production challenges but also positions companies for future growth in a competitive global market.

For customized automated cable packing solutions tailored to your specific needs, connect with the experts:

Website: www.fhopepack.com

Email: coiler@fhopepack.com