Enhancing Packaging Efficiency: The Role of Automated Belly Banding Machines in Book Bundling and Distribution

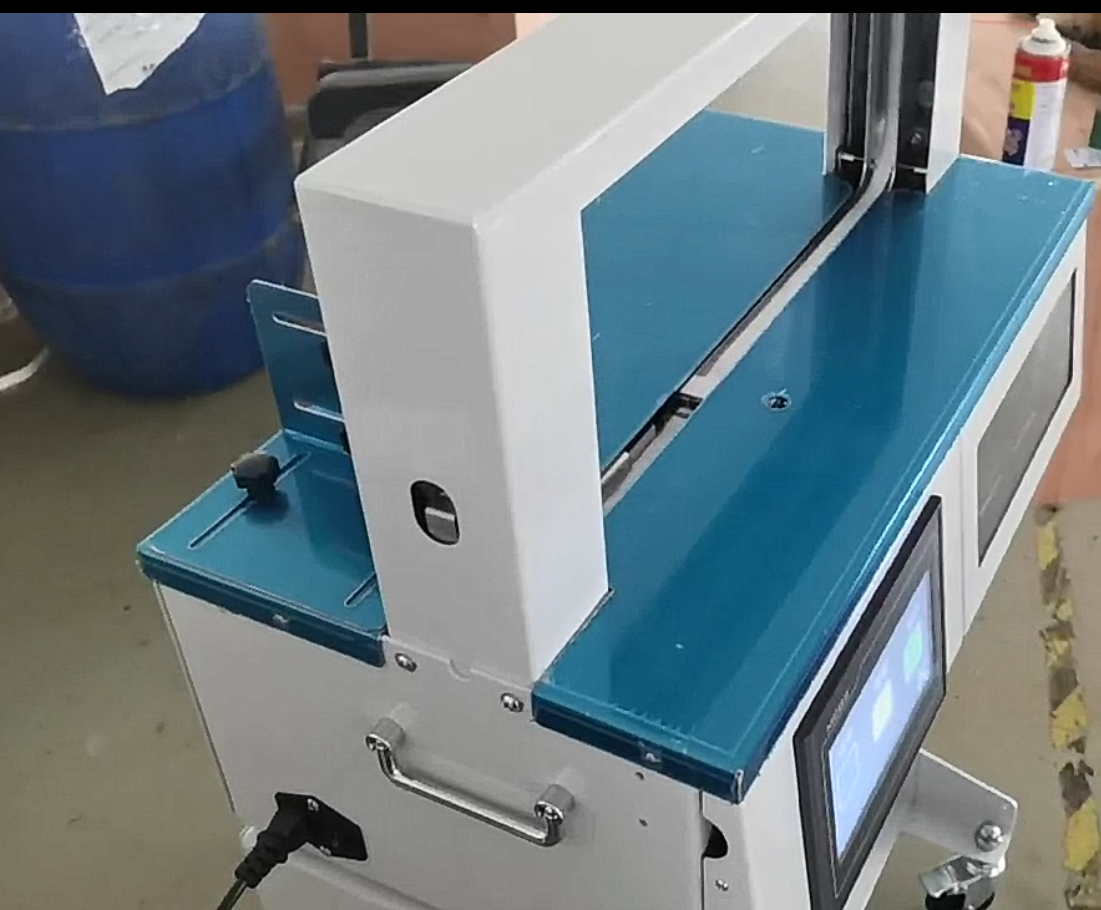

In today's competitive distribution landscape, optimizing packaging processes for speed, efficiency, and product presentation is paramount. For industries handling items like books, notebooks, brochures, or similar flat-profile products, secure and aesthetically pleasing bundling is a key operational step. The automated belly banding strap machine emerges as a critical technology, addressing these needs by applying a wide strap, or "belly band," around items. This method not only secures bundles for handling and shipping but also offers valuable space for branding and informational content, enhancing the unboxing experience.

Core Operational Principles and Technological Advancements

Modern belly banding machines integrate sophisticated mechanisms, often drawing from innovations highlighted in packaging technology patents and research, to ensure consistent and reliable operation. The typical process involves:

- Item Infeed: Products, such as stacks of books or notebooks, are manually placed or automatically fed via conveyor onto the machine's designated banding area. Sensors often detect product presence and position.

- Band Feeding & Measurement: A roll of banding material (paper or film) is automatically fed, measured precisely according to the bundle's dimensions, and cut to the required length. Advanced systems utilize servo motors for precise control over material feed.

- Band Application & Tensioning: The cut band is expertly wrapped around the bundle. Crucially, sophisticated tension control systems—a frequent focus of technological refinement—apply the optimal force to secure the items without causing damage, such as indentations on softcover books. This adjustable tension is key for handling a diverse range of product sensitivities.

- Sealing: The band ends are typically joined using heat sealing or ultrasonic welding, creating a strong, tamper-evident closure. Ultrasonic sealing, noted in recent packaging studies for its low energy consumption and ability to securely bond coated materials, is increasingly common.

- Bundle Ejection: The completed bundle is ejected from the machine, often onto an outbound conveyor, ready for the next stage in the packaging or distribution line.

Material Considerations: Balancing Performance and Sustainability

The choice of banding material significantly impacts both the functional and environmental aspects of the packaging:

- Paper Bands: Offer excellent printability for branding and variable data (like barcodes or promotional codes). Often preferred for their perceived eco-friendliness and recyclability. Research indicates growing consumer preference for paper-based packaging solutions.

- Plastic Film Bands (e.g., PP, PE): Provide higher tensile strength and moisture resistance compared to paper. Transparent options allow product visibility. Innovations continue in developing thinner, stronger, and more recyclable film options.

Material selection often depends on the product's weight, required strength, desired aesthetics, and corporate sustainability goals.

Key Performance Indicators and Specifications

When evaluating belly banding solutions, distributors and operations managers typically consider the following parameters:

- Speed: Cycles per minute (CPM), often ranging from 15 to 30+ depending on bundle size and machine configuration.

- Bundle Size Capacity: Minimum and maximum Length x Width x Height dimensions the machine can accommodate.

- Band Material Compatibility: Types of materials (paper/film), widths (e.g., 20mm - 100mm), and thicknesses supported.

- Tension Range: Adjustable tension settings (measured in Newtons or lbs) to suit different products.

- Sealing Technology: Heat seal, ultrasonic.

- Control System: Typically PLC-controlled with an HMI (Human-Machine Interface) for easy setup and operation.

Applications Across Industries

The versatility of belly banding machines makes them valuable assets in various sectors:

- Publishing and Print Finishing: Bundling books, magazines, notebooks, and marketing collateral. Gentle handling prevents damage to covers and pages, while the band offers prime branding real estate.

- E-commerce Fulfillment: Grouping multiple items within an order, reducing the need for excessive void fill and improving presentation upon unboxing. Industry reports highlight banding as a method to enhance efficiency in pick-and-pack operations.

- Retail and CPG: Creating multi-packs, promotional bundles (e.g., "Buy One Get One Free"), and shelf-ready units. Bands can carry essential product information and barcodes.

- Pharmaceuticals & Nutraceuticals: Securely bundling boxes or cartons, sometimes incorporating tamper-evident features or serialization data printed directly onto the band.

Integration and Automation Potential

For high-volume operations, belly banding machines are frequently integrated into fully automated packaging lines. They can receive products directly from upstream equipment (like printers or collators) and feed bundled items to downstream systems (such as case packers or palletizers) via conveyor belts. Network connectivity allows for centralized control and performance monitoring, aligning with Industry 4.0 principles often discussed in manufacturing and distribution journals.

Conclusion: A Strategic Packaging Solution

Automated belly banding strap machines represent more than just a method for bundling; they are a strategic tool for enhancing operational efficiency, improving product presentation, reducing material consumption compared to full overwrapping, and adding value through branding opportunities. By leveraging precise control systems, versatile material handling, and integration capabilities, these machines provide a tangible return on investment for distributors and manufacturers focused on optimizing their packaging and fulfillment processes. As noted in publications like Industrial Distribution, investments in such automation are key to maintaining competitiveness and meeting evolving market demands.