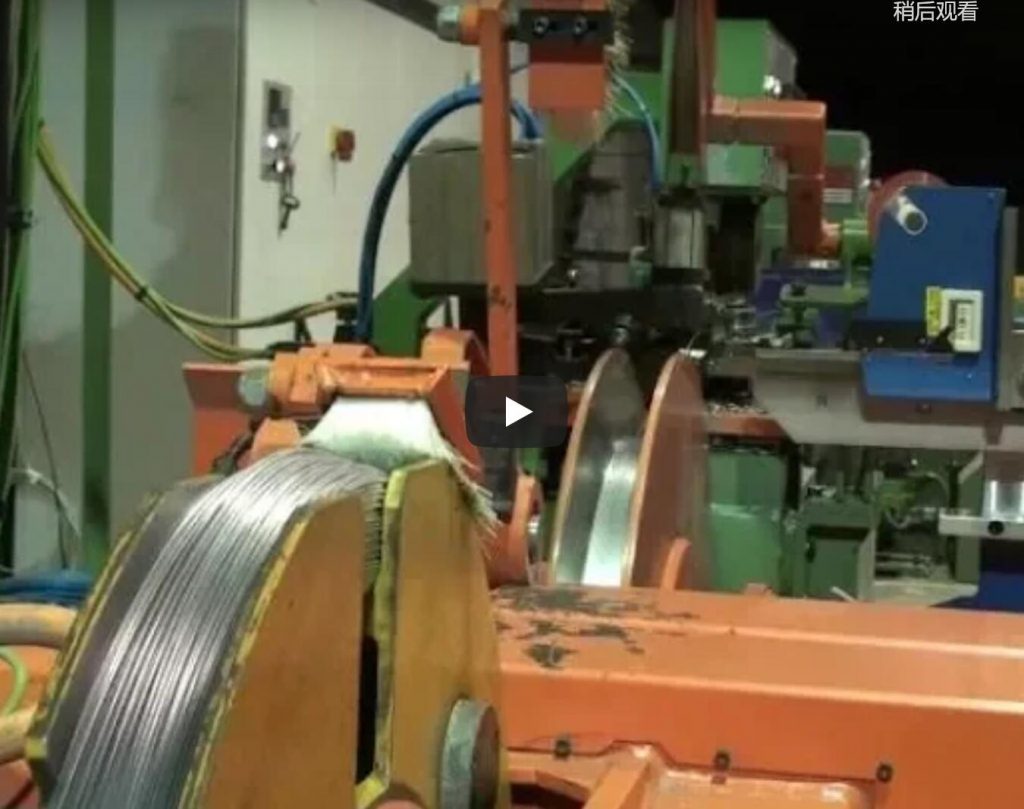

The automation of steel wire processing represents a significant leap forward in manufacturing efficiency and consistency. This integrated system showcases a complete solution, encompassing automatic steel wire coiling, strapping, and rewinding, designed to meet the demanding requirements of modern industrial production. The video above provides a visual demonstration of this sophisticated machinery in operation.

1. System Overview: Integrated Wire Handling Automation

This automated line streamlines the entire process from bulk wire supply to finished, securely strapped coils. It typically integrates several key stages into a seamless workflow:

- Wire Payoff: Controlled unwinding of the master wire coil.

- Accumulation (Optional): Buffering wire to ensure continuous operation during coil changes or brief downstream stops.

- Coiling: Precisely winding the steel wire into specified coil dimensions.

- Strapping: Automatically applying and securing straps around the finished coil.

- Rewinding/Bundle Making (Optional): Further processing or grouping of coils as per application needs.

This integration minimizes manual handling, reduces cycle times, and ensures consistent quality output.

2. Core Components and Functionality

Understanding the function of each component highlights the system's capabilities:

- Payoff Machine: Often equipped with dancers or tension control systems, the payoff unit ensures smooth wire feeding into the coiling machine without introducing unnecessary tension or slack, crucial for consistent coil formation. It handles the initial bulk wire spool.

- Wire Accumulator: In high-speed lines or applications requiring uninterrupted production, an accumulator acts as a buffer, storing a length of wire. This allows the coiling machine to continue running while the payoff performs a spool changeover.

- Automatic Coiling Head: This is the heart of the system. It utilizes precision guides and a rotating mechanism to form the wire into coils of predetermined inner diameter (ID), outer diameter (OD), and traverse width. Modern systems often feature servo controls for high accuracy and repeatability.

- Automatic Strapping Unit: Once the coil reaches the target size/weight, it's transferred to the strapping station. This unit automatically applies, tensions, seals (usually via heat or friction weld for PET straps, or crimping for steel straps), and cuts the strap material (commonly PET or steel). Multiple straps can often be applied at programmed positions for enhanced coil security.

- Control System (PLC & HMI): A Programmable Logic Controller (PLC) orchestrates the entire sequence, synchronizing the actions of each component. A Human-Machine Interface (HMI), typically a touchscreen panel, allows operators to set parameters (coil dimensions, wire specs, strap positions), monitor the process, and perform diagnostics.

3. Key Technical Specifications

While specific parameters vary by model and manufacturer, typical specifications for such a line include:

- Wire Diameter Range: e.g., 1.0 mm - 6.0 mm

- Coil Inner Diameter (ID): e.g., 300 mm - 600 mm

- Coil Outer Diameter (OD): e.g., 500 mm - 1200 mm

- Coil Width: e.g., 50 mm - 500 mm

- Maximum Coil Weight: e.g., 100 kg - 2000 kg

- Line Speed: Variable, e.g., up to 120 m/min (depending on wire diameter and coil specs)

- Strapping Material: PET or Steel strap

- Number of Straps: Programmable, typically 3 or 4

- Control: PLC system with HMI Touchscreen

- Power Supply: 380V/50Hz/3Ph (or customized)

(Note: These are representative values. Actual specifications depend on the specific machine configuration.)

4. Design, Structure, and Build Quality

Adhering to industrial standards, these machines feature robust construction for durability and operational stability:

- Frame: Heavy-duty welded steel frame provides rigidity and vibration damping.

- Components: Use of high-quality bearings, motors, sensors, and pneumatic/hydraulic elements ensures reliability.

- Modularity: Often designed with a degree of modularity, allowing for easier integration, potential future upgrades, or customization.

- Safety: Comprehensive safety features are essential, including physical guarding, safety interlocks on access doors, emergency stop buttons readily accessible, and light curtains in hazardous areas, often complying with CE or equivalent safety standards.

- Maintenance: Design considerations typically include accessibility for routine maintenance and component replacement.

5. Operational Advantages and Efficiency Gains

Implementing an automated steel wire coiling and strapping line offers significant benefits:

- Reduced Labor Costs: Minimizes the need for manual coil handling, strapping, and transport.

- Increased Throughput: Continuous, automated operation significantly increases production output compared to manual or semi-automatic methods.

- Improved Coil Quality: Precise winding and consistent strap tension lead to uniform, stable, and aesthetically pleasing coils.

- Enhanced Safety: Reduces operator exposure to moving machinery and heavy coils.

- Material Savings: Optimized strap usage and reduced product damage during handling.

- Process Consistency: Eliminates variability inherent in manual operations, ensuring every coil meets specifications.

6. User Experience and Application Insights

From an operational perspective, modern automated lines focus on user-friendliness and adaptability:

- Ease of Operation: Intuitive HMI allows for relatively quick setup of coil parameters and monitoring of production status. Recipe storage can enable fast changeovers between different product specifications.

- Integration: These lines are designed to be integrated into larger wire drawing, annealing, or coating production facilities, receiving wire directly from upstream processes.

- Diagnostics: Advanced control systems often include self-diagnostic capabilities, aiding in troubleshooting and reducing downtime.

- Typical Applications: Widely used in industries producing or consuming large quantities of steel wire, such as construction (rebar tie wire, mesh wire), manufacturing (spring wire, fencing wire), automotive, and general engineering.

7. Conclusion: Investing in Automated Wire Packaging

The automatic steel wire coiling and strapping machine, often integrated with payoff and potentially rewinding functions, represents a crucial automation solution for the steel wire industry. By combining precision engineering, robust construction, and intelligent control systems, this technology delivers substantial improvements in efficiency, consistency, safety, and overall productivity. For manufacturers seeking to optimize their wire handling and packaging processes, investing in such an automated system offers a clear path towards enhanced competitiveness and operational excellence.