Revolutionizing Steel Wire Packaging: A Deep Dive into Automated Coil Wrapping Lines

The global steel industry demands relentless efficiency and precision, particularly in downstream processes like packaging. Handling heavy, cumbersome steel wire coils presents unique challenges: ensuring product integrity, optimizing logistical flow, and maintaining workforce safety. This article delves into the advanced automated solutions transforming steel wire coil packaging, focusing on the design, technology, and operational benefits showcased in the accompanying video.

1. The Challenge: Overcoming Traditional Packaging Hurdles

Manual or semi-automated steel wire coil packaging methods often grapple with several inefficiencies:

- Labor Intensity: Requiring significant manpower for handling, wrapping, and stacking.

- Inconsistency: Variable wrap quality leading to potential coil damage or instability during transit.

- Safety Risks: Manual handling of heavy coils poses ergonomic and injury risks.

- Cycle Time Limitations: Slower throughput impacting overall production capacity.

- Material Waste: Inefficient use of wrapping materials like stretch film.

Addressing these points is critical for manufacturers seeking a competitive edge through operational excellence.

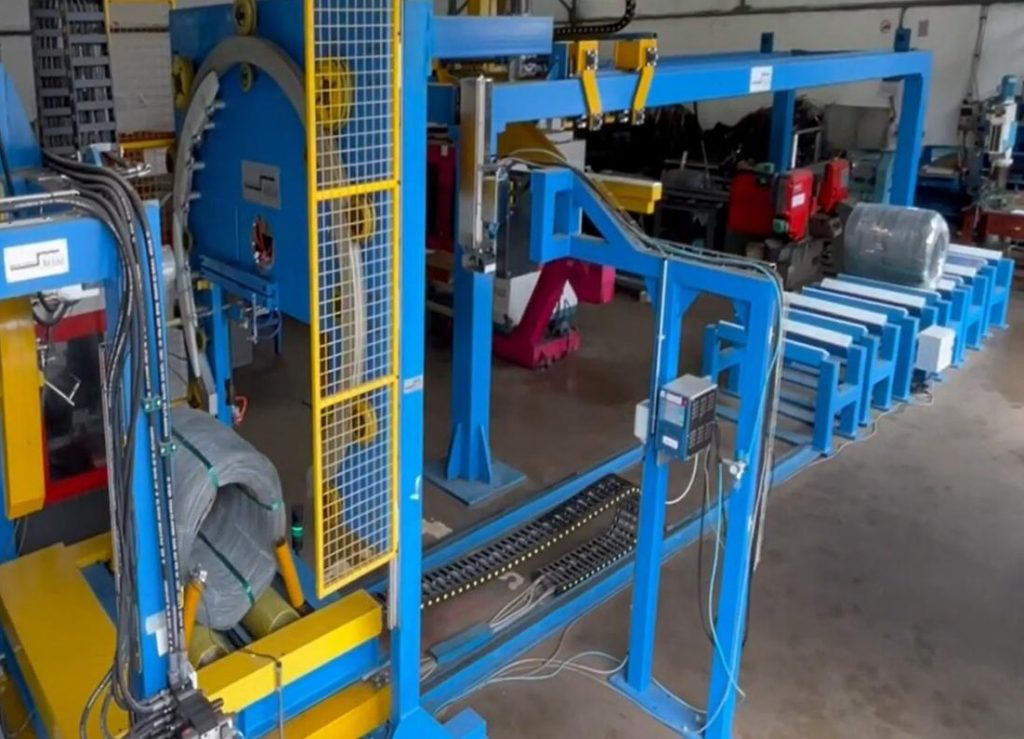

2. Unveiling the Automated Solution: A System Overview

The video highlights a state-of-the-art automated steel wire coil packing line, engineered to minimize manual intervention and maximize throughput. The core process seamlessly integrates several stages:

- Automatic Coil Loading: Coils are efficiently transferred onto conveyor systems or trolleys.

- Automatic Eye-Through Wrapping: The coil passes through the center of a rotating wrapping ring, applying stretch film securely around its circumference.

- Automatic Film Management: Systems automatically clamp, cut, and wipe the film tail.

- Automatic Labeling: Application of identification and tracking labels post-wrapping.

- Automatic Handling & Stacking: Robotic or servo-driven systems precisely pick, transport, and stack the wrapped coils for storage or dispatch.

This integrated approach exemplifies modern industrial automation tailored for the specific demands of steel wire products.

3. Deep Dive: System Design and Structural Integrity

Robustness and reliability are paramount in heavy industrial environments. These automated lines typically feature:

- Heavy-Duty Framework: Constructed from high-grade structural steel to withstand continuous operation and heavy loads.

- Modular Design: Often designed in modules (infeed, wrapping, outfeed, stacking) allowing for customization and easier integration into existing factory layouts.

- Safety Guarding: Comprehensive physical barriers, light curtains, and emergency stop systems compliant with international safety standards (e.g., ISO 13849).

- Optimized Footprint: Careful consideration of space utilization within the production facility.

The design prioritizes not just function but also durability, maintainability, and operator safety.

4. Core Components & Technical Specifications

The efficiency of the automated line hinges on the synergy of its advanced components. Let's examine key elements:

- Infeed Conveyor/Trolley System: Designed for smooth, damage-free coil transport. May utilize roller conveyors, chain conveyors, or AGV-compatible trolleys.

- Eye-Through Wrapping Unit:

- Wrapping Material: Typically utilizes LLDPE stretch film (specifications vary based on coil weight and required protection, e.g., 23-35 micron thickness, specific pre-stretch ratios like 250-300%).

- Rotation Speed: High-speed wrapping rings achieve rapid cycle times.

- Overlap Control: Precisely controlled via the PLC for consistent and secure wrapping.

- Tension Control: Electronic systems ensure optimal film tension throughout the wrap cycle.

- Automatic Film Cut & Clamp System: Pneumatically or electrically actuated mechanisms for reliable film management at cycle end.

- Automatic Labeling System: Often integrated print-and-apply systems linked to the plant's MES/ERP for real-time data (e.g., coil ID, weight, production date).

- Servo Stacking System: Utilizes servo motors for high precision, speed, and controlled force during coil lifting, transport, and stacking, minimizing impact and ensuring stack stability.

- Control System:

- PLC (Programmable Logic Controller): The 'brain' of the system (e.g., Siemens S7 series, Allen-Bradley ControlLogix) managing all sequences, timings, and interlocks.

- HMI (Human-Machine Interface): Touchscreen panel providing operators with system status, diagnostics, parameter adjustment (e.g., wrap programs), and alarm management.

- Connectivity: Ethernet/IP, Profinet capabilities for integration with plant-level control systems.

Typical Technical Data Range (Example):

| Parameter | Typical Specification Range | Notes |

|---|---|---|

| Coil Outer Diameter | 600mm - 1500mm | Varies based on machine model |

| Coil Inner Diameter | 400mm - 800mm | Dependent on handling/wrapping mechanism |

| Coil Width | 300mm - 1000mm | Influences wrapping ring size |

| Max. Coil Weight | 500kg - 3000kg+ | Determines structural & drive requirements |

| Packing Speed | 20 - 60+ Coils/Hour | Depends on coil size & wrap parameters |

| Stretch Film Specs | Width: 76mm-150mm; Pre-stretch: Up to 300% | Material choice impacts protection & cost |

| Control System | PLC (Siemens/Allen-Bradley) + HMI | Standard industry automation platforms |

| Power Requirements | 480V/3Ph/60Hz or 380V/3Ph/50Hz | Specific to installation region |

Note: These are illustrative ranges. Specific machine capabilities depend on the manufacturer and model.

5. Operational Efficiency & User Experience: The Human Element

While highly automated, the system's design profoundly impacts the operator's role and overall efficiency:

- Single Operator Management: As highlighted, the entire line can often be overseen by just one person, primarily for monitoring, material replenishment (film rolls, labels), and handling exceptions. This drastically reduces direct labor costs.

- Reduced Physical Strain: Eliminates heavy lifting and repetitive manual wrapping tasks, significantly improving workplace ergonomics and safety.

- Consistency and Quality: Automated wrapping ensures every coil receives the same level of protection, reducing damage claims and enhancing customer satisfaction.

- Increased Throughput: Faster cycle times compared to manual methods directly translate to higher production output.

- Data Integration & Tracking: Automatic labeling and PLC data logging provide valuable traceability and production insights.

- User-Friendly Interface: Modern HMIs simplify operation, program selection, and troubleshooting.

From an operational management perspective, the experience is one of enhanced control, predictability, and significantly lower risk.

6. Integration and Customization: Fitting the Factory Flow

These automated packing lines are rarely standalone units. Successful implementation involves:

- Seamless Integration: Designing the line to connect smoothly with upstream processes (e.g., wire drawing or annealing lines) and downstream logistics (e.g., warehousing or direct truck loading).

- Data Exchange: Linking the packing line's control system with Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems for order processing, inventory management, and quality control data.

- Customization: Tailoring the line configuration, components, and software to specific coil dimensions, weights, required packing materials, and desired throughput levels. Reputable suppliers like FHOPE offer various configurations in their automated steel wire packing line range.

7. The Bottom Line: ROI and Industry Impact

Investing in an automated steel wire coil packing line delivers tangible returns:

- Reduced Labor Costs: Significant savings due to minimized manual intervention.

- Lower Material Consumption: Optimized stretch film usage through pre-stretch and precise control.

- Decreased Product Damage: Consistent, secure wrapping protects coils during handling and transit.

- Enhanced Productivity: Higher throughput boosts overall plant capacity.

- Improved Safety: Reduction in manual handling incidents.

- Competitive Advantage: Demonstrates commitment to quality, efficiency, and modern manufacturing practices.

In Conclusion:

The transition towards fully automated steel wire coil packaging represents a significant leap forward for the industry. By leveraging advanced robotics, sophisticated control systems, and intelligent design, manufacturers can overcome traditional limitations, achieving new levels of efficiency, safety, and product quality. As showcased, these systems are not just about replacing manual labor; they are about optimizing the entire packaging process, delivering substantial operational and financial benefits, and setting a new standard for excellence in steel wire handling and logistics. For further information on automation standards, resources like MHI (Material Handling Industry) offer valuable insights into best practices.