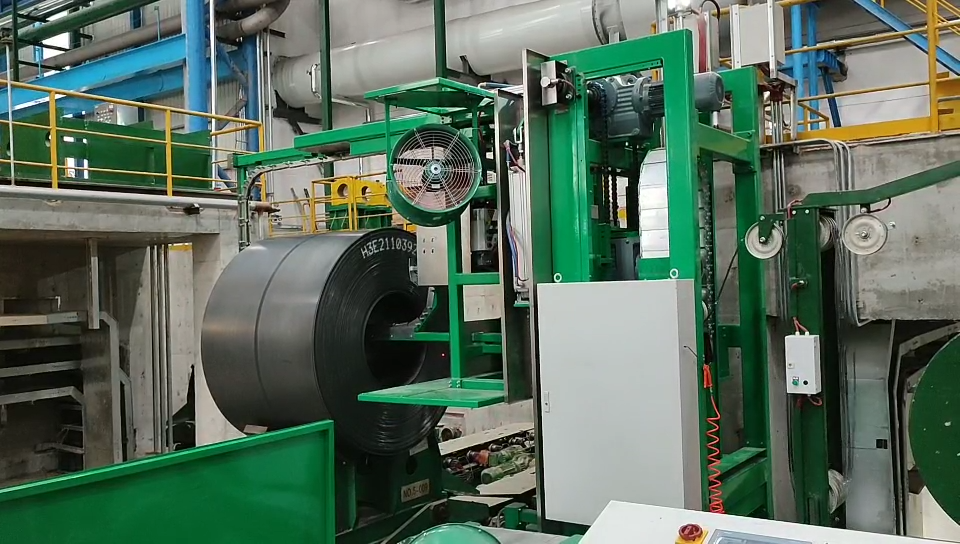

FHOPEPACK Introduces Advanced Automatic Strapping Machine for Hot Roll Steel Coils

FHOPEPACK has launched its latest innovation in steel coil handling: the Automatic Hot Roll Steel Coil Strapping Machine. Engineered to address the unique challenges of securing steel coils directly from the hot rolling mill, this system integrates advanced automation and robust design principles to enhance operational efficiency, safety, and product integrity in demanding steel manufacturing environments. Referencing advancements noted in publications like Iron & Steel Technology, the need for reliable high-temperature strapping solutions is critical for maintaining production flow and preventing costly damage or delays.

Addressing the Challenges of Hot Coil Strapping

Strapping hot-rolled steel coils presents significant technical hurdles that standard equipment often cannot overcome. Key challenges include:

- Extreme Temperatures: Coils exiting the mill can exceed 600-800°C (1112-1472°F), demanding strapping systems with components resistant to extreme heat and thermal cycling. Failure can lead to strap breakage or machine malfunction.

- Heavy and Unstable Loads: Large steel coils represent substantial weight (often up to 35 tons) and require precise, high-tension strapping to ensure stability during cooling, storage, and transport. Inconsistent tension can lead to coil telescoping or damage.

strapping machine - Harsh Operating Environment: Steel mills are characterized by dust, scale, vibrations, and potential impacts, requiring machinery built for exceptional durability and reliability. Research highlights that equipment uptime is a primary driver of profitability in mill operations.

- Safety Concerns: Manual or semi-automatic strapping in proximity to hot, heavy coils poses significant risks to personnel. Automation is crucial for meeting modern industrial safety standards (e.g., ISO 12100).

- Throughput Requirements: Modern mills operate continuously, necessitating high-speed, reliable strapping cycles to avoid bottlenecks in the production line.

The FHOPEPACK Solution: Features and Innovations

The FHOPEPACK Hot Roll Steel Coil Strapping Machine incorporates technologies designed specifically to overcome these challenges, drawing inspiration from patented strapping head mechanisms and material science advancements.

High-Temperature Resilience

Engineered with specialized heat shields and high-temperature resistant materials for critical components, including the strapping head and track system. This design ensures reliable strap feeding, tensioning, and sealing even when operating close to hot coils, a feature often highlighted in technical papers discussing mill automation.

Robust Strapping Head Technology

Features a high-performance strapping head designed for consistency and durability. The system utilizes either steel or high-temperature resistant PET strapping, applying precise and adjustable tension (up to approx. 15,000 N) before executing a secure seal (e.g., notch or seal-less joint for steel, friction-weld for PET). This precision minimizes strap failure and coil damage, aligning with quality control requirements in steel production.

Advanced Automation and Seamless Integration

Utilizing PLC controls (Siemens or Allen-Bradley options available), the machine operates fully automatically. It can be integrated seamlessly into existing coil conveying lines and plant control systems (MES/Level 2), ensuring coordinated movement and strapping operations without manual intervention. This level of automation is consistent with Industry 4.0 trends discussed in manufacturing journals.

Enhanced Safety Features

The system is designed with safety as a priority, incorporating physical guarding, safety interlocks, and sensors to protect personnel. Remote operation and monitoring capabilities further reduce human exposure to the hazardous coil handling area, contributing to compliance with stringent occupational safety regulations.

Durability for Mill Environments

Constructed with a heavy-duty frame and components selected for longevity in harsh conditions. Design considerations include protection against scale ingress and ease of access for routine maintenance, minimizing downtime and total cost of ownership – key metrics tracked by plant managers.

Technical Specifications Overview

- Coil Temperature Handling: Up to 800°C (1472°F) capability

- Applicable Coil OD: 900mm – 2100mm (approx.)

- Applicable Coil Width: 500mm – 2000mm (approx.)

- Maximum Coil Weight: Up to 35 Tons (approx.)

- Strapping Material: Steel Strapping or High-Temperature PET Strapping

- Strap Dimensions (Typical):

- Width: 19mm / 25mm / 32mm

- Thickness: 0.8mm – 1.2mm

- Strapping Head Type: High-reliability sealing head (specific type based on strap material)

- Tensioning Force: Electronically adjustable, up to 15,000 N (approx.)

- Average Cycle Time: 30 – 45 seconds per strap (dependent on coil size and strapping configuration)

- Control System: Siemens S7 series or Allen-Bradley ControlLogix PLC

Significant Operational Benefits

Implementing the FHOPEPACK strapping machine delivers tangible advantages for steel producers:

- Increased Mill Throughput: Fast, automated strapping cycles prevent delays in coil logistics.

- Enhanced Product Protection: Consistent, high-integrity strapping secures coils effectively, reducing damage during handling and transit.

- Improved Workplace Safety: Eliminates manual strapping in high-risk zones near hot coils.

- Reduced Operating Costs: Automation lowers labor requirements, and robust design minimizes maintenance and strap wastage.

- Process Reliability: Ensures dependable strapping performance shift after shift, contributing to overall production stability.

"This machine addresses critical bottlenecks in hot mill logistics. Our focus on high-temperature component reliability and precise strap placement directly translates to improved coil integrity and safer handling downstream," states Mr. Liu, Product Manager at FHOPEPACK. "It's engineered not just to strap, but to optimize a crucial step in the steel production value chain."

Advancing Steel Coil Packaging

FHOPEPACK's Automatic Hot Roll Steel Coil Strapping Machine represents a significant advancement in steel coil packaging technology, offering a robust, efficient, and safe solution tailored to the demanding environment of modern steel mills. It reflects ongoing industry efforts, documented in trade publications and patent literature, to automate and improve challenging industrial processes.

To learn how this technology can optimize your specific hot mill operations, contact FHOPEPACK for detailed specifications, case studies, or to arrange a consultation with their engineering team.