Advancing Slit Coil Logistics: Integrating Turntables into Automated Packing Lines

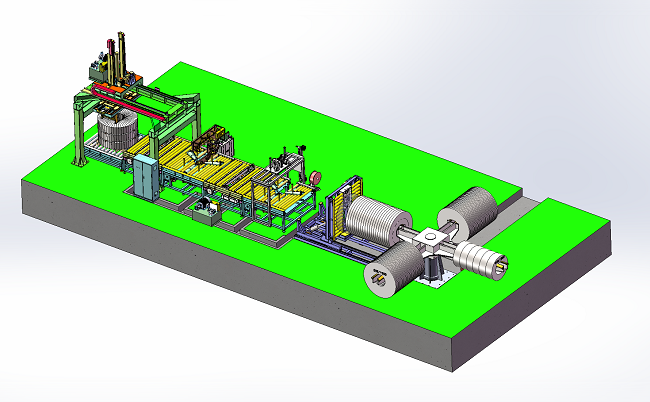

The efficient handling and packaging of slit coils represent a critical node in the metal processing supply chain. Traditional manual methods often introduce bottlenecks, potential for material damage, and ergonomic risks for personnel. Addressing these challenges requires sophisticated automation, such as the advanced automatic slitting coil packaging line featuring an integrated turntable, designed to streamline operations from slitting line exit to final dispatch.

The Operational Imperative for Automated Coil Packaging

Handling slit coils, often with sharp edges and substantial weight, presents inherent difficulties. Manual or semi-automated processes can struggle with:

- Product Damage: Improper handling can lead to edge damage, telescoping, or surface scratches, impacting material yield and quality.

- Process Inefficiencies: Manual strapping, weighing, and labeling are time-consuming and labour-intensive, limiting overall throughput.

- Safety Concerns: Manual lifting and manipulation of heavy coils pose significant ergonomic hazards.

- Traceability Gaps: Accurate tracking of individual slit coils through the packaging process is vital for inventory management and quality control, a task prone to error in manual systems.

Automated systems, incorporating technologies often refined through iterative design and patent advancements (e.g., advancements in gripper designs, rotational control systems, and sensor integration), directly mitigate these issues.

Core Technologies of the Turntable-Equipped Packing Line

This state-of-the-art system integrates several key functions into a cohesive workflow, enhancing precision and speed:

The Turntable: A Hub for Efficiency

The central turntable mechanism is pivotal. Its primary function is to receive slit coils (often eye-to-the-sky) and precisely rotate them for subsequent automated processes. This capability is crucial for:

- Orientation for Strapping: Allows for accurate radial and/or circumferential strapping without manual repositioning. Research indicates that consistent strap placement and tension are key to maintaining coil integrity during transport (Source: Industry studies on coil securement).

- Positioning for Weighing & Labeling: Ensures coils are correctly placed on integrated weigh scales and presented optimally for automated label application.

- Streamlined Flow: Eliminates interruptions and manual handling between process steps, creating a continuous, efficient flow.

Integrated Process Modules

The system seamlessly combines multiple operations performed in real-time:

- Automated Strapping: Applies steel or PET strapping according to pre-programmed parameters, ensuring secure and stable packaging suitable for transport and storage. Variations in strapping head technology allow for adaptation to different coil sizes and materials.

- Precision Weighing: Integrated load cells capture accurate weight data for each coil, essential for shipping documentation, inventory control, and yield calculations.

- Real-Time Printing & Labeling: Automatically generates and applies labels containing critical data (e.g., weight, dimensions, material grade, customer ID, barcodes/QR codes) linked directly to production orders.

- Automated Stacking: Carefully stacks packaged coils onto pallets or skids according to pre-defined patterns, optimizing storage density and stability.

The Power of Data: ERP System Integration

A defining feature of modern automated packaging lines is their ability to connect seamlessly with plant-wide Enterprise Resource Planning (ERP) systems. This integration transforms the packaging line from a standalone unit into an intelligent node within the larger manufacturing ecosystem. Benefits include:

- Real-Time Data Synchronization: Packaging completion data, weights, and identification information are instantly updated in the ERP system, providing accurate, real-time visibility into finished goods inventory.

- Enhanced Traceability: Creates a digital thread connecting each slit coil back to its master coil and production parameters, crucial for quality assurance and compliance.

- Optimized Logistics: Accurate, real-time data facilitates efficient warehouse management, dispatch planning, and coordination with logistics providers.

- Improved Production Planning: Feedback from the packaging line on throughput and status can inform upstream production scheduling.

Design Considerations and Versatility

The design of these automatic lines prioritizes robustness and adaptability:

- Material Compatibility: Engineered to handle a wide range of materials common in fabrication and service centers, including steel (carbon, stainless), aluminum alloys, copper, brass, and other non-ferrous metals.

- Coil Specification Range: Configurable to accommodate varying coil inner diameters (ID), outer diameters (OD), widths, and weights, often incorporating adjustable guides, sensors, and strapping parameters.

- Modular Design: Often built with modularity in mind, allowing for customization based on specific plant layouts and process requirements.

Conclusion: Driving Efficiency in Metal Coil Processing

The automatic slitting coil packaging line with an integrated turntable represents a significant advancement in metal processing logistics. By automating critical tasks like strapping, weighing, labeling, and stacking, and integrating seamlessly with ERP systems, this technology delivers substantial improvements in efficiency, accuracy, safety, and traceability. For metal service centers and fabricators seeking to optimize their coil handling operations, reduce costs, and enhance product quality, such automated solutions offer a compelling value proposition, aligning with the operational excellence goals highlighted in industry publications like The Fabricator.

For more information on tailoring automated coil packaging solutions to your specific operational needs, please contact us via email info@fhopepack.com.