Streamlining Operations: An In-Depth Look at the Automatic Pipe and Tube Bagging Machine

In modern industrial environments, particularly in the manufacturing and distribution of pipes, tubes, and profiles, efficiency and product protection are paramount. Manual bagging processes are often time-consuming, labor-intensive, and can lead to inconsistencies in packaging quality. The automatic pipe and tube bagging machine presents a robust solution, automating the packaging process to enhance throughput, reduce operational costs, and ensure consistent product protection. This article provides a technical overview of its functionality, design, specifications, and benefits, aligning with the practical insights valued by industry professionals.

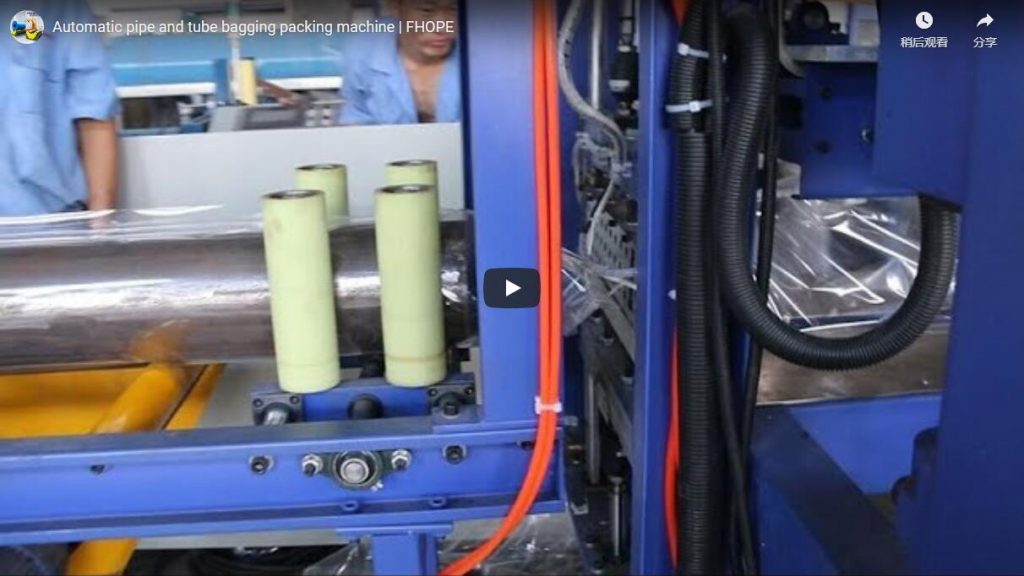

1. Core Functionality and Operational Workflow

The primary function of this automated system is to individually enclose pipes or tubes within a protective plastic bag. The operational sequence is typically as follows:

- Infeed: Pipes or tubes are fed onto the machine's infeed conveyor system, either manually or integrated from an upstream process (e.g., extrusion line, cutting station). Sensors detect the presence and position of the incoming product.

- Bag Formation and Insertion: A roll of flat packaging film (typically PE - Polyethylene) is dispensed. The machine forms a bag around the pipe as it advances or inserts the pipe into a pre-formed section of the continuous film tube.

- Sealing: Once the pipe is correctly positioned within the film, a sealing mechanism (often using heat) creates a secure transverse seal at both ends of the pipe, encapsulating it.

- Cutting: Simultaneously or immediately after sealing, an automated cutting mechanism separates the bagged pipe from the continuous film roll.

- Outfeed: The individually bagged pipe is then transferred onto an outfeed conveyor.

- Discharge/Stacking: The system pushes the finished, bagged pipe off the outfeed conveyor, often preparing it for bundling, stacking, or further handling downstream.

This seamless, automated workflow minimizes manual intervention, ensuring speed and consistency.

2. Key Design Features and Structural Components

A typical automatic pipe bagging machine incorporates several key engineering elements:

- Heavy-Duty Frame: Constructed from robust steel profiles to ensure stability, durability, and vibration dampening during operation in demanding industrial settings.

- Conveyor Systems:

- Infeed Conveyor: Designed to gently handle pipes/tubes, often featuring adjustable guides and non-marking rollers or belts to prevent surface damage. Length and speed are typically customizable.

- Outfeed Conveyor: Transports the bagged product away from the sealing/cutting station. May include sensors for downstream process signaling.

- Film Dispensing Unit: Securely holds the film roll, with tension control mechanisms to ensure smooth and consistent film feeding. May include automatic centering features.

- Sealing and Cutting Head: The core of the bagging operation. Utilizes thermal sealing bars (impulse or constant heat) for reliable seals and a precision cutting blade (often pneumatic or servo-driven) for clean separation. Temperature and dwell time are typically adjustable for different film types and thicknesses.

- Pneumatic Pusher/Ejector: Actuates to discharge the finished product from the outfeed conveyor, enabling collection or stacking.

- Control System: Usually managed by a Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) touchscreen. This allows operators to set parameters (pipe length, sealing time, etc.), monitor the process, and troubleshoot diagnostics.

- Safety Features: Includes emergency stop buttons, safety guards around moving parts, and interlocks to comply with industrial safety standards.

3. Technical Specifications Overview

While specific parameters vary significantly based on model and customization, here's a typical range of technical specifications for consideration:

| Parameter | Typical Range / Specification | Notes |

|---|---|---|

| Applicable Pipe/Tube Diameter | 10 mm – 250 mm (0.4" – 10") | Varies widely based on machine model |

| Applicable Pipe/Tube Length | 1 m – 12 m (3.3 ft – 40 ft) | Customizable; longer lengths may require support |

| Packing Speed | 3 – 10 pieces/minute | Dependent on pipe dimensions and film type |

| Applicable Film Material | PE (Polyethylene), POF (Polyolefin) | Consult manufacturer for specific compatibility |

| Film Thickness | 30 – 100 microns (µm) | Dependent on required protection level |

| Sealing Type | Heat Seal (Impulse or Constant) | |

| Control System | PLC + HMI Touchscreen | Standard for modern industrial automation |

| Power Supply | 380V/50Hz/3Phase (or regional std.) | Specify requirements upon ordering |

| Compressed Air | 0.5 – 0.7 MPa | Required for pneumatic actuators |

| Machine Dimensions (LxWxH) | Highly variable; e.g., 8m x 1.5m x 1.8m | Requires significant floor space |

Note: These are representative figures. Always refer to the manufacturer's specific data sheet for the exact model.

4. Material Handling and Integration Capabilities

Effective integration into existing production lines is crucial. These machines are designed with this in mind:

- Infeed/Outfeed Synchronization: Can often be electronically linked with upstream equipment (like extruders or saws) and downstream systems (like bundlers or stackers) using sensors and control signals for seamless material flow.

- Conveyor Customization: Conveyor heights, lengths, and types (rollers, belts) can usually be adapted to match existing line configurations.

- Handling Diverse Profiles: While optimized for round pipes/tubes, some models can be adapted to handle square, rectangular, or irregular profiles with appropriate guiding adjustments.

5. Advantages and ROI Considerations

Investing in an automatic pipe bagging machine offers tangible benefits:

- Increased Throughput: Significantly faster than manual bagging, boosting overall production output.

- Reduced Labor Costs: Frees up personnel previously assigned to manual packing tasks for more value-added activities.

- Enhanced Product Protection: Provides a consistent, sealed barrier against dust, dirt, moisture, and superficial scratches during storage and transit.

- Improved Packaging Consistency: Ensures every pipe is bagged uniformly, enhancing product presentation and perceived quality.

- Operational Efficiency: Streamlines the end-of-line process, reducing bottlenecks.

- Potential Material Savings: Optimized film usage compared to potentially wasteful manual methods.

- Improved Workplace Safety: Reduces manual handling risks associated with large or heavy pipes.

The Return on Investment (ROI) is typically realized through labor savings, increased production speed, and reduced product damage claims.

6. Application Versatility

Automatic pipe and tube bagging machines find applications across various industries dealing with elongated products:

- Plastics Manufacturing: PVC, CPVC, PEX, HDPE pipes and conduits.

- Metal Fabrication: Steel tubes, aluminum profiles, copper pipes.

- Construction Materials: Various types of conduits, profiles, and structural elements.

- Window and Door Manufacturing: Extruded profiles.

- Automotive Suppliers: Exhaust pipes, structural tubing.

7. User Experience and Maintenance

From an operational standpoint:

- Ease of Operation: Modern HMI interfaces provide intuitive controls for parameter adjustments, recipe management (for different pipe sizes), and status monitoring.

- Film Roll Changes: Designed for relatively quick and straightforward film roll replacement to minimize downtime.

- Maintenance: Routine maintenance typically involves cleaning sealing bars, checking blade sharpness, inspecting pneumatic components, lubricating moving parts, and verifying sensor functionality. Access points are usually designed for easy maintenance.

- Safety Compliance: Built-in safety features protect operators during normal operation and maintenance routines.

Conclusion

The automatic pipe and tube bagging machine is a specialized yet vital piece of equipment for industries requiring efficient and protective packaging of long products. By automating the infeed, bagging, sealing, cutting, and outfeed processes, it delivers significant improvements in speed, consistency, labor efficiency, and product protection compared to manual methods. Its robust design, integration capabilities, and user-friendly controls make it a valuable asset for streamlining end-of-line packaging operations and ensuring products reach their destination in optimal condition. For facilities looking to enhance productivity and packaging quality, evaluating the technical specifications and ROI potential of such automated systems is a critical step forward.

For further information or specific technical consultation:

Website: www.fhopepack.com

Email: info@fhopepack.com

Phone: +86 15021705930