In modern cable and wire manufacturing, efficiency, precision, and streamlined packaging are paramount. Manual processes for coiling, strapping, and packing cables are often labor-intensive, prone to inconsistencies, and can create bottlenecks in production. The Automatic Cable Wire Coil Winding, Strapping, and Packing Machine represents a significant technological leap forward, integrating multiple processes into a single, automated system designed to enhance throughput and ensure product integrity. This article delves into the technical aspects, operational benefits, and practical considerations of implementing such advanced machinery, aligning with the needs of today's demanding fabrication environments.

1. Understanding the Core Functionality

At its heart, this integrated system automates the entire end-of-line process for flexible cables and wires after extrusion or rewinding. The typical workflow involves:

- Precise Winding: The machine accurately measures the desired length of cable and winds it into a neat, specified coil diameter and traverse width.

- Automatic Cutting: Once the desired length is reached, the cable is cleanly cut.

- Coil Transfer: The finished coil is automatically transferred from the winding station.

- Strapping: One or more straps (typically PET or PP) are applied around the coil at pre-programmed positions to maintain its shape and prevent unraveling.

- Packing/Stacking (Optional): Depending on the configuration, the strapped coil may then be automatically placed into boxes, stacked on pallets, or wrapped in protective film.

This seamless integration minimizes manual handling, reduces cycle times, and ensures consistent output quality.

2. Key Components and Design Considerations

The reliability and performance of an automatic cable processing line hinge on the quality and design of its core components:

- Pay-off Stand (Input): While sometimes separate, integration often starts here, ensuring smooth, tension-controlled feeding of the cable.

- Measuring Unit: High-precision encoders or measuring wheels guarantee accurate cable length for each coil. Accuracy is often within ±0.1% to ±0.5%.

- Winding Head/Coiler: This unit forms the coil. Designs vary, including collapsible drum winders for easy coil removal. Variable speed control (often via VFD - Variable Frequency Drive) allows adaptation to different cable types and sizes.

- Traversing System: A servo-driven or mechanically linked traversing guide ensures the cable is laid evenly across the coil width, creating stable, well-formed coils. Programmable pitch control is essential for handling diverse cable diameters.

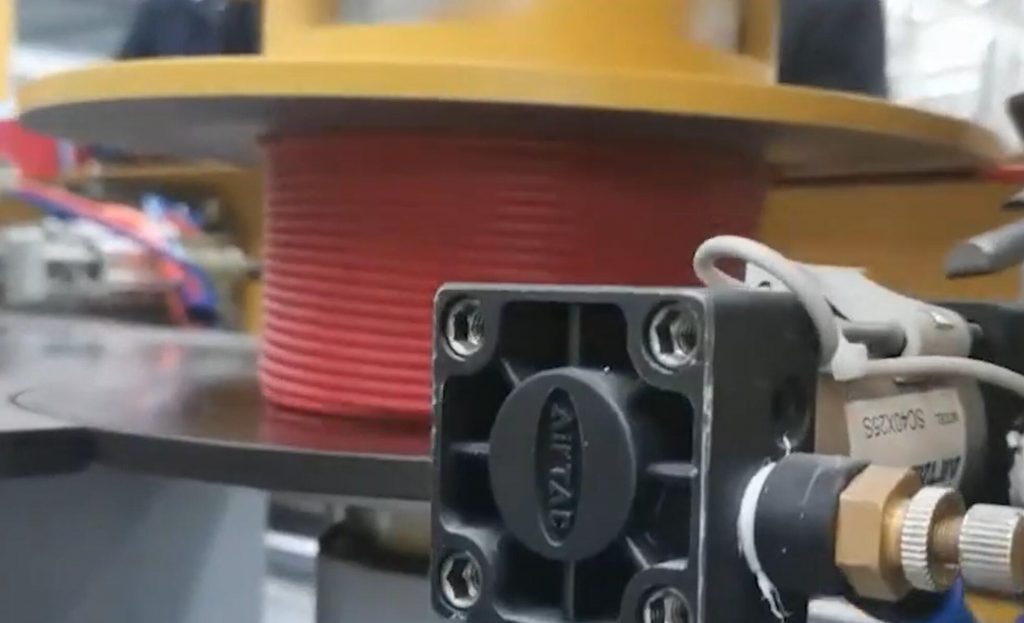

- Cutting Mechanism: Pneumatic or servo-actuated cutters provide clean, square cuts without damaging the cable conductors or insulation.

- Strapping Head: This is a critical component, often utilizing heat-sealing or friction-welding techniques for PET or PP straps. Robustness and reliability are key, as this unit performs rapid, repetitive actions. Tension control is crucial for securing the coil without damaging the cable.

- Coil Ejection/Transfer System: Mechanisms like pushers, robotic arms, or conveyors move the strapped coil to the next stage (packing or accumulation).

- Packing Station (Optional): May include automatic box erectors, coil inserters, film wrappers, or robotic palletizers depending on the required level of automation.

- Control System (PLC & HMI): The brain of the operation. A Programmable Logic Controller (PLC) manages the sequence, timing, and synchronization of all components. A Human-Machine Interface (HMI), typically a touchscreen panel, allows operators to set parameters (length, coil dimensions, strap positions), monitor production, manage recipes, and diagnose issues.

Design Emphasis: Industrial-grade construction using robust steel frames, quality bearings, and durable components is vital for longevity in demanding production environments. Guarding and safety systems (light curtains, emergency stops) compliant with relevant standards (e.g., CE, OSHA) are non-negotiable.

3. Technical Specifications Deep Dive

When evaluating these machines, specific technical data points are critical for matching the equipment to production needs. Here’s a typical range of parameters (Note: Actual specifications vary significantly by model and manufacturer):

- Applicable Cable Diameter: 3mm - 30mm (Depending on model configuration)

- Maximum Coil Outer Diameter: 300mm - 800mm

- Adjustable Coil Inner Diameter: 150mm - 400mm

- Adjustable Coil Width (Traverse): 50mm - 300mm

- Maximum Coil Weight: 20kg - 100kg+

- Winding Speed: 0 - 200 m/min (Variable, dependent on cable type and coil size)

- Length Measurement Accuracy: ±0.2% (Typical)

- Strapping Material: PET or PP strap

- Strap Width: 9mm - 16mm (Common ranges)

- Number of Straps per Coil: 1 - 4 (Programmable)

- Cycle Time: 20 - 60 seconds per coil (Highly dependent on length, number of straps, and handling)

- Control System: PLC (e.g., Siemens, Allen-Bradley, Mitsubishi) + Touchscreen HMI

- Power Requirements: 380V/480V 3-Phase, 50/60Hz (Typical, model specific)

- Compressed Air Requirement: 6-8 bar (For pneumatic components)

Understanding these specifications allows for direct comparison between models and ensures the selected machine can handle the required product range and production volume.

4. Automation and Control Systems: The Nerve Center

Modern automatic winding and packing lines rely heavily on sophisticated control systems:

- PLC Control: Provides robust, real-time control over all machine functions, ensuring precise synchronization between winding, cutting, strapping, and transfer.

- HMI Interface: Offers intuitive operation. Operators can easily input parameters for different cable types and coil sizes, saving them as recipes for quick changeovers. The HMI also displays production data (coils produced, total length), machine status, and alarm messages for troubleshooting.

- Servo Drives: Often used for critical motion control axes like the traversing system and sometimes the main winding drive, offering high precision, speed control, and repeatability compared to standard induction motors.

- Sensors: Various sensors detect cable presence, coil position, strap tension, and safety guard status, ensuring smooth and safe automatic operation.

- Connectivity: Increasingly, machines offer Ethernet/IP, Profinet, or other communication protocols for integration with factory MES (Manufacturing Execution Systems) or ERP (Enterprise Resource Planning) systems, enabling real-time production monitoring and data logging.

5. Materials Handling: Strapping and Packing Choices

The choice of strapping and packing method depends on the cable type, customer requirements, and downstream logistics:

- Strapping:

- PP (Polypropylene): Cost-effective, suitable for lighter coils and general-purpose applications.

- PET (Polyester): Higher tensile strength and retains tension better, ideal for heavier coils or those subject to environmental changes during storage/transport. Strapping heads must be compatible with the chosen material.

- Packing:

- Film Wrapping: Provides basic protection against dust and moisture. Can be applied automatically after strapping.

- Boxing: Offers better protection and stackability. Requires integration with box erecting and closing systems.

- Palletizing: For high-volume production, robotic arms can automatically stack strapped coils or boxed coils onto pallets according to pre-programmed patterns.

6. Operational Advantages and ROI Considerations

Investing in an automatic cable winding, strapping, and packing line offers compelling advantages for fabricators:

- Labor Reduction: Significantly reduces the manual labor required for coiling, handling, and packing, freeing up personnel for higher-value tasks.

- Increased Throughput: Consistent cycle times and continuous operation lead to higher production output compared to manual methods.

- Improved Coil Quality: Automated winding ensures consistent coil dimensions, layering, and tension, leading to a more professional product appearance and easier handling for the end-user. Precise length measurement minimizes material waste.

- Enhanced Consistency: Automated strapping applies consistent tension and position, ensuring coil integrity during handling and shipping.

- Improved Safety: Reduces risks associated with manual handling of heavy coils and repetitive tasks (e.g., manual strapping). Fully guarded systems protect operators.

- Reduced Material Waste: Accurate length measurement and optimized strapping minimize give-away and scrap.

Return on Investment (ROI): While the initial investment is significant, ROI is typically achieved through labor savings, increased output, reduced waste, and improved quality control. A thorough analysis considering current costs versus the automated system's operational efficiency is essential.

7. Personal User Experience Insights & Considerations

From an operator's and maintenance perspective, several factors influence the daily experience with these machines:

- Ease of Setup & Changeover: Modern systems with recipe management via HMI significantly reduce the time needed to switch between different cable products. Clear interfaces and straightforward mechanical adjustments are key.

- Reliability & Maintenance: Look for robust construction and high-quality components (e.g., brand-name PLCs, sensors, pneumatics). Access for routine maintenance (lubrication, strap coil changes, cleaning sensors) should be considered in the machine layout. Proactive maintenance schedules are crucial to minimize downtime.

- Operator Training: While automated, operators still require training on machine operation, parameter setting, basic troubleshooting, and safety procedures. Intuitive HMI design aids the learning process.

- Troubleshooting: Well-designed systems include comprehensive diagnostics via the HMI, helping operators or maintenance staff quickly identify and resolve issues (e.g., strap feed failure, sensor blockage, safety fault).

- Noise Levels: Winding and strapping processes can generate noise. Acoustic enclosures or operating environment considerations might be necessary depending on the machine design and location.

- Footprint: These integrated lines require considerable floor space. Ensure adequate room for the machine, operator access, material staging (input cable, strap coils), and output accumulation.

8. Integration into the Broader Production Line

An automatic winding and packing machine rarely operates in isolation. Effective integration involves:

- Upstream Connection: Often linked directly to an extrusion line or a large rewinding machine. Synchronization (e.g., dancer/accumulator systems or speed signaling) is crucial to match the output speed of the upstream process.

- Downstream Handling: Output needs to integrate with warehouse logistics, whether it's conveyor transport to a shrink-wrapping station, AGV pickup, or manual palletizing.

- Data Exchange: As mentioned, connectivity for production monitoring, quality control data logging, and inventory management is increasingly important for smart factory initiatives.

Conclusion: Automating for Competitive Advantage

The automatic cable wire coil winding, strapping, and packing machine is more than just a piece of equipment; it's a strategic investment in efficiency, quality, and safety for cable manufacturers and processors. By integrating multiple labor-intensive steps into a streamlined, automated process, these systems directly address key challenges in modern manufacturing. The detailed technical specifications, robust component design, and advanced control systems provide the precision and reliability needed to meet demanding production targets and quality standards. While requiring careful consideration of specifications, integration, and ROI, the adoption of such technology is often essential for maintaining a competitive edge in the global marketplace.