1. Streamlining Operations: The Need for Automation in Aluminum Profile Handling

Handling long, heavy aluminum profiles presents persistent challenges for manufacturers and distributors. The traditional manual stacking process, often seen in facilities like those in Mexico City, is not just labor-intensive but fraught with risks. Fabricators grapple with:

- Safety Hazards: Manual lifting and positioning of bulky profiles significantly increase the risk of finger, hand, and foot injuries.

- Product Damage: Inconsistent manual stacking often leads to misalignment, improper spacing, and surface damage (scratches, dents) – compromising the quality of the final product.

- Operational Inefficiencies: Offline handling disrupts workflow smoothness. Manually placing wooden dunnage (spacers) between layers is time-consuming, slows down the packing line, and drives up labor costs.

- Inconsistent Stack Quality: Manual stacking rarely achieves the uniformity required for stable transport and storage, potentially leading to stack collapse.

These factors directly impact the bottom line through increased worker compensation claims, material waste, and reduced throughput. Addressing these issues is crucial for competitiveness in the modern fabrication landscape.

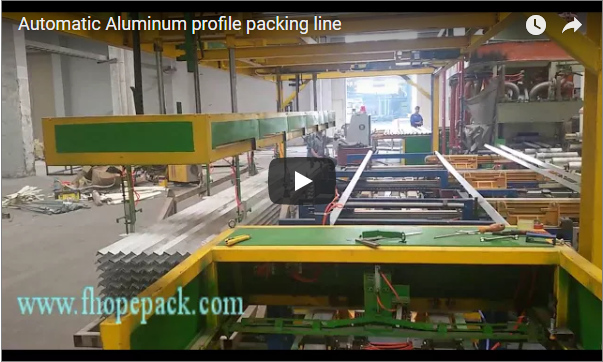

2. Introducing the Solution: The Automatic Aluminum Profile Packing Line

The video above showcases a state-of-the-art automatic aluminum profile packing line, specifically implemented to tackle these challenges head-on. This automated system represents a significant leap forward, optimizing the logistics of handling aluminum extrusions by prioritizing efficiency, safety, and product integrity.

3. Technical Deep Dive: System Capabilities and Customization

This automated solution, featuring an integrated automatic aluminum profile stacking lifter, is engineered to handle a diverse range of profile specifications directly from the extrusion or finishing line.

Key Handling Specifications:

- Profile Length: 3,600 mm to 6,400 mm (approx. 11.8 ft to 21 ft)

- Profile Width: 50 mm to 180 mm (approx. 2 in to 7.1 in)

- Profile Height: 30 mm to 150 mm (approx. 1.2 in to 5.9 in)

- Individual Profile Weight: 5 kg to 35 kg (approx. 11 lbs to 77 lbs)

System Power:

- Operates on a standard industrial 380V / 50Hz, 3-phase power supply (adaptable to regional requirements).

Customization is Key: Recognizing that no two fabrication plants are identical, this system is designed for flexibility. It can be precisely tailored to specific customer needs, including integration with existing upstream and downstream equipment, various plant layouts, and unique profile geometries beyond the standard specifications listed.

4. Core Features Driving Performance and Safety

The effectiveness of this aluminum profile packaging machine and stacking machine line stems from its intelligent design and automation features:

- Automatic Sensor Detection: Utilizes advanced sensors (e.g., optical, proximity) to accurately detect the presence, position, and orientation of each incoming profile. This ensures precise alignment before lifting and stacking, virtually eliminating collisions and misalignment that cause surface damage.

- PLC and Touch Screen (HMI): A robust Programmable Logic Controller (PLC) serves as the brain of the system, orchestrating all movements and sequences. The intuitive Human-Machine Interface (HMI), typically a touch screen panel, allows for easy operation, parameter adjustments (e.g., stack height, layer configuration), system monitoring, and diagnostics.

- Precision Arm Fork Lifter: This specialized mechanism gently lifts profiles, often using non-marring contact surfaces, and accurately places them onto the stack. Its controlled movement is far safer and more consistent than manual handling, protecting both personnel and product.

- Automatic Timber Block Feeding (Dunnage Placement): A dedicated subsystem automatically feeds and places wooden blocks or other specified spacers between layers at predetermined intervals. This crucial step ensures stack stability, prevents profile-on-profile contact, and significantly speeds up the cycle time compared to manual placement.

5. Tangible Benefits: From the Shop Floor to the Bottom Line

Implementing an automated aluminum profile packing line delivers substantial advantages:

- Drastically Improved Safety: Minimizes manual lifting and handling of heavy profiles, directly reducing the risk of musculoskeletal injuries and accidents.

- Enhanced Product Protection: Consistent, precise stacking with automated dunnage placement prevents scratches, dents, and deformation, leading to reduced scrap rates and higher quality output.

- Increased Throughput and Efficiency: Automation significantly accelerates the stacking process compared to manual methods, boosting overall line productivity and enabling faster order fulfillment.

- Labor Optimization: Frees up valuable manpower from repetitive, strenuous stacking tasks, allowing workers to be redeployed to more complex, value-added activities.

- Consistent Stack Quality: Produces uniform, stable stacks optimized for safe storage, handling, and transportation.

6. Take the Next Step Towards Automated Efficiency

Is your operation facing challenges with manual aluminum profile handling? Witnessing the inefficiencies and risks firsthand? It's time to explore the transformative potential of automation.

Contact us today to discuss your specific requirements. We can provide:

- A customized quote tailored to your profile dimensions and production volume.

- Further technical details and integration possibilities.

- A virtual or potentially on-site demonstration to see the system in action.

Experience how integrating an automatic aluminum profile stacking machine line can revolutionize your logistics, improve safety, protect your product, and boost your bottom line.

7. Frequently Asked Questions (FAQs)

1. How exactly does the automatic sensor detection prevent damage?

The sensors verify that the profile is correctly positioned before the lifting mechanism engages. If a profile is skewed or out of place, the system typically pauses or alerts the operator, preventing forceful contact or improper placement that could cause scratches or dents. They also ensure layers are built evenly.

2. Our plant uses different profile dimensions. Can the machine be adapted?

Absolutely. While the specifications listed cover a common range, the system is designed for customization. We work closely with clients to engineer the machine to handle their specific profile lengths, widths, heights, and weights, ensuring seamless integration into their production flow.

3. What level of training is needed to operate this automated line?

The system is designed with user-friendliness in mind. The PLC and touch screen interface provide clear controls and diagnostics. While initial operator training is provided and essential for safe and efficient operation, it's generally straightforward and focuses on operating sequences, basic troubleshooting, and safety protocols, rather than complex programming.

4. How does automated dunnage placement improve the process?

Manually placing timber blocks is slow, ergonomically challenging, and prone to inconsistency. The automated system places dunnage accurately and rapidly every time, ensuring stack stability and freeing the operator from this tedious task, significantly increasing the overall speed and efficiency of the packing line.

5. What is the typical footprint or space requirement for this machine?

The footprint varies depending on the specific configuration, maximum profile length handled, and integration with other equipment. We provide detailed layout drawings during the proposal phase to ensure it fits within your available plant space.