The video of the steel coil strapping machine operation.

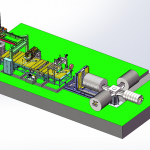

Components:

• Frame – The base structure that supports the entire machine. It is made of heavy duty steel to withstand the forces from strapping coils.

• Sealer head – Applies heat to seal the ends of the steel strap after it is wrapped around the coil. It contains heating elements, cooling fans and guiding components.

• Strapping head – Feeds the steel strap from the reel, wraps it around the coil and tensions it to the required tightness. It includes strap guide rollers, tension mechanism and cutter.

• Strap reel – Holds the roll of steel strap that is used for binding the coil. Reels can be manually loaded or automatically switched.

• Tension controller – Controls the tension applied to the steel strap to achieve the optimum binding force. Air or hydraulic cylinders provide the tensioning force.

• Safety guards – Cover moving parts and shield areas with high temperatures for operator protection.

Functions:

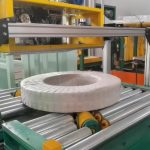

• Coils are placed on a turntable or conveyor and fed into the machine.

• The strapping head guides the strap from the reel and wraps it around the coil.

• The tension controller applies the required tension to the strap to securely bind the coil.

• The sealer head applies heat to seal the ends of the overlapping strap, crimping it in place.

• The strap is cut from the reel and the strapping head returns to the home position.

• The strapped coil is discharged from the machine.

In summary, steel coil strapping machines automate the process of applying binding steel straps to coils. The key components work together to tension, wrap, seal and cut the strap, providing a secure and consistent means of containment for handled coils.