info@fhopepack.om

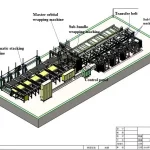

Aluminum Profile stretch wrapping machine

http://www.fhopepack.com/Automatic-horizontal-stretch-wrapper/E200-horizontal-stretch-wrapper.html

Supply list

| No. | Items | quantity |

| 1 | orbital Wrapping machine | 1set for each |

| 2 | Protection structure | 1set for each |

| 3 | Electrical cabinet, guardrail etc. | 1set for each |

| 4 | Program Control system | 1set for each |

| 5 | Manual & spare parts | 1set for each |

• Aluminum frame – The machine frame is made of rectangular aluminum profiles. Aluminum is used as it is light in weight but still strong and durable.

• Stretch film carriage – This carries the roll of stretch film and unwinds it while wrapping the products. It can move up and down the frame on sliding rods.

• Wrapping arm – An arm with a film guide moves around the products to apply the stretch film. The arm can rotate on a horizontal axis.

• Film unwind unit – Consists of a dancer roller system to control the tension of the film and an unwinder roller to feed the film.

• Film cutting unit – Uses a sharp blade to cut the film after completing a wrap.

• Control panel – Contains buttons to operate the machine functions like start, stop, film forward/reverse, wrapping speed adjustment etc.

• Hydraulic or pneumatic operator – To rotate the wrapping arm and move the film carriage up/down. Uses hydraulic oil or compressed air.

• Safety guards – Cover moving parts to prevent entanglement and operator injury.

• Stand or base – For mounting the machine frame on the floor. Made of steel or cast iron.

• The stretch film stretches as it’s wrapped around irregularly shaped products, conforming to their shape and providing a snug and secure wrap.

• Aluminum profiles are extruded aluminum beams that provide a sturdy but lightweight frame for the machine. They can be joined together using brackets, plates and clamps.

• The wrapping arm rotates at high speeds, up to 60-70 revolutions per minute, to efficiently wrap the film around products. The speed is adjustable.